3DGence, a Polish 3D printer manufacturer, has expanded the capabilities of the INDUSTRY F340 3D printer with a new High Flow (HF) printing module.

As the fourth module compatible with the INDUSTRY F340, this accessory is the first to be equipped with nozzles of a 0.6 mm diameter, enabling large prints at a faster production rate. Filip Turzyński, Quality Development Manager at 3DGence, said:

“We decided to introduce a new module with 0.6 mm nozzles because it will allow us to produce details from ABS in a much shorter time than before. On some geometries, we get up to 40% shortening of the print time.”

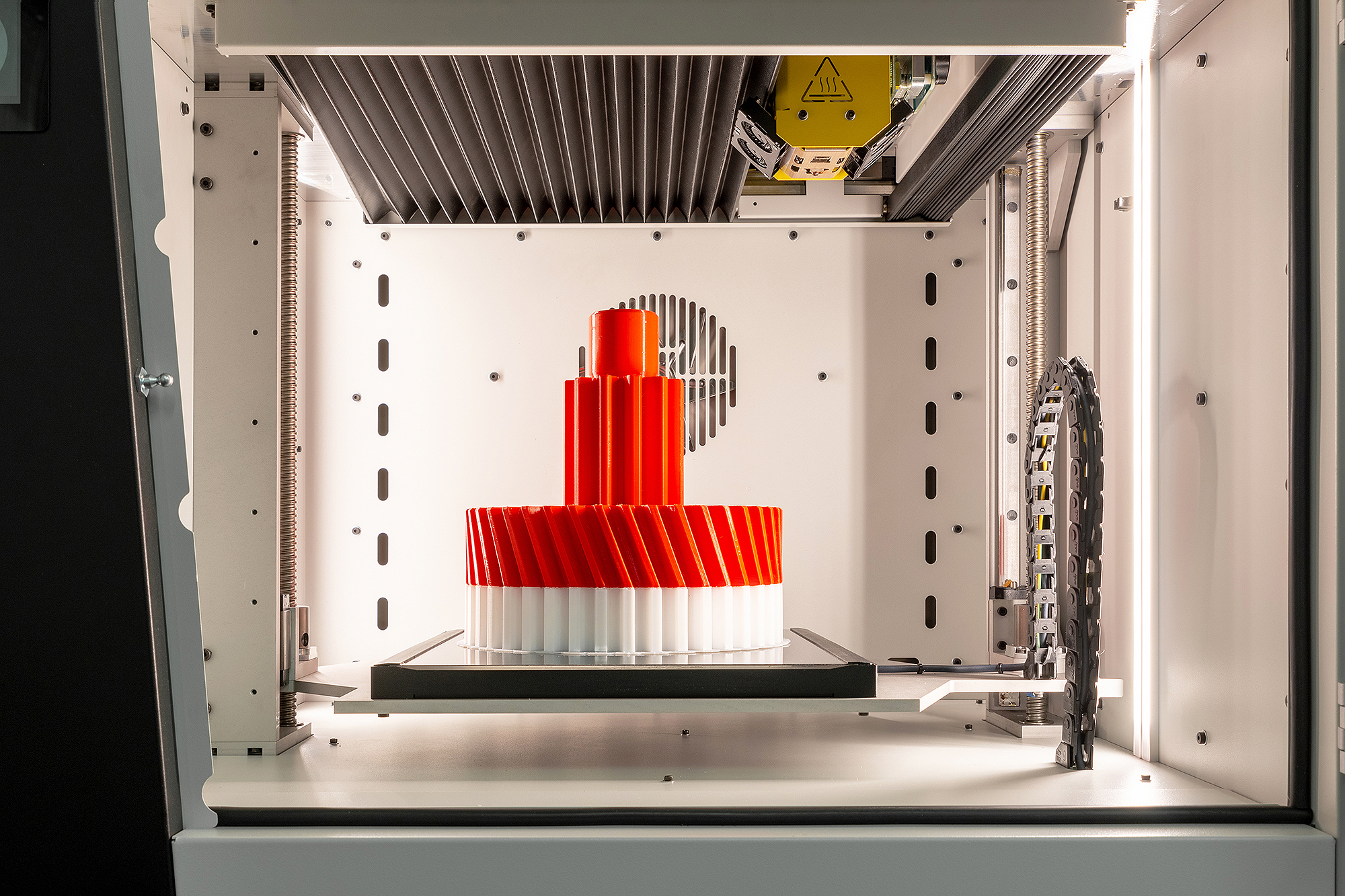

The 3DGence INDUSTRY F340

Introduced last year, the INDUSTRY F340 is an FFF/FDM 3D printer aimed towards applications from production to prototyping in a variety of industrial workplaces. As a result of its interchangeable HF modules, the F340 is able to process high-grade thermoplastics such as PEEK.

With a print temperature ranging from 190°C – 265°C, the fourth module will accommodate 3DGence’s latest reinforced materials, PA-CF and PA-GF (Glass-Filled Polyamide). “The HF module was implemented to meet the customer needs which are increasing applications of carbon fiber or glass reinforced materials in their work,” added Mikołaj Skorupa, 3D Printing Application Engineer at 3DGence.

“Parts manufactured with PA-CF and PA-GF are characterized by increased thermal resistance, but also the hardness and durability. These plastics are commonly used in industrial injection processes.”

High flow 3D printing

Dominik Fitowski, Export Manager at 3DGence, explained, “There are a lot of 3D printers on the market today, which are compatible with a very narrow range of materials, it is associated with the need to have several different devices.”

“3DGence INDUSTRY F340 is the exception in the industrial 3D printers segment. It has been equipped with a modular system, which is a more practical and more cost-effective solution. To print from a wide range of materials you do not need to buy a new machine, just replace the module. Customers can choose the ideal device to suit their needs, they can upgrade it and add other printing modules.”

Recently, the company released the Engineering Soluble Material (ESM-10), a soluble support material for PEEK and ABS. Presently, 3DGence are working to expand the base of available materials for the new HF module, which involves testing of other reinforced materials from manufacturers such as DuPont, Clariant, and Owens Corning.

The PA-GF material from 3DGence will be implemented in mid-April.

Vote now to decide this year’s winners of the 2019 3D Printing Industry Awards.

For all of the latest additive manufacturing news and updates, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Featured image shows all the modules of the 3DGence INDUSTRY F340. Photo via 3DGence.