Scientists from the Technical University of Braunschweig and Laser Zentrum Hannover (LZH) have 3D printed lunar regolith under zero gravity for the first time.

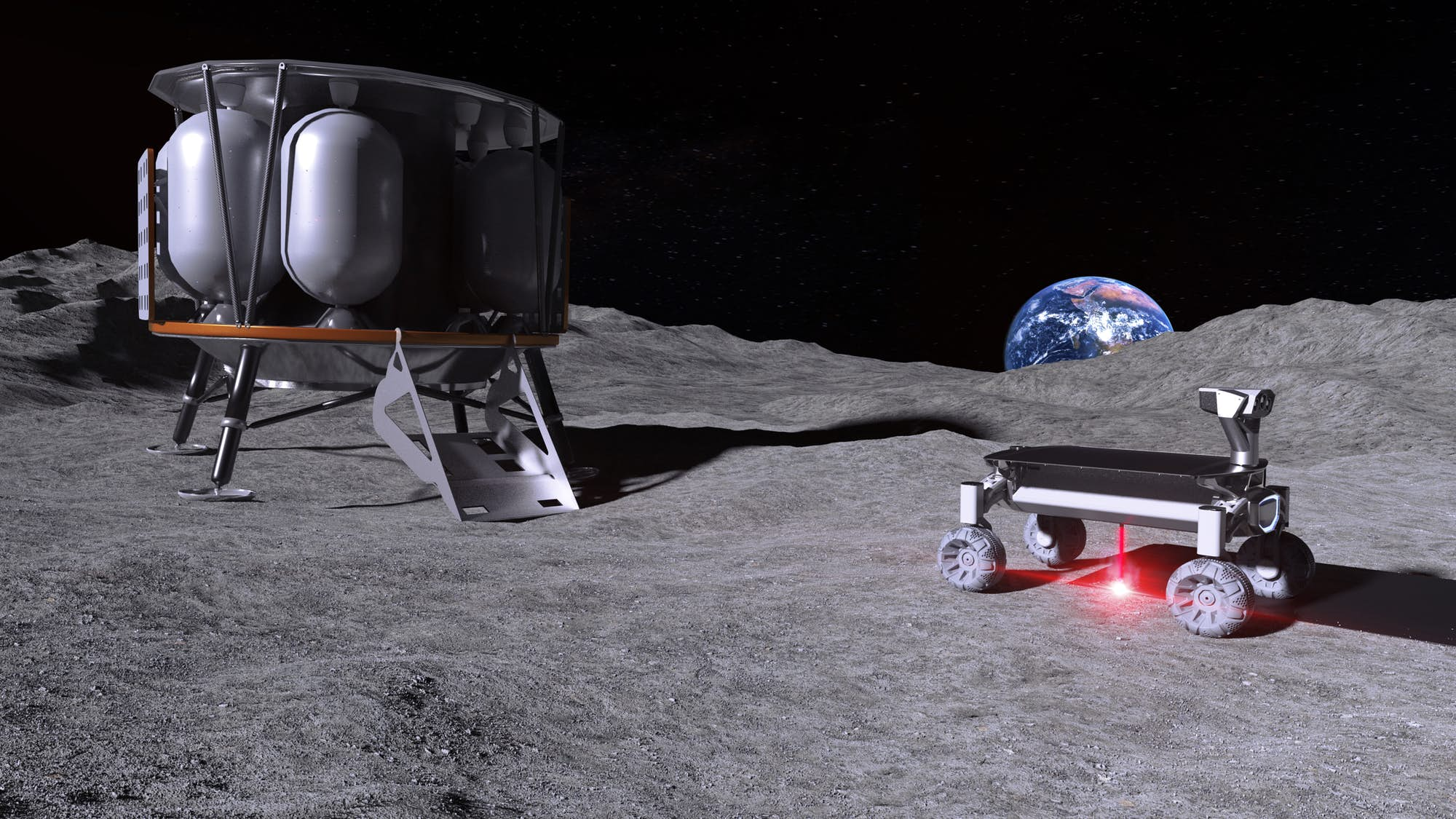

During their experimental ‘MOONRISE’ project, the team mounted a customized laser to their ‘MIRA3D’ lunar rover and melted moondust into spherical shapes. With further R&D, the laser’s head could form the basis of a flight-ready model, that enables future astronauts to create economical long-term structures on the Moon.

“We were able to precisely control the laser’s head on the arm of the rover, thus melting larger structures with complete success,” said TU Braunschweig’s Professor Enrico Stoll. “Together with experiments conducted in LUH’s ‘Einstein Elevator,’ we have a solid basis for 3D printing with the laser on the Moon.”

The scientists’ dust-melting mission

Project MOONRISE was initiated in 2019 by LZH and TU Braunschweig’s Institute of Space Systems (IRAS), with the aim of reducing the cost of firing payloads into Lower Earth Orbit (LEO). Given that launching gear into LEO can cost up to $100,000 per kilo, lowering cargo weight has become vital for many aerospace firms.

This prompted the German-based team to develop a system that’s capable of printing durable structures on the Moon using only lunar regolith, thus removing the need to transport them at all. The team’s Volkswagen Foundation-funded research program centers on their novel ‘MOONRISE’ laser, which weighs less than 3kg.

According to LZH scientist Niklas Gerdes, the device’s small size hasn’t affected its resiliency, and it has now passed a series of temperature and vibration tests. “In the last two years, we have developed a laser head that is only about the size of a large juice box,” said Gerdes, “yet it can withstand the adverse conditions of space.”

One small step for 3D printing…

As the two-year project is coming towards its conclusion, the team has recently sought to conduct more advanced experiments with their laser. For instance, using Leibniz University Hannover (LUH’s) ‘Einstein-Elevator,’ the scientists have been able to fabricate complex structures under realistic Moon-like conditions.

Not only did these tests represent the elevator’s inaugural experiments, but they yielded novel spherical objects, a fact that thrilled LZH Professor Ludger Overmeyer. “In the elevator, we succeeded in melting regolith into spheres – both under complete weightlessness and lunar gravity,” he said. “That is unique in the world!”

To assess their laser’s end-use capabilities, the team then strapped it onto IRAS’ MIRA3D rover, a lunar vehicle that’s specifically designed to enable space-based 3D printing. Using the buggy’s platform and robotic arm, the scientists found that they were able to precisely fabricate objects into pre-ordained regolith designs.

Following their device’s initial success, the researchers have begun to negotiate with space agencies, as they aim to develop the laser into a flight-ready model. If given the chance to complete their work, the scientists claim that their novel device could be utilized to fabricate robust futuristic settlements on the Moon.

Fabricating zero-gravity structures

As the Chinese, Russian and U.S. national space agencies continue to seek a permanent presence on the Moon, they are increasingly turning to 3D printing as a cost-effective construction tool.

Texas-based construction company ICON has gained a contract from NASA tasking it with the development of a full-scale prototype off-world 3D printer. As part of the project, which is codenamed ‘Olympus,’ the firm has created a division that’s dedicated to fabricating space-faring structures using only lunar regolith.

Russian space agency Roscosmos has also confirmed plans to support long-term missions by 3D printing structures made from on-site material. Although the exact details of the project remain unclear, the cosmonauts are set to land on the Moon in 2027, three years after NASA’s Project Artemis astronauts are scheduled to do so.

Unsurprisingly, China’s National Space Administration (CNSA) has revealed plans to 3D print a base on the Moon as well. The CNSA’s R&D project potentially hinges on the success of its Chang’e 5 mission, which if successful, would become the first probe to return lunar samples to Earth since the 1970s.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D rendering of the laser 3D printer designed by LZH and IRAS. Image via LZH.