Research led by Seung Kwon Seol at the Korea Electrotechnology Research Institute (KERI) proposes a 3D printing method devised for the manipulation of silver-laden nanoparticle inks. The method enables the 3D fabrication of nanoscopic silver objects that, according to Seol, “would enhance the versatility of 3D printing in the making of various components needed for future wearables.”

3D printing electronics for bionic skin and smart fabrics

Due to the design flexibility possible with 3D printing, the method is achieving significant recognition for its application to electronics, as in Nano Dimension’s DragonFly 2020 printer, and Optomec’s Aerosol Jet technology. Leading the way for the future of wearable technology, 3D printed electronics are found in the development of smart fabrics that can read conditions of the human body, or sensors that could be embedded to give people bionic fingertips.

With high electrically conductive properties, silver is often the key ingredient of such research. And so the KERI study, completed with partners at the Korea University of Science and Technology, Hanyang University and The University of Hong Kong, proposes a method of created 3D silver structures that makes the most of the material’s unique properties.

A guiding, liquid-ink meniscus

In the KERI method, a liquid-ink meniscus is used to guide silver particles as they are 3D printed in layers. The advantage of depositing the material through a meniscus allows for the positive flow of the material, and improved control of its deposition. Without it, it would be harder to achieve complex geometries in the 3D printed silver.

The ink is composed of an polyacrylic acid laced with silver nanoparticles. When extruded the acrylic content evaporates, leading to the rapid solidification of the silver in subsequent layers.

3D printing of the silver nanaoparticle ink. Clip via supplementary materials ACS Applied Materials & Interfaces.

The silver microstructures are also heat-treated using microwaves after 3D printing to improve structural integrity through sintering.

Functional structures invisible to the naked eye

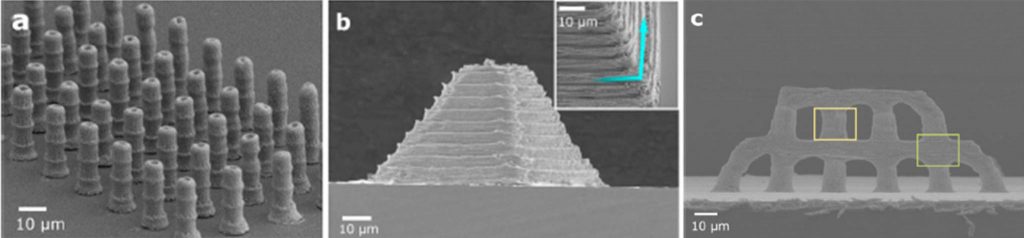

To test structural ability of the method, researchers 3D printed the ink into a number of microscopic designs. The 3D printed micro-pyramid seen in the image below (b) measures just 45μm in height which is equal to the approximate width of a single human hair.

The method was also used to create a freestanding array of pillars (a), and a ‘coliseum-like architecture’ (c) that demonstrates its ability to work both horizontally and vertically.

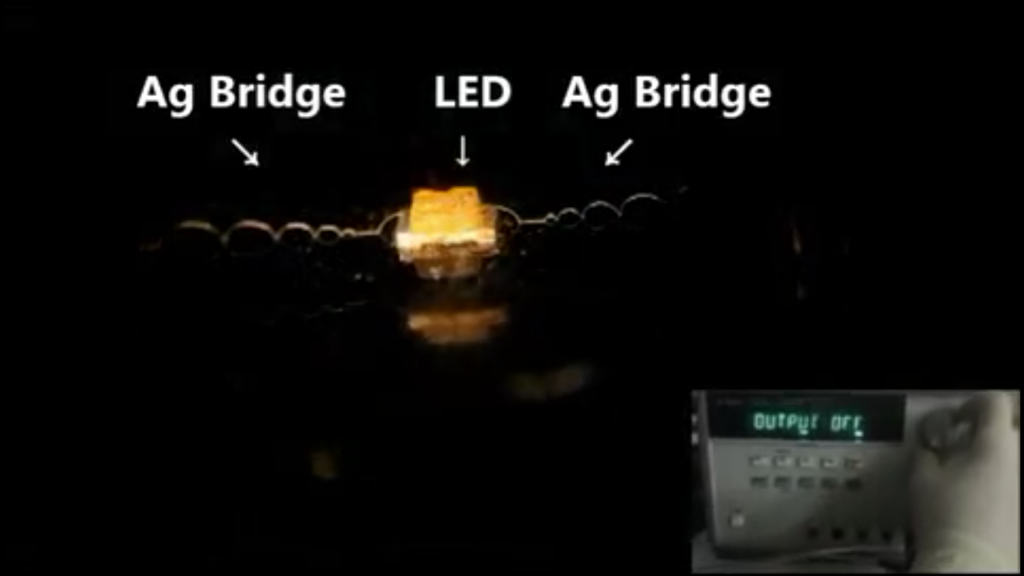

Electrical conductivity was then tested by incorporating a miniature LED light into a silver bridge design, that lights up and fades when controlled using an external box.

The nano advancement of additive manufacturing

Overall findings show “a simple and inexpensive way to produce freestanding Ag microarchitectures via meniscus-guided 3D printing”. Next steps for the study are already underway as researchers look to develop multi-material capabilities on a nanoscale. Authors also stipulate that inks incorporating functional quantum dots (semi-conducting nanoparticles) are also in development, with the potential to “lead to important advancements in additive manufacturing.”

Inspired by the natural formation of desert roses, created from sand with fog from the sea, researchers at Washington State University also propose an alternative approach to 3D printing with silver nanoparticle inks. Using multiphotonic lithography as opposed to a deposition method, TU Wien researchers successfully 3D printed a geometrically complex castle onto the tip of a pencil.

Three-dimensional Printing of Silver Microarchitectures Using Newtonian Nanoparticle Inks discussed int his article is published online in ACS Applied Materials & Interfaces. It is co-authored by Sanghyeon Lee, Jung Hyun Kim, Muhammad Wajahat, Hwakyung Jeong, Won Suk Chang, Sung Ho Cho, Ji Tae Kim, and Seung Kwon Seol.

Stay up-to-date with the latest 3D printing research and news by subscribing to our newsletter and following us on twitter and Facebook.

Featured image: Cropped illustration demonstrating the 3D printing process of silver nanoparticles inks. Image via ACS Applied Materials & Interfaces