Austrian ceramic 3D printing specialist Lithoz is set to highlight its latest cutting-edge innovations in multi-material 3D printing during Formnext 2023.

In Frankfurt, the company will showcase its revolutionary multi-material CeraFab Multi 2M30 LCM 3D printer in a world trade show premiere. This will be presented alongside a wide variety of multi-material 3D-printed parts.

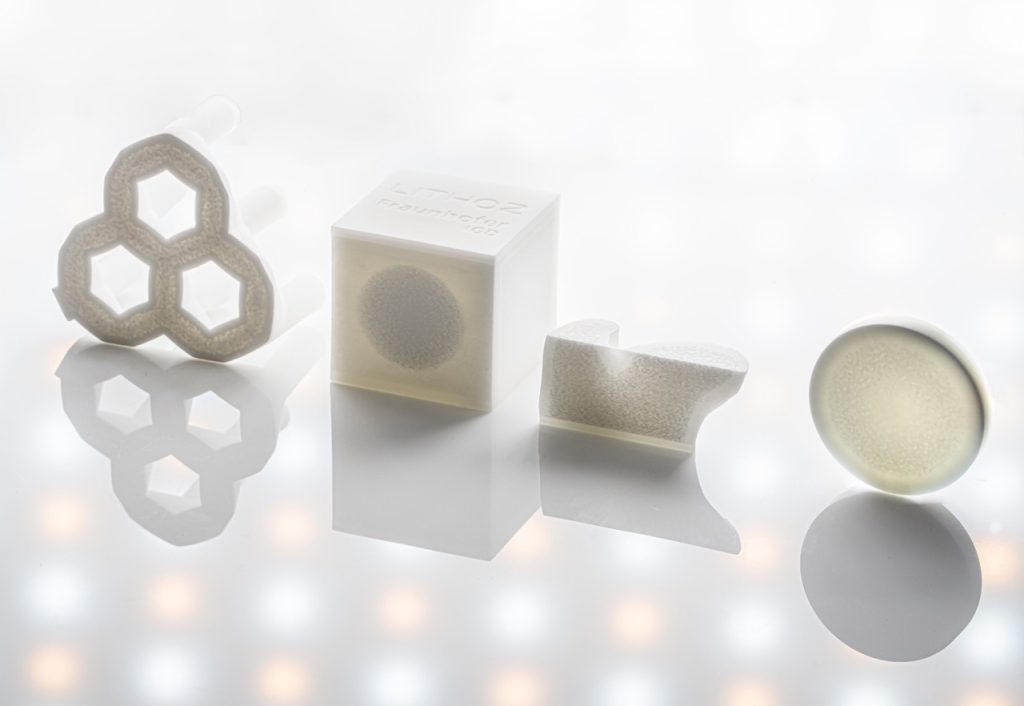

The CeraFab Multi 2M30 can 3D print two different materials within a single layer. This enables the production of highly complex multifunctional parts, by combining ceramics with metals or merging two ceramic materials with different properties. During Formnext, these multi-material parts will be available for visitors to pick up and examine, for a close-up ‘touch and feel’ experience.

The company will also introduce the Ceramic AM Factory. Offering a network of experienced contract manufacturers already using LCM technology in serial production, Lithoz presents an impressive array of new parts for serial production made by Bosch Advanced Ceramics, Steinbach and SiNAPTIC printed on Lithoz CeraFab System printers

In addition, following the overwhelming interest in 3D-printed healthcare applications using technical ceramics at last year’s Formnext, Lithoz will display a broad range of innovative 3D-printed ceramic parts for medical and dental applications. These parts include a range of natural-looking disilicate dental restorations. Furthermore, Lithoz will showcase a special display of bioresorbable ceramics, such as hydroxyapatite, tricalcium phosphate and multi-material medical parts combining both. These components will highlight how ceramics and groundbreaking 3D printing technology can be combined to elevate surgical precision and patient well-being.

Multi-material 3D printing with the CeraFab Multi 2M30

Formnext 2023 will be the CeraFab Multi 2M30’s first trade show appearance on the world stage, following its 2020 launch.

This powerful LCM 3D printer can simultaneously 3D print two materials within a single layer. This enables changes in a part’s composition, allowing for the production of customizable functionally-graded structures that would otherwise be impossible to fabricate.

Opposing materials can be flexibly and functionally combined into a single 3D-printed part, even including ceramic with metal. This allows for the production of ceramic-metal components with opposing properties, including alternating conductivity and insulation between layers. Parts that possess an otherwise unachievable level of detail and complexity can also be 3D-printed.

With the arrival of “The Ceramic AM Factory,” Lithoz will also present an impressive array of new parts for serial production at Formnext 2023. Here, parts produced by Bosch Advanced Ceramics, Steinbach and SiNAPTIC using the company’s LCM technology will be available to examine in a close-up “touch and feel” setting.

This showcase will highlight the success of the company’s LCM technology as a scalable solution for the industrial mass production of precisely reproducible and ultra-detailed high-performance ceramic parts. Lithoz experts will also be on hand in Frankfurt to provide additional information and insights into this wide range of scalable components.

Next-generation multi-material 3D printing for medical applications

Formnext 2022 saw substantial interest in 3D-printed healthcare applications using high-performance bioceramics. To meet this growing area of interest, Lithoz will this year showcase a broad range of natural-looking lithium disilicate dental restoration components and bioresorbable ceramic implants made from hydroxyapatite.

One innovative application impressively highlighting the potential of the CeraFab Multi 2M30 within the medical industry is the production of multi-material jaw augmentation components. Produced as part of the EU-funded INKPlant Project, this novel application will be showcased by Lithoz for the first time during Formnext 2023.

Atrophy, missing bone volume, of the jaw is the long-term result of tooth loss. This loss of bone also prevents the replacement of these teeth with the current gold standard – dental implants – necessitating surgery to augment the volume of local bone with either harvested bone grafts or other materials.

One very promising approach is treatment with 3D-printed bioresorbable multi-material patient specific implants. These parts are made to perfectly integrate with the patient’s anatomy. The INKPlant Project aims to develop this new treatment approach by combining the best properties of two established bioresorbable augmentation materials in one custom 3D-printed implant: tricalcium phosphate and hydroxyapatite.

Tricalcium phosphate promotes the fast ingrowth and generation of the jawbone due to its faster resorption time. The hydroxyapatite shell ensures the mechanical and volume stability of the implant during healing and replaces the membrane as a barrier against premature ingrowth of soft tissue, which would prevent bone formation. Only Lithoz multi-material printing has made this combination of materials in one part possible. This implant is designed to deliver predictable results and ensure a quicker surgical procedure with reduced pain and swelling, benefitting the patient.

Want to learn more? Visit Lithoz at booth D48, Hall 11.1, during Formnext 2023.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows innovative copper and glass-ceramic components 3D printed with the Lithoz CeraFab Multi 2M30, which can combine ceramics with metals in a single part. Photo via Lithoz.