GE Healthcare, the medical equipment subsidiary of multinational conglomerate GE, and SLA and SLS 3D printer provider Formlabs have announced a collaboration aiming to make it easier for clinicians to 3D print patient-specific anatomical models from imaging data.

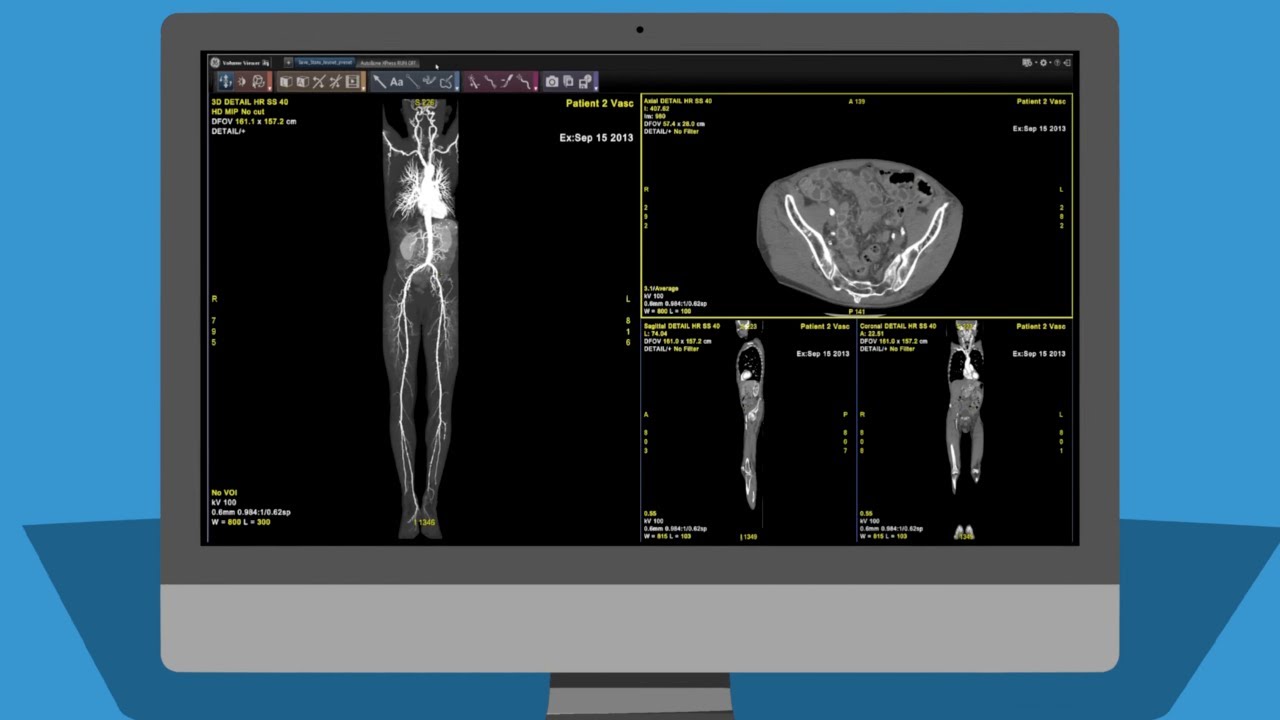

Through the partnership, both companies will be offering radiologists specializing in cardiology, oncology, orthopedics, neurology, and other areas an end-to-end GE Healthcare/Formlabs bundle for producing anatomical models. Included within the bundle are Formlabs 3D printers and materials, and GE Healthcare’s Advantage Workstation (AW) advanced visualization software for preparing the 3D models for printing.

“When time is of the essence, GE Healthcare solutions help clinical imaging specialists get the diagnosis correct quickly and push the critical information they create into the hands of the broader care team,” commented R. Scott Rader, general manager of GE Healthcare Additive Solutions. “The virtual reality renderings clinical imagers see every day in radiology reading rooms on AW can now be exported via AW 3D Suite in seconds, imported into Formlabs PreForm, and printed right at the site of care to add the sense of touch to what members of the care team see. “

“This first step with Formlabs can help break down time and cost barriers to adoption of on-premises printing while empowering richer communication amongst care teams and their patients.”

All-in-one package for 3D printing anatomical models

GE Healthcare’s AW advanced visualization tools are specifically designed for the medical community, to help radiologists create 3D models of normal and pathological anatomy using automation techniques. Leveraging a diagnostic workflow, AW is intended to speed up the often labor intensive process of preparing image data into 3D printable files. This will reportedly help to reduce the time it takes to create STL and OBJ files required for 3D models from hours to minutes.

Key to the AW software is that it is compatible with all imaging modalities, including CT, MR, PET, SPECT and Interventional. Bringing these techniques together, clinicians are able to boost their productivity with over 55 clinical applications, presented on a consistent user interface that can be viewed via a Workstation, RIS/PACS, laptop, or PC.

Coupled with Formlabs technology, including the Form 3B 3D printer launched last month in November, GE Healthcare and Formlabs aim to reduce the time and cost for clinicians producing detailed anatomical models at the point-of-care. Also included in the package is Formlabs’ PreForm print preparation software, and over 20 proprietary resins. This will allow radiologists and biomedical engineers to serve various surgical specialties within a single workflow. Recently, Formlabs acquired Spectra Group Photopolymers LLC, the company’s primary material supplier since 2012, and plans to begin production of new biocompatible polymers.

Further time savings can be achieved using new Formlabs features, like remote 3D printing, and Light Touch Supports that allow for nearly immediate support removal. Formlabs is also providing a GE Healthcare exclusive service where it is offering training for customers in North America and Europe. The company aims to get these customers printing anatomical models onsite at the hospital in two days.

“This collaboration represents an important milestone for the medical 3D printing community and will hopefully serve as a catalyst for its growth. Our clinical customers should be able to serve more patients, more efficiently, with trusted, reliable, and intuitive technologies,” adds Gaurav Manchanda, Director of Healthcare at Formlabs.

On-site 3D printing at hospitals

3D printed anatomical models allow clinicians to accurately visualize patient anatomy and disease, as it can be created according to specific 3D data gathered from the patient. This can help to enhance physician training and reduce procedure time in the operating room by allowing surgeons and clinicians to plan their operation. Further advantages offered by the models include improved communication within the medical team, better tangible case-based teaching models, and enhanced patient education.As such, great effort is being made to support the widespread adoption of point-of-care 3D printing in hospitals.

For example, the Veterans Affairs (VA) Puget Sound Health Care System and the University of Washington (UW) School of Medicine recently announced a two-year partnership to develop standardized pathways for creating patient-specific 3D printed models at hospitals. Speaking with Dr. Beth Ripley, a VA Puget Sound radiologist, she explains that “In the near future, we anticipate significant growth in the number of both public and private hospitals acquiring 3D printers. And we hope the workflows we create will help facilitate adoption of best practices at these new health care facilities.”

In August 2019, Northern Ireland-based medical manufacturing service provider axial3D revealed it was providing Newcastle Hospitals NHS Foundation Trust with an on-site 3D printing lab. It will be used to produce patient-specific models for pre-surgical planning.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed a replica of a human heart. Photo via GE Healthcare.