Vader Systems, LLC may not be a 3D printing enterprise all readers are familiar with, but for visitors to Chicago’s IMTS there is an opportunity to rectify this situation. The New York based company unveiled their first commercial liquid jetting at the show on Monday.

While recent years have seen a deluge of new entrants into the thermoplastic extrusion based 3D printer market, the same is not true in the metals space. Vader Systems and their MK1 Experimental metal 3D printer are changing this, and also bringing a new 3D printing technique along with them.

I spoke with Zach Vader, co-founder of Vader Systems and the inventor of the liquid metal jet 3D printer. Standing in front of the 9 foot long machine he explains how the process works;

“So, what we do is we take in wire, metal wire feedstock that gets melted into a ceramic nozzle. This makes a small pool [weighing] about 2 grams , the metal is always molten in the nozzle and then we use electromagnetism to induce a current and induce a radial inward force that produces a droplet. We do that ever time we send an electrical pulse, right now we’re doing pulses at a rate of a thousand times a second. So that’s 1,000 droplets a second and that gives us our high deposition rate.”

Making 3D metal printing more accessible

The feedstock for this 3D printer is 0.09 mm wire. The decision to use wire came about because Zach grew frustrated with the cost of metal powder bed 3D printers, where the special feedstock of spherical metal powder can prove prohibitive. Using wire means that the input cost is lowered to nearer to that of a commodity. The company claim the result is a 90% reduction when compared to the cost of fabricating with power bed techniques.

The company have a patent pending and I asked Vader about the IP behind the process. The IP is “specifically around the MHD system. The magentohydrodynamics system, that is used the electromagnetism to propel the metal.”

The company are currently testing MHD and the MK1 experimental 3D printer with the Rochester Institute of Technology (RIT) university. Vader says, “they are our first customer,” and that RIT have purchased a machine. By the end of Monday several show attendees had expressed an interest to purchase an MK1 according to a spokesperson for the company.

The applications for MHD depend on the material in use. Presently Vader Systems are, “just working with aluminum, and it’s alloys right now.” This material, “will have application in automotive, aerospace and a lot of other low volume/high complexity applications”. The specific aluminum alloys used are 4043, 6061 and 7075.

The company plans to move to using metals that require greater temperatures to melt, these include copper, brass and gold.

The team showed me a small, approximately 5 cm high by 3 cm wide, part they had produced earlier. The build time for this part was approximately 4 minutes. Marketing material for the company lists a planned deposition rate of 5 lbs of aluminum per hour, I asked Vader how the company achieves this speed.

“It’s a fast process because of the amount of material that we are able to deliver in the molten state. We’re using a 200 micron droplet size and firing a thousand of those a second, this means you can lay down about a pound an hour of material.”

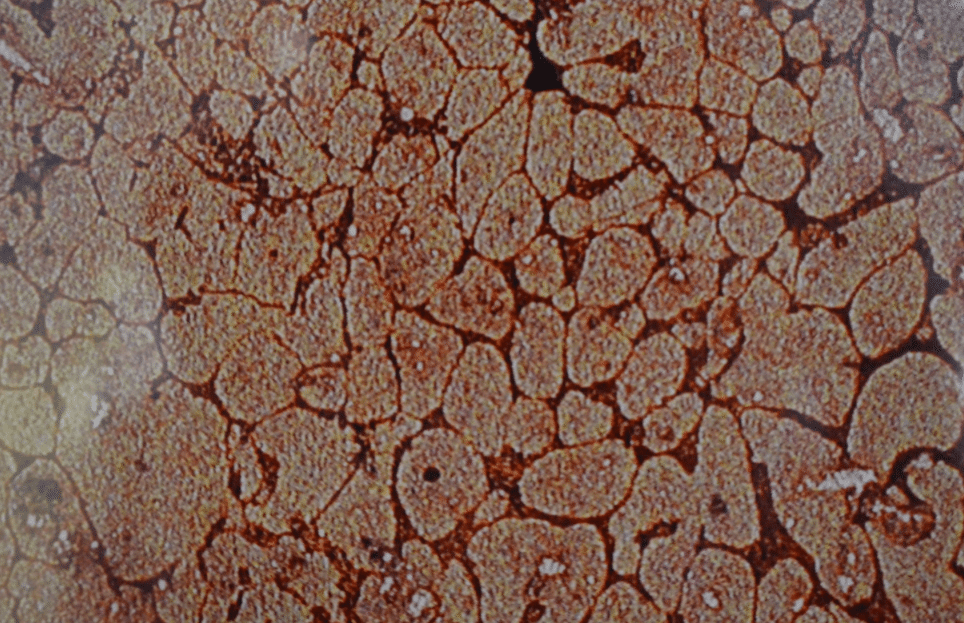

Aside from the speed, part density is a critical factor in the widespread adoption of 3D printing by industry. Pores, or gaps, inside a part can lead to structural weakness and may result in the failure of a component. Vader says, “we were always telling people that it was going to be very high part density, but just recently with the early results for RIT, it turns out that yes we’re almost 100% dense.”

An image illustrating these results is available for inspection at the Vader Systems booth. At the 500 um resolution the micrograph picture shows the metal droplets have solidified with very little porosity. “The interior structure shows a striking lack of visible layering or columnar structure,” reads the caption.

I asked Vader about the next steps for the company.

“Right now we have five machines up for grabs. Actually three now as two have been claimed. Three are left for the end of this year. And next year we’ll have, at the beginning of the year Q1 – Q2 ,25 slots available for purchase and machines will be selling for $400,000 if you buy the experimental version. And after that the price will be $500,000 for the production variety.”

Visitors to IMTS can see the MK1 Experimental in action by visiting booth N-85 in the North building.

Featured image: Michael Petch