Scientists from the Leibniz Institute of Photonic Technology (IPHT) have designed a low-cost 3D printed microscope that can be customized to meet the needs of each user.

The ‘U2’ is built around a modular printable cube, on which academics can attach a combination of lenses, LEDs and camera parts, to suit their specific area of research. Having posted their design on GitHub, the team now hopes that adopters will build on the capabilities of their kit, and continue to improve the accessibility of complex scientific studies.

“We want to make modern microscopy techniques accessible to a broad public,” said Benedict Diederich, a PhD student at Leibniz-IPHT. “This build-it-yourself approach to teaching has huge potential, especially during the pandemic, when access to teaching materials at home is severely limited.”

The benefits of open-source microscopy

As the list of features demanded from microscopes by modern biological research has continued to grow in recent years, so has their price. Maintaining such complex equipment also requires significant training, and both these issues have caused cutting-edge imaging technologies to become limited to specialized laboratories.

Although there are more tailored alternatives on the market, they too can be costly, and difficult to modify or change. Additionally, ISO and Royal Microscopy Society (RMS) certification may have ensured high standards in these devices, but the scientists claim that they’ve also stifled any potential design innovation.

To counter this, the team has made the case for an “open standard,” that allows for devices to be developed that are capable of simple and rapid reconfigurations. Inspired by the accessible μ Cube and Flamingo microscopy kits, the Leibniz scientists have now designed their own device, that can be built for €100 to €400.

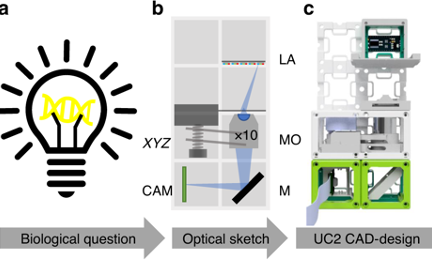

Designing, printing and applying the CR2

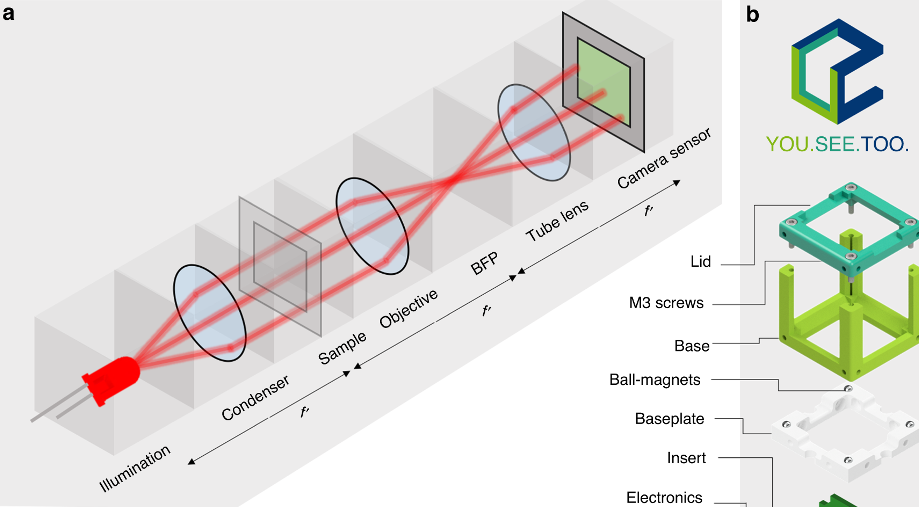

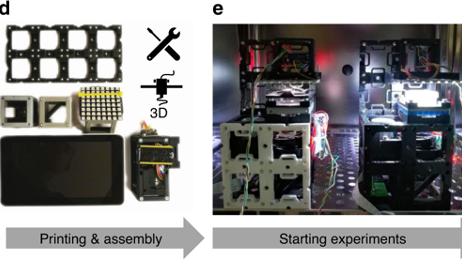

The team’s modular cube, which acts as the center of their device, was 3D printed into a base and a lid, in order to make adding plug-ins as easy as possible. A grid of neodymium ball magnets were then added to the microscope’s base plate, enabling it to act as a mounting point, and to be rotated in any given direction.

Once they’d designed the foundation, the team went on to develop a range of optical add-ons for it, and made them available online via a free MDK file. Through initial testing, the scientists also found that light settings and focusing mechanisms could be controlled wirelessly with various mobile devices, proving its compatibility.

Researchers based at the Free University of Berlin have since adopted the UC2 within their pathogen research study, where it proved capable of observing living cells in an incubator. According to Diederich, who helped build the microscope, the device also demonstrated significant practical advantages over its commercial competitors.

“Commercial microscopes that can be used to examine pathogens over a longer period of time cost hundreds or thousands of times more than our UC2 setup,” said Diederich. “You can hardly get them into a contaminated laboratory, from which you may not be able to remove them, because they cannot be cleaned easily.”

Elsewhere, in a study at Jena University Hospital, the UC2 has also helped researchers to develop a better understanding of how the immune system fights certain viruses. Consequently, the Leibniz team has concluded that their device is ideal for aiding bio-research, but they hope that it will be used as a teaching tool in future as well.

To make their microscope even more accessible, the scientists have now developed a kit called “The Box,” that’s been workshopped at schools in the U.S, UK and Norway. “The components can be combined to form a projector or a telescope; you can build a spectrometer or a smartphone microscope,” said Barbora Maršíková, the Box’s designer.

“We have even combined the UC2 with our smartphone,” added Emilia Walther, who tested the kit at her school. “This enabled us to build our own fluorescence microscope cost-effectively, without any major optical knowledge, and to develop a comparably simple method for detecting plastic particles in cosmetics.”

Using additive to develop advanced opticals

Although the Leibniz team’s modular design is different to many commercial microscopes, 3D printing itself has already been used to optimize optical devices in various ways.

A team from the University of Bath has developed an open-source design for a 3D printable “laboratory-grade” microscope, that could cost as little as $18. The ‘Open Flexure,’ has several advanced features such as motorized sample positioning, focus control and a precise mechanical stage.

Other researchers such as those from the University of Connecticut have used 3D printing to create ultra-high resolution microscopes. The team were ultimately able to fabricate a device that provided 3D images with twice the resolution of traditional Digital Holographic Microscopy (DHM) systems.

Elsewhere, scientists from RMIT University have attempted to maximize the accessibility of microscopy, by 3D printing a clip-on smartphone microscope. The filter enables users to view details of an object down to the size of 1/200th of a millimeter, potentially making it ideal as a point of care diagnostic tool.

Those interested in constructing the Leibniz team’s design, can access the files via the GitHub website.

The researchers’ findings are detailed in their paper titled “A versatile and customizable low-cost 3D-printed open standard for microscopic imaging.” The study was co-authored by Benedict Diederich, René Lachmann, Swen Carlstedt, Barbora Marsikova, Haoran Wang, Xavier Uwurukundo, Alexander S. Mosig and Rainer Heintzmann.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Leibniz team’s modular microscope as part of a workstation. Image via the Nature Communications journal.