An anaesthesia team in Israel recently used 3D printing and virtual reality to produce an exact model of the airway of a 7-year-old girl, as part of an operation to remove a section of her lung.

Suffering from a bone and soft tissue cancer that had spread to her lung, the young girl required part of her right lung to be removed. In order to prepare properly for the operation, her doctors at the Tel Aviv Sourasky Medical Center leveraged a virtual reality program of her airway and lungs, and also an exact 3D printed plastic model so they could practice the procedure beforehand.

“Despite extensive adult experience, our familiarity with one lung ventilation (OLV) in the very young paediatric population is limited,” explains Dr Ruth Shaylor of the Division of Anesthesia, Pain and Intensive Care, Tel Aviv Sourasky Medical Center, the lead author on the report.

“We used a combination of 3D printing and virtual reality bronchoscopy to develop a personalised airway plan reducing the potential for trial and error in airway manipulation during the operation.”

3D printing a personalised airway plan

The condition afflicting the young girl, spreading to her lungs, is known as Ewing’s Sarcoma, a rare type of cancer that affects bones or the tissue around bones.

When preparing for an operation on the patient, a chief concern of the doctors surrounded her small size, as she was just 18kg at the time of the operation. Potential complications could arise with the use of conventional tubing and devices often suited for lung operations in older patients.

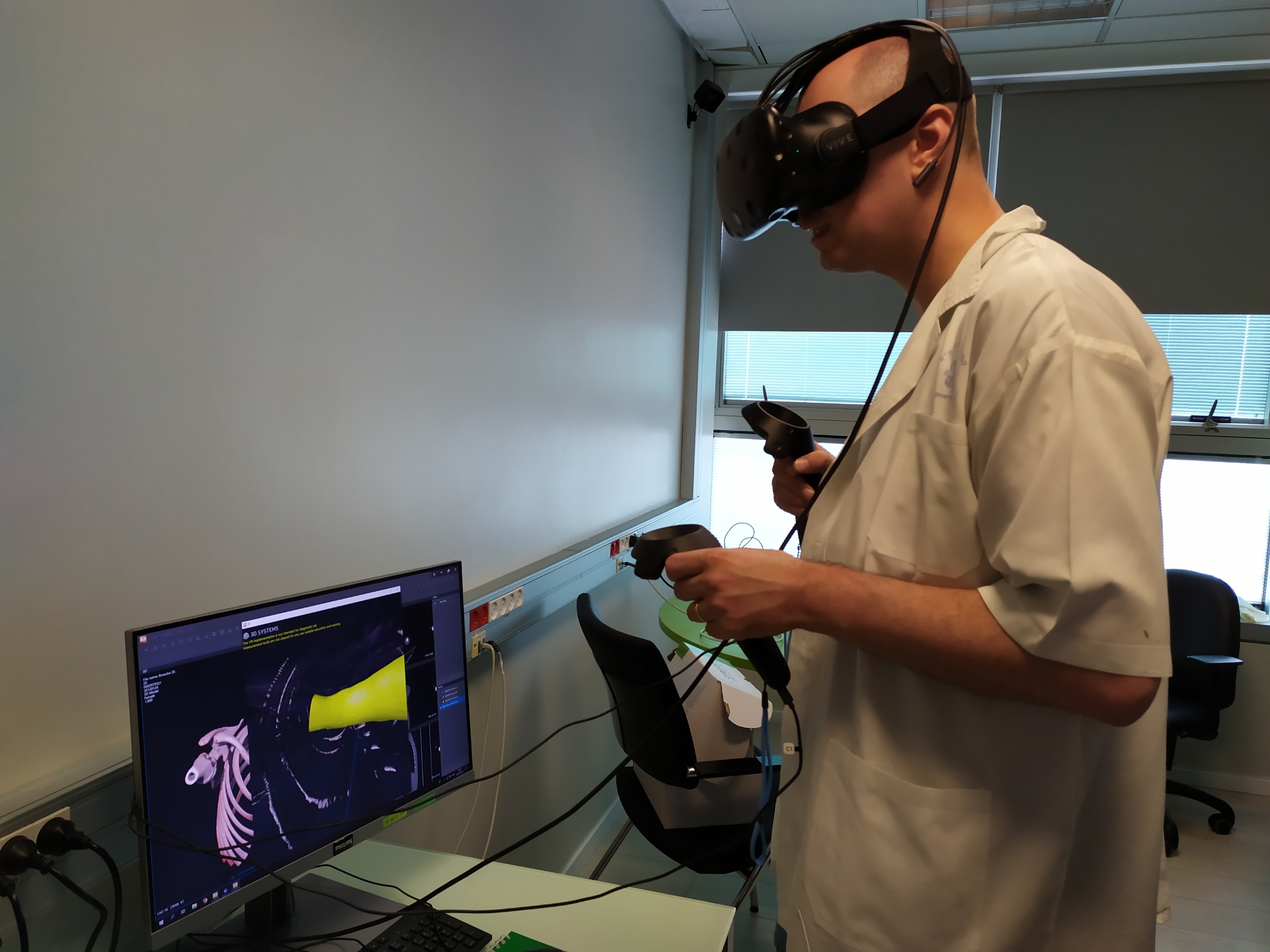

As such, the doctors opted to use CT scans to create a virtual reality program of her airway/wind pipe and lungs. The day before surgery, the treating anaesthesiologist spent time on the virtual reality simulator familiarizing himself with the patient’s airway anatomy.

Thereafter, a model was 3D printed and used to formulate an individualized airway plan. The 3D model was made of hard plastic, as anything more flexible might be inaccurate, meaning something larger than the patient could tolerate might be used.

The VR and 3D printed model meant that some of the equipment originally planned for the operation was altered. Once the girl was placed under anaesthesia, they were able to safely isolate and ventilate her left lung and perform the surgery to remove part of her right lung. “During the procedure, the treating anaesthesiologist reported a good correlation between the patient’s anatomy and the VR model, allowing the operation to proceed as planned,” comments Dr Shaylor. “At the end of the procedure, the tubing and equipment was removed easily and the patient made an uneventful recovery.”

Dr Shaylor continues, explaining that to date, 3D printing in anaesthesia has been mainly used for educational purposes, however it has the potential to further aid operations: “3D printing in anaesthesia is underutilized for patient-specific pre-operative planning. The same applies to the use of virtual reality in anaesthesia. We successfully combined both technologies to produce a personalized airway plan for a child patient. The final airway plan was substantially different to the plan developed using standard imaging techniques. This reduced the number of attempts at lung isolation that would have otherwise been performed on the patient.”

Patient-specific medical care

There have been numerous occasions and initiatives established where 3D printing has been used for patient-specific pre-operative planning, helping surgeons carry out their procedures.

For example, the Veterans Affairs (VA) Puget Sound Health Care System announced a two-year partnership with the University of Washington School (UW) of Medicine in 2019 to create patient-specific 3D printed models to help treat mitral valve disease, a complex heart abnormality.

GE Healthcare and Formlabs have also announced a collaboration aiming to make it easier for clinicians to 3D print patient-specific anatomical models from imaging data.

3D printed, patient-specific medical devices have also been used beyond pre-operative planning, with applications within procedures themselves. Earlier in 2020, 3D printed patient-specific airway stents developed by a doctor at Cleveland Clinic received clearance from the FDA for implantation in patients.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows pre-operative planning with the 3D printed model. Photo via Dr Ruth Shaylor.