Finnish 3D printer manufacturer miniFactory has launched its new industrial-level FFF 3D printer, the miniFactory Ignite. A highly cost-effective high-performance 3D printer, the Ignite boasts a 200℃ smart heated build chamber, substantial 600 x 400 x 400 mm build volume, and advanced quality assurance technology.

Specializing in the production of high-performance 3D printers, miniFactory has delivered Ultra series 3D printers to customers in more than 20 different countries. The addition of the Ignite into miniFactory’s portfolio reportedly allows the company to serve customers in more industries.

Indeed, miniFactory’s new industrial 3D printer also offers wide-ranging high-performance material compatibility. The Ignite is also compatible with the newly developed ISO/ASTM 52920:2023 standard. As such, the 3D printer is optimized for use in aerospace, railway, defense, marine, and general engineering applications.

Key features of the miniFactory Ignite

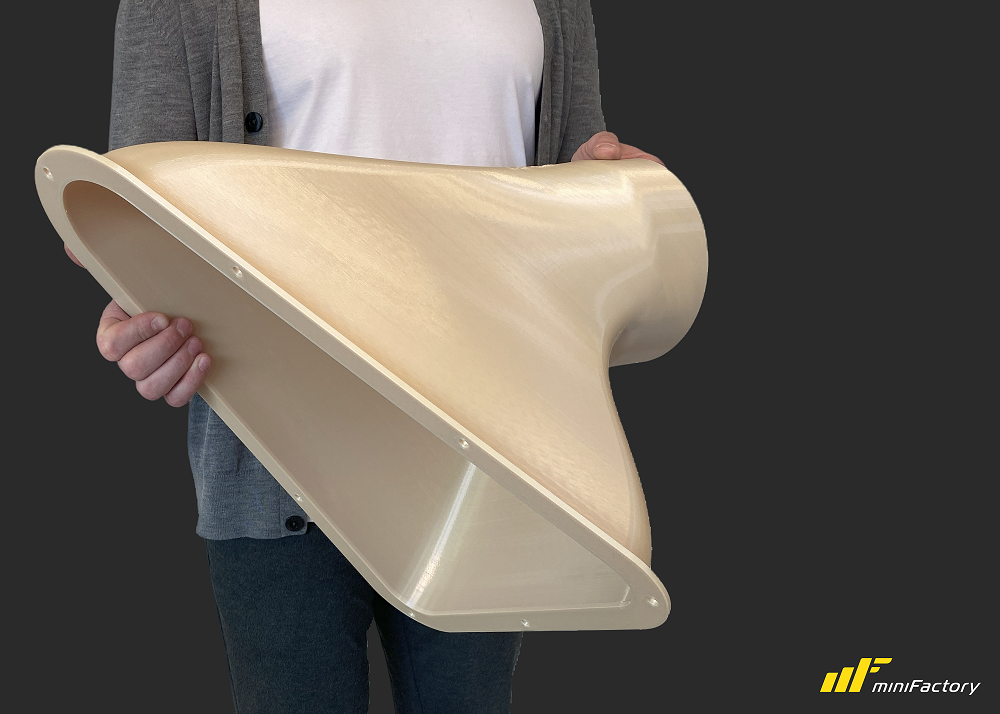

The Ignite stands out in the high-temperature 3D printing segment with its exceptionally expansive build volume, boasting dimensions of 600 x 400 x 400 mm. The impressive build size of the Ignite opens doors to a vast spectrum of industrial applications, encompassing the manufacturing of functional prototypes, large-scale models, and end-use parts.

Thanks to its advanced AARNI QA process monitoring technology, the Ignite is optimized for high-productivity 3D printing. The Ignite also enables remote control functionality and incorporates an on-board camera for real-time 3D print monitoring.

The Ignite’s high-temperature, 200℃ build chamber is also notable, enabling users to 3D print with a wide-range of high-performance, industrial materials. For instance, the Ignite is optimized for use with ULTEM AM9085F, a widely used high-performance material. This material is ideal for demanding industries such as railway, marine, defense and aerospace.

The Ignite is compatible with ULTEM AM9085F, PACF, PC, ABS, ASA, PEKK-A, PVDF, PEEK, PEKK, and a wide range of composite materials. This makes it ideal for the production of high-performance components for a variety of industrial applications.

According to miniFactory, the company is on a mission to make high-performance industrial 3D printing cost efficient. “You get all the benefits of high-performance technology without breaking the bank. The Ignite is built to last and it’s an investment that pays off over time,” the company states.

The world premiere of Ignite will take place during Formnext 2023 between 7-10 November, and will be located at the miniFactory stand in hall 12.1-F101.

Deutsche Bahn leverages the miniFactory Ultra 2 3D printer

miniFactory also offers the Ultra 2 3D printer, designed for top-tier applications where quality is key. One Ultra2 customer is Deutsche Bahn (DB), Germany’s national railway company. In a partnership spanning two years, DB leverages miniFactory Ultra 3D printers to manufacture obsolete spare parts for trains using EN45545-certified materials like ULTEM AM9085F.

Notably, it was recently announced that DB had become one of the first companies in the world to be certified according to the newly established ISO/ASTM 52920:2023 standard. Developed by TÜV NORD GROUP, this standard seeks to ensure quality assurance for industrial additive manufacturing.

Both Ultra and Ignite 3D printers, from miniFactory, are ISO/ASTM 52920 compatible. This highlights the ability of miniFactory technology to meet the highest industry benchmarks and serve a range of industrial verticals.

Technical specifications

| 3D Printer Name | miniFactory Ignite |

| Chamber Temperature | 200°C |

| Platform Temperature | 200°C |

| Extruder Temperature | 480°C |

| Mechanics | AC-SERVO MOTORS & BALL SCREWS CLASS C3 |

| Repeatability | 0.016MM/600MM |

| Max 3D Print Speed | 300MM/S |

| Nozzle Sizes | 0,4 – 1,0MM |

| Max Productivity | +150G/HR (TBD) |

| Extruders | 2, SEPARABLE EXTRUDERS ( SUPPORT MATERIALS) |

| Build Size | 600MM X 400MM X 400MM |

| Materials | ULTEM9085, PA, PC, ASA, ABS, PVDF, (PEKK, PEEK) + MORE + WIDE RANGE OF GF/CF COMPOSITES AND ESD POLYMERS |

| Build Platform | INTERNAL VACUUM SYSTEM |

| Leveling | FULLY AUTOMATIC CALIBRATION |

| UI | 10” TOUCH SCREEN |

| Safety | ACTIVATED CARBON FILTERING |

| Filament Diameter | 1.75MM |

| Cooling | LIQUID COOLING & AIR COOLING |

| Sensoring | JAM & RUNOUT SENSORS |

| Integrated Features | AARNI – QUALITY ASSURANCE TECHNOLOGY REMOTE CONTROL + ON-BOARD CAMERA MATERIAL DRYING CHAMBER SMART MAINTENANCE INTERVALS FULL SYSTEM STATISTICS |

| Slicing Software | SIMPLIFY 3D, CURA |

| Certification | CE, UKCA |

| 3D Printer Measurement | 155 X 85 X 175CM – 520KG |

| Power Requirements | 400V/16A 3-PHASE |

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the new Ignite 3D printer from miniFactory. Photo via miniFactory.