The Fraunhofer Institute for Laser Technology (ILT) and German prototyping specialist Rapid Shape GmbH have co-developed a new light based 3D printing technique. Challenging one of the main necessities of other 3D printers, the “TwoCure” process eliminates the need for typical support structures, making post processing parts easier than ever before.

Free-floating 3D prints

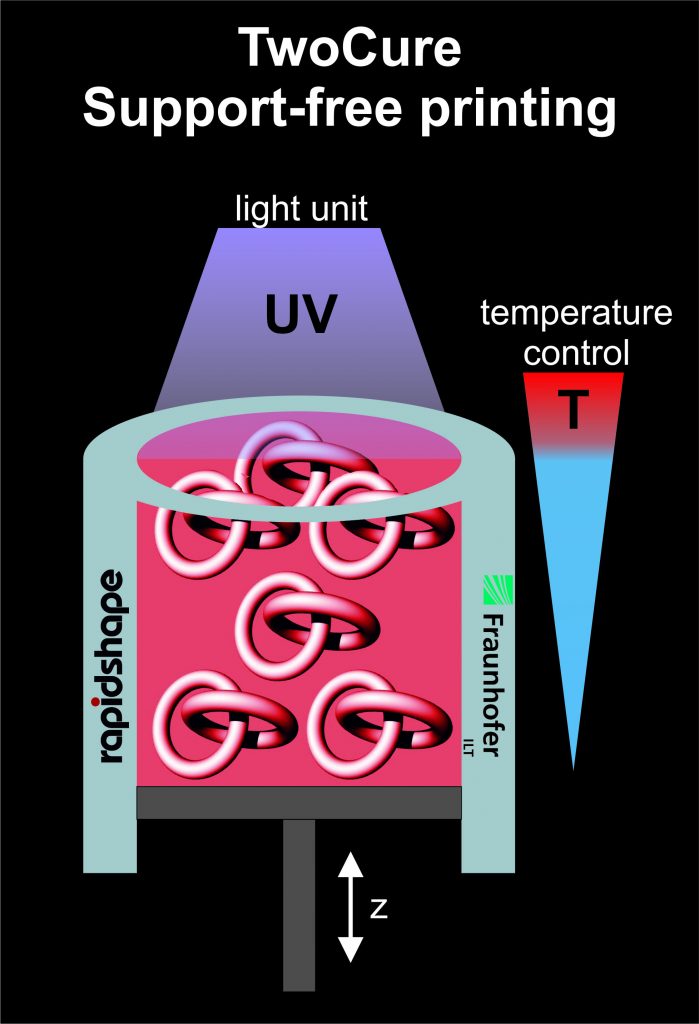

As the name suggests, the TwoCure technique is essentially a two step curing process, harnessing both light and thermal energy to cure a resin material. A part is made in much the same way as it is in typical SLA – built up in consecutive layers as the liquid material hardens on exposure to light. The main difference is that the resin in this case is applied warm, and then cooled within the build area.

Holger Leonards, project leader at Fraunhofer ILT, explains the process as follows, “The material is applied warm and then irreversibly cured by light. At the same time the cooled installation space ensures that the thermoset component being created layer by layer freezes to form a block with the resin that has solidified like wax.”

Encased in a house of wax

The wax-like block around the 3D printed parts acts in a similar way to the powder cake created in sintering machines, allowing multiple objects to be packed on top of each other inside a single print chamber.

The block liquefies at room temperature for easy removal, requiring little cleaning and final post cure to finish the part.

In the future Fraunhofer ILT and Rapid Shape researchers hope to fully automate the TwoCure process so cleaning and the post curing is taken care of in a single end-to-end operation.

Coming soon

As free-floating 3D prints, items made in the TwoCure process are also disconnected from the build platform, rendering chisels and flexible build plates irrelevant. At present, the Fraunhofer/Rapid Shape team has made its first TwoCure prototype 3D printer which may be ready for series in the near future.

A further preview of the technology will be exhibited at formnext 2017 in Frankfurt. For 3D Printing Industry’s liver coverage of the event, sign up to our free newsletter, follow us on Twitter and like us on Facebook.

Featured image shows interlocking rings 3D printed in the TwoCure SLA process. Photo via Fraunhofer ILT