Engineers at Taylor University have developed a 3D printer that’s said to be capable of constructing extraterrestrial bases far more quickly than current systems allow.

Unlike other proposed off-world habitat-building platforms, which are restricted to single-site production, the team’s ‘Mobile Gantry’ is mounted on wheels, enabling it to traverse planetary surfaces and print on-demand. Thanks to this flexibility and the machine’s ‘gantry without rails’ layout, its creators say it could allow for the “sequential building” of Martian bases, with areas that open as they’re ready.

Preparing for Martian colonization

In recent years, space agencies and contractors around the world have begun to accelerate their preparations for new exploratory missions. These don’t just include the likes of NASA’s Artemis program, which aims to return humankind to the Moon by 2025, but plans to send orbiters and landers to the red planet, being organized by agencies based in the US, China, Russia, Japan and India, amongst others.

One of the many issues that has arisen around future extraterrestrial missions, is how best to establish permanent, habitable bases in the cold vacuum of space. If facilities were to be built on terra firma and fired to lunar or Martian landing sites, they would be astronomically expensive to launch, as well as being restrictive to settler population growth.

Similarly, using traditional manufacturing methods to build on planetary surfaces would be made difficult by numerous factors, not least the shipping of construction materials, thus 3D printing has gained traction as an alternative. Theoretically, at least, it’s possible to process resources like lunar regolith via the technology, plus its inherent flexibility allows for the realization of unique, modular structures.

However, the team highlights how existing ‘Fixed Base Radial Arm’ systems are hamstrung by both their limited reach, and inability to move between locations until builds are finished. Mobile robotic and gantry-based approaches have also shown promise as extraterrestrial construction mechanisms, but the engineers say the methods “constrain habitat design” and “possess limited speed” respectively.

Introducing the ‘Mobile Gantry’

To get around the limitations of current construction 3D printing approaches, the Taylor University team has effectively decided to combine the technology behind mobile and gantry units into a single system. In practice, this means their machine is able to create an X-axis by rolling along, before using prismatic joints as a means of achieving Y and Z-axis motion, and ultimately print without relying on rails.

In order to ensure that the Mobile Gantry doesn’t cause errors by running off-course, the engineers have also fitted it with a ‘local positioning system,’ enabling it to determine the position, orientation and velocity of its printhead. This, the engineers theorize, will allow the machine to operate wirelessly, rapidly update and create quality structures with precision, all while taking surface bumps in its stride.

Already, the researchers have managed to realize their concept in the shape of a prototype, complete with terrain compensation, fine positioning and 3D printing subsystems. During initial testing, this ‘Mud Dauber’ design has proven capable of traversing uneven terrain and using a Cartesian positioning system with three degrees of freedom, to extrude a slurry of sulfur concrete into complex structures.

With further R&D, the engineers believe that Mobile Gantry systems have the potential to enable the “parallel construction” of sites “with vast internal volumes” and tapered junctions that allow for their expansion. Given the size and simplicity of their design, the team also anticipate that in future, their bot can be deployed in packs, as a way of “completing prints much faster with a higher quality.”

Advances in lunar 3D printing

Lunar regolith-based 3D printing approaches continue to gain momentum as a means of building resilient, habitable infrastructure for settlers on the Moon. Just last year, it was revealed that the University of New South Wales had been drafted in to help Luyten develop its Platypus Galacticas 3D printer, a 9m x 12m gantry-mounted system designed to aid Australia’s bid for a permanent lunar presence.

Netherlands-based firm MX3D, meanwhile, has come up with a skeletal 3D printed lunar floor concept for a prototype European Space Agency Moon settlement. Using additive manufacturing, the company has been able to realize its smooth, web-like design while producing it from lightweight steel, and at the time, it was said to be possible to embed functional monitoring systems into the structure.

Elsewhere, at a more experimental level, scientists from the Technical University of Braunschweig and Laser Zentrum Hannover have also developed a lunar rover with 3D printing capabilities. As part of their project, codenamed ‘MOONRISE,’ the researchers have already managed to mount a laser to a ‘MIRA3D’ vehicle, before utilizing it to melt moondust into large, spherical prototype structures.

The researchers’ findings are detailed in their paper titled “The Mobile Gantry: A Robotic Architecture for 3D Printing Structures on Mars,” which was co-authored by Peter Staritz, Caleb Miller and Josiah McClurg.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

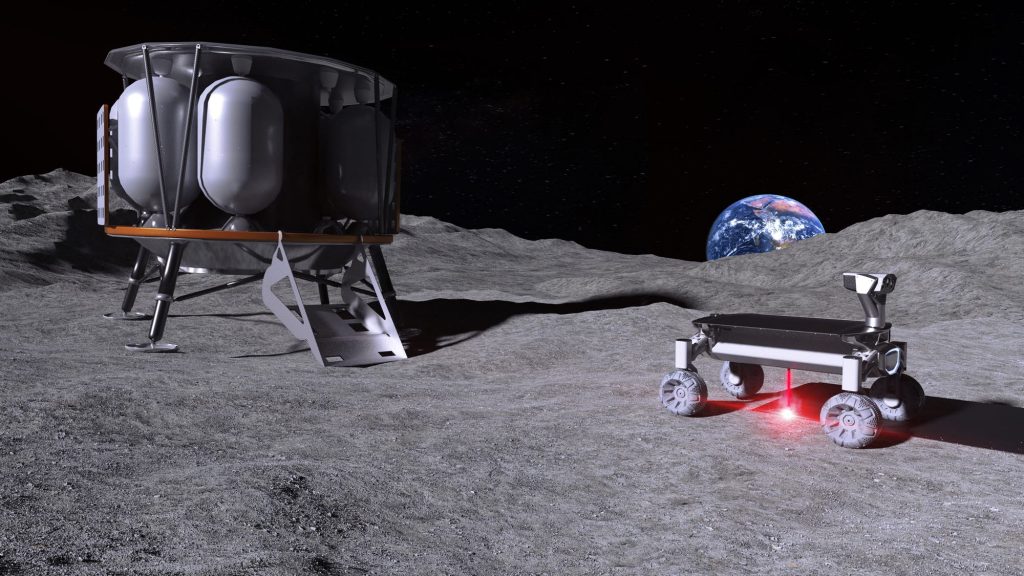

Featured image shows the engineers’ ‘Mud Dauber’ Mobile Gantry 3D printer prototype. Image via Taylor University.