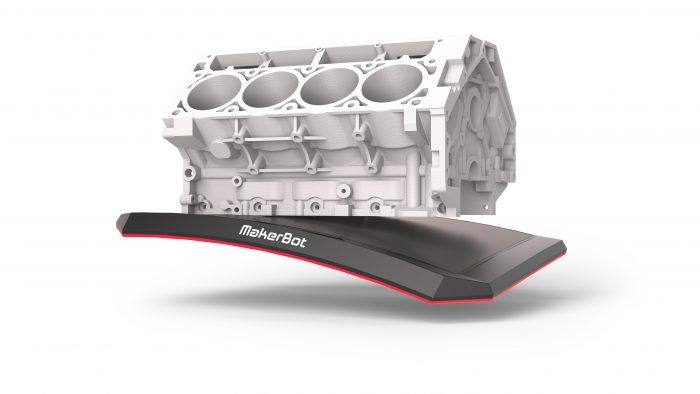

Brooklyn based MakerBot announced new 3D printing solutions yesterday (September 20), which promise to address the wider needs of professionals and educators. Coming shortly after the company’s team up with Samsung to bring 3D printing technology to classrooms across Europe, MakerBot have released a bunch of new products and services, including printers developed alongside Stratasys, new applications, filament and a Thingiverse platform for education.

What’s new?

The new printers on offer are their first ever professional grade printer, and an upgraded version of the Replicator Mini. The MakerBot Replicator+ and Replicator Mini+ have been re-engineered and tested to ensure improved performance. Branching out from consumer focused 3D printers, MakerBot is looking to make a comeback from previous woes. And when they boast 380,000+ hours of testing over the development process, they may not only work as advertised, their newest releases might even shine.

MakerBot are also offering new Print and Mobile applications designed to allow professionals to easily integrate MakerBot into their workflow, making things as seamless as possible. They are also hoping the applications will help educators introduce their students to 3D printing, a running interest from them in recent times, which is only bolstered by the launch of Thingiverse Education to discover 3D printing classroom content created by other educators. Lastly, the new Slate Gray Tough PLA Filament Bundle promises more durable, high-impact strength prototypes and fixtures for engineers. So let’s break all of that up and delve a little deeper.

Replicator+ and Replicator Mini+

Both 3D printers have been re-engineered to be faster, easier and more reliable printers. MakerBot worked closely with Stratasys during the extensive hours of testing that the machines underwent, implementing new, consistent procedures for better print quality, product lifetime testing and for validating test results.

The printers are supposedly faster and quieter than their predecessors, and feature larger build volumes. The MakerBot Replicator+ is approximately 30% faster, has a 25% larger build volume, and is 27% quieter than the MakerBot Replicator 5th Generation Desktop 3D Printer. The MakerBot Replicator Mini+ is approximately 10% faster, has a 28% larger build volume, and is 58% quieter than the MakerBot Replicator Mini Compact 3D Printer. The printers both come with the swappable MakerBot Smart Extruder+, which is designed and tested to provide improved performance over a longer period of time.

Accurate and predictable prints were high on the priority list of the designers and engineers of the new printers, which can only mean good things. Both printers claim to improve several aspects of print quality, including:

- print precision

- surface appearance

- reduced warping and curling.

This is made possible by re-engineered hardware, including the gantry, Z-Stage, build plate, and extruder carriage (for the Replicator+ only), in combination with fine-tuned firmware and a new slicing engine. The Replicator+ has the added feature of a flexible build plate, making separating your print from the plate that much easier.

The new Grip Build Surface ensures prints adhere better without the use of blue tape. This results in improved reliability, reduced warping and curling, and much cleaner prints as supports break away easily.

Canary recently had a chance to test MakerBot’s new solutions for professionals, and had a promising outlook on the services.

“Using a MakerBot Desktop 3D Printer helped us accelerate the development of the new Canary Flex by allowing us to prototype quickly and go through multiple iterations of the design,” said James Krause, Director of Industrial Design at Canary. “We were enthusiastic to test the new MakerBot Replicator+ and right away we noticed the faster workflow, as well as huge improvements to print quality and speed.”

The MakerBot Replicator+ has an MSRP of $2499 and the MakerBot Replicator Mini+ has a MSRP of $1299 and both are available now. MakerBot is offering the MakerBot Replicator+ at an introductory price of $1999 and the MakerBot Replicator Mini+ at $999 until October 31, 2016.

MakerBot Print and Mobile

MakerBot have developed connected 3D printing solutions to integrate desktop 3D printing into designers’ workflow, making the process hassle free. The new version of MakerBot Mobile features a guided setup, walking users through the entire 3D printer setup process. MakerBot Print has been designed to further streamline the entire experience.

- It has native CAD support, which eliminates the need for STL files, and will save a mountain of time for users.

- Users can now organize 3D files and multiple build plates into projects and easily email project files as attachments to collaborate with others.

- Storing information as complete project files instead of stand-alone model files allows users to save the print settings and build plate layout of one or more designs as one file.

- The new Auto Arrange feature automatically positions objects across multiple build plates to print them simultaneously or sequentially.

A new Print Preview option lets users review the Smart Extruder+’s path to make adjustments before printing a model. Users can either review each individual layer or play an animated video preview to see support material placement and validate that small features are printable.

MakerBot Print and the new MakerBot Mobile app support different office or classroom setups by building upon MakerBot’s remote monitoring and printing capabilities. Everyone from small companies to large schools now have the opportunity and flexibility to control and monitor multiple 3D printers remotely through live camera feeds and print status updates. Both applications are available now.

New filament

The new Slate Gray Tough PLA Filament Bundle is geared towards professionals to create durable, high-impact strength prototypes and fixtures that save time and money in testing. It is bundled as three spools of the filament, along with the MakerBot Tough PLA Smart Extruder+. The new filament fuses the best characteristics of PLA and ABS, being strong, easy to print and slightly more flexible to avoid breakage.

“The new MakerBot Tough PLA is a workhorse for functional printing. We mainly use it for prototyping parts and jigs for product cycle testing,” said Mack Mor, Senior Product Engineer at OXO, who’s been testing MakerBot Tough PLA over the past months. “The flexibility is key for parts that don’t break, even with thin features that would normally be troublesome. The interlayer adhesion is strong, but the raft is still super easy to remove. The material also slides well so it is good for snap fits.”

The Slate Gray Tough PLA Filament Bundle has a MSRP of $379 and is available now.

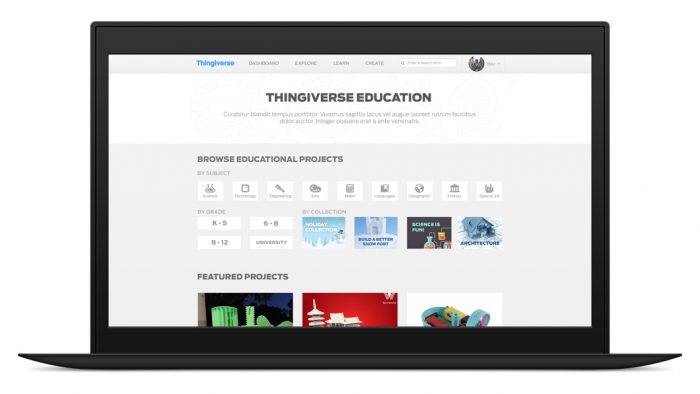

Thingiverse Education

The new platform is designed to allow educators to connect with each other to learn 3D printing best practices and exchange knowledge, already offering over 100 lesson plans created by other educators and vetted by MakerBot’s education and curriculum experts. The interface is easy, and lessons can be filtered by subject, grade or standard, and in true Thingiverse fashion, can be remixed to match specific learning goals.

“We believe that Implementing 3D printing in the classroom can only be successful if the technology complements a teacher’s goals for their students,” said Drew Lentz, MakerBot Learning Manager. “With a new section of Thingiverse dedicated to educational content, teachers can engage in a rich community of educators to find lesson plans, resources, and to find more ways to use 3D Printing in the classroom than ever before.”

This is a lot of news and products to process and put faith in, especially from a company with a past like MakerBot’s. Their questionable history of failed innovation could help them learn from their mistakes, however, and lead them to truly innovate the industry.

“We have gone through a cultural shift here at MakerBot over the past year, where listening and understanding the needs of our customers are cornerstones of our company. As a result, we’ve gained an in-depth understanding of the wider needs of professionals and educators that has informed our product development process,” said Jonathan Jaglom, CEO of MakerBot. “Our new solutions for professionals and educators are based on feedback addressing how we could accelerate and streamline the iterative design process and make teaching with a desktop 3D printer easier and more effective.”

Featured image: MakerBot