Finnish alternative energy and material company UPM, and its subsidiary UPM Biocomposites have demonstrated the potential of large-scale 3D printing. In partnership with robotics manufacturer ABB and FFF 3D printer manufacturer Prenta Oy, UPM has created large components and furniture using its recyclable UPM Formi 3D feedstock.

Eve Saarikoski, Applications Manager at UPM Biocomposites, comments, “Together with our partners, we are exploring the new possibilities in the fileld of large scale 3D printing. Large scale 3D printing technology is fast evolving and we are part of the evolution with our biocomposite technology offering new woodbased materials for the markets.”

In addition, the company announced that it would be working on a new cellulose-nanodiamond 3D printable material, with nanodiamond additive supplier Carbodeon.

Saarikoski adds, “Our aim is to bring sustainable biocomposite alternative to the field of technical polymers with short fibre filling.”

Large scale 3D printing with PrentaRobo

Headquartered in Helsinki and founded in 1996, UPM is a company promoting and supporting sustainability in the forest industry. It produces pulp, paper, plywood, bioenergy, biofuels, biochemicals and other wood-derived bioproducts.

For 3D printing, the company has its range of UPM Formi 3D materials, which come in both granulated and filament form. UPM Formi 3D materials are made from a combination of cellulose fibers and PLA. They are FSC® and PEFC™ certified, deeming them responsible forested and a verified advanced recycled raw material.

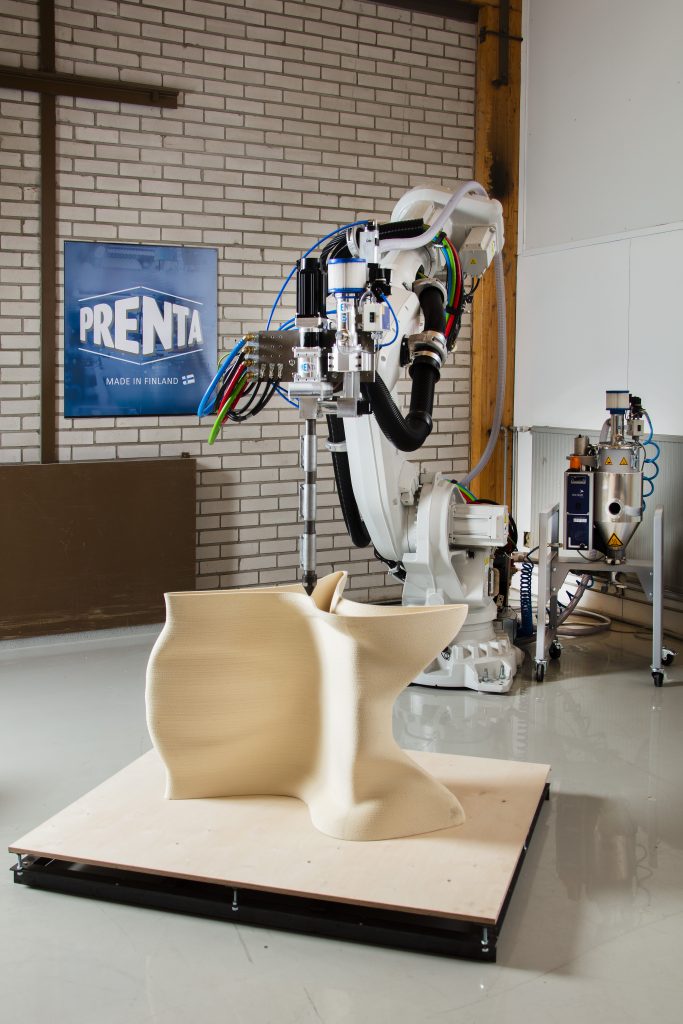

In UPM’s recent large scale projects, granulate UPM Formi 3D was used to create large scale, recyclable components using Prenta Oy’s PrentaRobo. Pasi Kukkonen, Product Manager of ABB Oy Robotics, explains, “This is a pioneering technological innovation that represents the next level in large scale industrial 3D printing. We’ve made possible to use an extrusion head in our IRB6700 6-axis robot to create a 3D printing system that’s ideal for very precise and large scale additive manufacturing.”

“External axes and trackmotion have been added to achieve an even bigger working area. Users can then control the extrusion head and create printing paths with our 3D simulation program RobotStudio, the industry’s leading PC-based solution for offline programming, configuration and virtual commissioning.”

Stronger sustainable materials

In partnership with Carbodeon, UPM is enhancing its UPM Formi 3D materials for stiffness, strength and higher heat deflection. PLA-based, these materials will be reinforced with cellulose and nanodiamond content.

“By combining nanodiamond and cellulose fibre technologies together we can have natural fibre composite that has higher melt flow than of standard plastics,” says Saarikoski.

Previously, Carbodeon worked with VTT Finland to develop the nanodiamond-reinforced uDiamond filament.

Vesa Myllymäki, CEO of Carbodeon, concludes, “Product development partnerships with innovative companies like UPM are a key part of Carbodeon’s global growth strategy.”

Vote now for your Material Company of the Year in the 2019 3D Printing Industry Awards. For all of the latest 3D printing materials news and releases, subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Featured image shows large-scale 3D prints made for metal casting. Photo via UPM