3D printing continues to prove itself a valuable service for yet another large tooling and manufacturing company as James Tool starts offering 3D printing services in order to stay relevant within its industry sector.

As a leader in precision CNC machining and parts manufacturing, James Tool Machine & Engineering signals a continuing shift in the way that traditional manufacturing companies are seeing their roles change. Many tooling and machining companies are starting to understand that while 3D printing presents no danger of eliminating their businesses entirely, it is rapidly becoming a necessary part of the prototyping and manufacturing process.

“In order to stay on the cutting edge of manufacturing technology and continue to be competitive, it was a must for James Tool to invest in additive technology and offer these additional services to our customers,” said the president of James Tool, Jeff Toner. “We want our customers to really embrace additive manufacturing and see the benefits of this game changing technology. It is important for our customers to work with us to ensure the right technology and materials are being used when considering additive technology.”

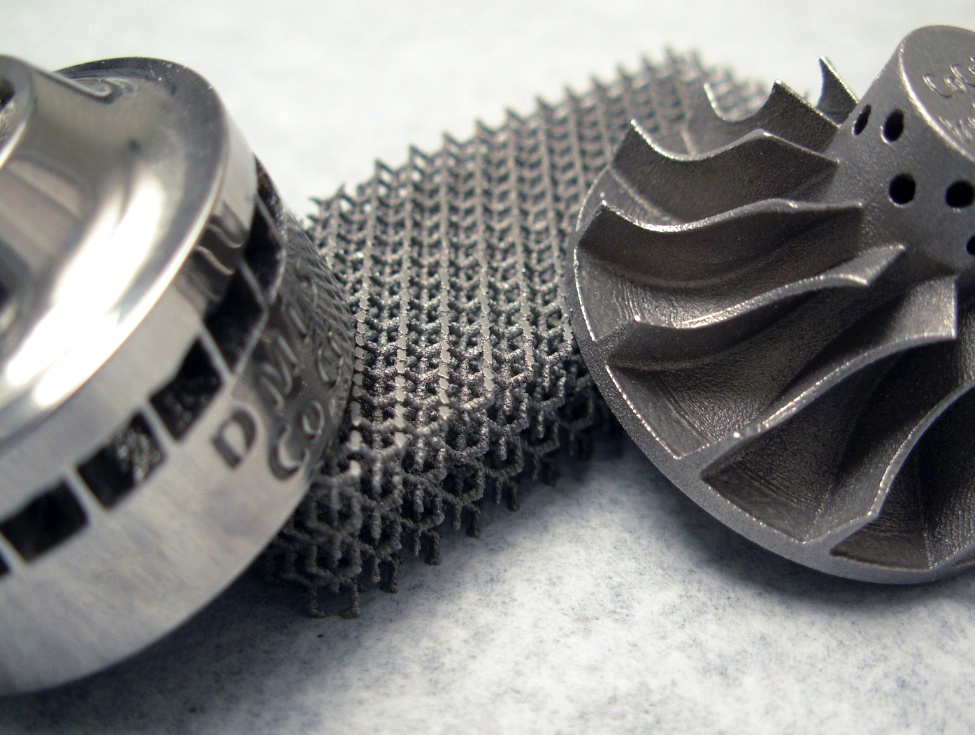

James Tool has started offering an entire line of additive manufacturing options, including fused deposition modeling, metal laser sintering, selective laser sintering and stereolithography. They’ve also launched a “THINK” advertising campaign aimed at helping their customers understand what 3D printing is and how it can help their businesses. The campaign focuses on the saved time and expense of using 3D printing to prototype. Rapid prototyping with 3D printing will produce workable prototypes in a matter of days, often times in hours, and it only costs a fraction of many traditional tooling methods. That makes it quite an added bonus to many of James Tool’s customers.

James Tool currently serves many industrial clients, primarily the aerospace and the automotive industry. 3D printing not only gives their existing customer base a new option for tooling and manufacturing new products and parts, but it allows smaller companies who may have not been able to previously afford their services access to their expertise.

With stories like this continuing to emerge, 3D printing likewise continues to shake its image as an overhyped curiosity and is becoming established as a necessary service to offer for any manufacturing company. James Tool — like many other companies — is waking up to the fact that 3D printing isn’t going anywhere any time soon, and if they want to stay relevant in the modern industrial manufacturing field then 3D printing services are a vital component in their portfolios.