3D printing with pellet extrusion or hybrid technology is appealing for larger format applications such as sand casting patterns or thermoforming molds. I spoke with Clay Guillory, Director – Titan, 3D Systems, and Rahul Kasat, Vice President at 3D Systems, to learn more.

Titan was initially founded by Guillory in 2014 and acquired by 3D Systems in April 2022. Guillory highlighted the organic growth that Titan experienced, from building “Open air filament machines” to the pivotal shift towards “industrial quality machines with heated chambers.” Their brainchild, the pellet extrusion machine, marked a notable milestone, significantly ramping up print speeds and broadening material selections, which Guillory described as feeling “almost limitless.”

Rahul Kasat, who joined the Titan team as a business partner in 2018, emphasized the strategic pivot in the same year towards exclusively focusing on the industrial segment. A key part of this strategy was emphasizing “pellet extrusion technology development,” which paved the way for hybrid platforms merging filament and pellet extrusion technologies. The innovative streak continued with the launch of machines boasting multiple extruders and, later, a platform harmonizing additive and subtractive technology.

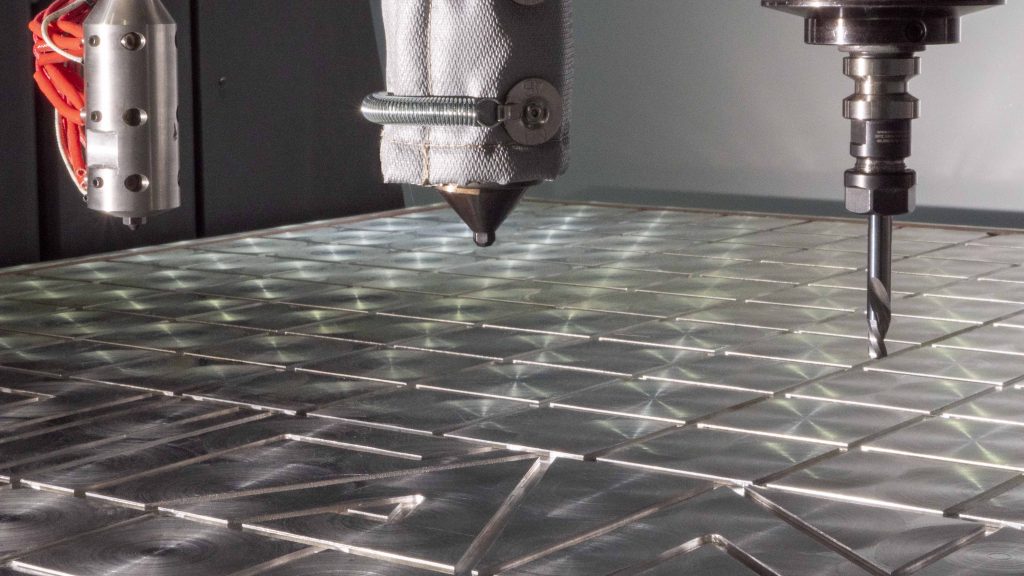

These technical advances culminated in a novel platform that intertwined additive and subtractive technology, achieving “high print speed and better surface finish.”

Reflecting on the successful trajectory, Kasat noted how their continuous innovation in pellet extrusion technology made them a “preferred partner for several industrial customers,” leading to a thriving business that saw doubling growth year over year. This success caught the attention of 3D Systems, culminating in the acquisition of Titan Robotics.

Read more in the 3D Printing Industry Executive Interview series.

Pellet Extrusion 3D Printing: Bridging Traditional and Modern Manufacturing

Rahul Kasat elaborates on the initial hesitance surrounding new technologies, pointing out that “the first step of the process is skepticism.” The fears of investment stem from an uncertainty about the technology’s maturity and evolving nature. Titan Robotics took the mantle to demystify pellet extrusion technology, developing applications that have now found ground in sand casting and thermoforming sectors, which previously faced challenges due to size and material cost constraints.

Clay Guillory illuminates the cost-effectiveness of pellet extrusion in contrast to traditional manufacturing methods, remarking how it brings “the cost down to the point where we can either displace or kind of complement traditional methods.” This technology fast-tracks the prototyping and production tooling processes, significantly cutting the lead time from “four or five weeks of work” to a much shorter timeframe. Guillory further notes that this innovation also “enables better parts” due to its inherent design flexibilities.

Discussing the market dimensions, Kasat mentions that while the thermoforming market spans billions of dollars across automotive, aerospace, and consumer goods sectors, their focus is on the tooling part of the process. This focus accelerates design approvals and initial production runs before transitioning to more expensive, traditional tooling methods for mass production. Though hesitant to pin a precise number on the market size for sand casting and thermoforming tooling, Kasat estimates a vast scope with around “5000 foundries and pattern shops” globally, indicating that the adoption of pellet extrusion technology is merely “scratching the surface.”

Vote now in the 2023 3D Printing Industry Awards.

Pellet Extrusion 3D Printing: A Catalyst for Manufacturing Efficiency and Material Flexibility

There is a burgeoning influence of pellet extrusion 3D printing in addressing common manufacturing pain points, particularly in time and labor efficiency, material storage, and flexibility.

Guillory highlighted the role of pellet extrusion in creating “jigs and fixtures,” reducing waste, and accelerating the manufacturing process. The technology is a game changer in sheet metal manufacturing, where complex assemblies can now be printed as one piece in a few hours. The aerospace sector, too, is reaping benefits, with one major manufacturer leveraging this technology for F-35 and F-16 flight simulator production. Guillory notes that a complex assembly with hundreds of parts was condensed to three large pieces, printed and post-processed, marking a significant cost and time saving, though specific figures were withheld.

Material flexibility is another frontier where pellet extrusion shines. Unlike traditional 3D printing constrained to specific materials like PLA or ABS, pellet extrusion opens the door to many materials, including carbon fiber-filled and high-temperature materials. Kasat emphasized, “They can select the material of their choice for end functionality,” thus expanding the realm of applications in traditional manufacturing that were previously unreachable by 3D printing.

Kasat delved into macroeconomic trends, underscoring the labor shortage in traditional sectors like sand casting. He remarked, “3D printing will disrupt that industry, where a labor shortage is emerging.” The technology also addresses storage issues for sand casting and thermoforming sectors, where physical patterns must be stored for future use. With 3D printing, they can now “destroy it and reprint this pattern when needed,” reducing the need for storage space and climate-controlled environments.

Guillory elaborates on the ability of this technology to significantly reduce the labor and time involved in crafting complex assemblies traditionally done through laser cutting, bending, and welding operations. Guillory remarks, “We can now use materials that check all those boxes for strength and stability and long-term durability,” which was not feasible with conventional materials like PLA and ABS.

The discussion then veers towards the market reaction to “disruptive.” Rahul Kasat clarifies the stance of 3D Systems, stating that the term is employed more in a complimentary sense rather than a destructive one. He notes, “You’re using the word disruptive to either gain more efficiency or get things done faster than they have been done before.” The essence of disruption here leans towards aiding manufacturers in speeding up processes, like tooling, which traditionally could take six to eight weeks but now can be expedited to an overnight operation thanks to 3D printing.

Kasat further advocates for viewing 3D printing as a “complementary technology to traditional manufacturing” rather than a competing one. This perspective, he argues, facilitates a smoother understanding and adoption of 3D printing technology within traditional manufacturing realms, thereby progressively making it a mainstream technology for manufacturers.

Large Format 3D Printing: Emerging Trends

As the domain of large-format 3D printing evolves, Rahul Kasat and Clay Guillory gave an insight into the forthcoming trends. A significant emphasis is placed on the advent of “more engineering and functional materials” to facilitate the production of parts and a move towards sustainability through “closed loop recycling of 3D printed parts,” as per Kasat.

Further advancements are eyed in achieving “better speeds” and “higher quality parts” to enhance throughput. Guillory sheds light on the trend of in-situ monitoring, which is geared towards refining the print process in real-time, thereby reducing human error and enabling a more “lights out production” scenario. This entails employing sensors and controls within the printing machines to monitor and adjust the print process, ensuring better, validated outputs straight from the machine without secondary qualification processes.

Material development is also on the horizon to bolster sustainability alongside augmenting the build strength of materials. Guillory mentions that there are exciting prospects in this sphere, hinting at a foreseeable future where material innovation intersects with real-time print monitoring to push the envelope of large-format 3D printing.

Advancing Closed-Loop Recycling in Large Format 3D Printing

Kasat and Guillory explored the prospects and challenges surrounding closed-loop recycling in large-format 3D printing. As Kasat explains, the concept involves “taking these 3D printed parts, breaking them down into the feedstock” to be reused, thus embodying a sustainable approach in handling post-use 3D printed parts. Given the substantial size of these parts, which could weigh around “100 pounds or 200 pounds,” the significance of a recycling pathway is underscored.

Pellet extrusion technology is a pivotal driver for fostering innovation in closed-loop recycling. According to Kasat, this technique stands out as it could break down used parts into pellets, which can then be remelted and reprinted into new or other parts. However, the journey towards a robust closed-loop recycling system still needs to improve, particularly around who will take on the responsibility of collecting and converting these parts back into feedstock.

Delving into the practical aspect, Guillory mentions that they, along with partners, have indeed “printed parts with recycled materials,” indicating a step forward in proving the concept. Yet, the venture is in its nascent stages, awaiting broader engagement from material companies and other stakeholders in the 3D printing ecosystem.

Staying Ahead in the Fast-Evolving 3D Printing Landscape

A prime aspect of maintaining a competitive edge, as explained by Kasat, revolves around actively “listen[ing] to your customers” to fathom their evolving requirements, which ultimately informs their product roadmap. He illustrates this by integrating a spindle with pellet extrusion, prompted by customer feedback, which significantly enhanced surface finishing and gained notable traction post-launch.

Guillory emphasizes the global footprint facilitated by 3D Systems, underscoring the ability to provide real-time support “all over the planet” as a key factor in staying ahead. The global outreach, equipped with Technology Centres offering assistance in native languages, not only edges out the competition but ensures a seamless adoption of their technology across diverse regions, including India, Australia, and Japan.

The dialogue reflects a blend of customer-centric innovation and global expansion as core strategies employed by 3D Systems to navigate the dynamic 3D printing industry, with a collaborative effort to continually evaluate market potentials.

Follow the full coverage of Formnext 2023 here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D Systems EXT 1070 Titan Pellet. Photo by Michael Petch.