ECN, a Netherlands based research institute, will showcase a new metal 3D printing technology at formnext 2017.

ECN says Direct Multi Metal Printing is combination of a powder bed approach and a new process. Adding this new process to conventional Powder Bed Fusion (PBF) has several advantages ECN tell us.

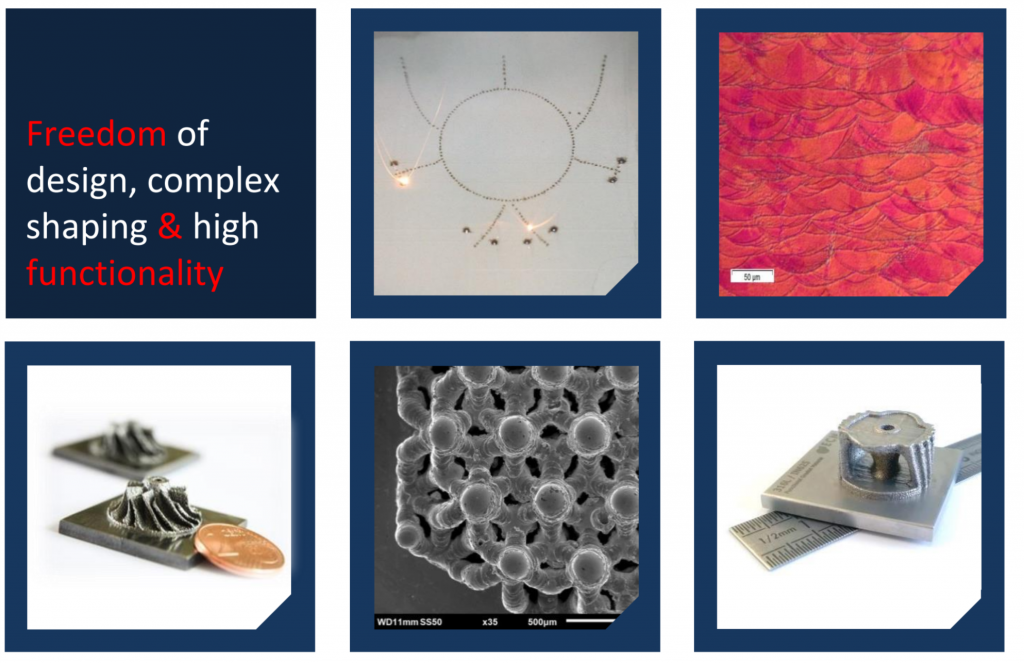

These include a “low internal stress build-up during densification, resulting in low residual stress and improved resolution” and “homogenous microstructure, resulting in high quality material properties without annealing.”

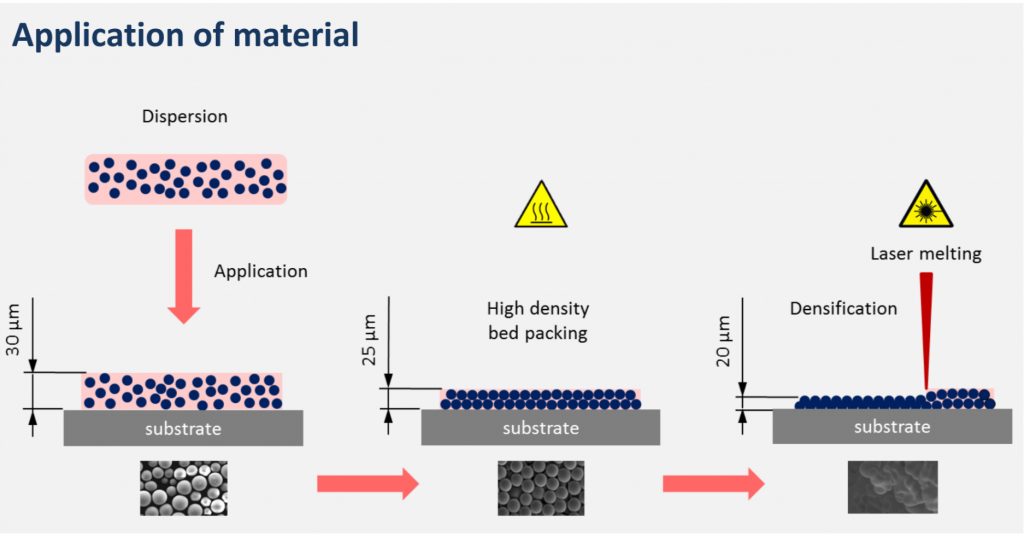

Direct Multi Metal 3D Printing involves several stages, starting with dispersion based application of metal powders. Metal powder is applied using a multi dispensing system and followed by densification of the added layer. This process results in a highly dense well packed print bed, to which the laser can then process. The stages are then repeated in a similar manner to PBF.

No additional sintering or annealing steps required

ECN says their technology is particularly focused on providing opportunities to high-tech the automotive, aerospace and medical sector.

The Energy research Centre of the Netherlands (ECN) is the largest energy research institute in the Netherlands and have worked with Admatec in the past to commercialise research. In March, Admatec and ECN launched another metal 3D printer, the ADMETALFLEX. The new metal 3D printer will be on display during formnext at the Admatec stand.

According to ECN the LASERFLEX Conflux ”upgrades the Powder Bed Fusion (PBF) process to provide higher material quality and finer features and enables handling of multiple materials and functional grading, while maintaining the advantages of a direct product generation process without additional sintering or annealing steps.”

Pricing has not yet been announced on the LASERFLEX Conflux.

Technical Specifications

Printing technology Dispersed Metal Powder Bed Fusion²

Build volume Platform 100 mm x 100 mm x 100 mm

Platform ø 100 mm x 100 mm

Layer thickness 10 – 100 µm

Focus diameter 50 µm typical

Laser type Yb fiber laser 200 – 400W CW

Scanning speed Up to 9 m/s

Materials Stainless Steel 316L Inconel 625 Other materials under development

Atmosphere Shielding gas – Nitrogen

Recoating system Multi – Dispense system

Filtration H13 – Cat. BIA-C

For all the latest 3D printing news, subscribe the most widely read newsletter in the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.