Xometry, a pioneering marketplace in the manufacturing domain, was conceived out of an enthusiasm for 3D printing’s potential to revamp supply chains by co-founders Randy Altschuler and Laurence Zuriff in 2013. The duo delved into the world of 3D printing, engaging with both manufacturers and customers, only to discover a broader horizon than initially envisaged. They realized that 3D printing was just a fragment of an expansive opportunity that lay in digitizing the procurement process in manufacturing, transcending geographical and sectoral boundaries that traditionally confined small manufacturers.

I spoke with Randy Altschuler, CEO and co-founder of Xometry Inc. to learn about the company’s ascent.

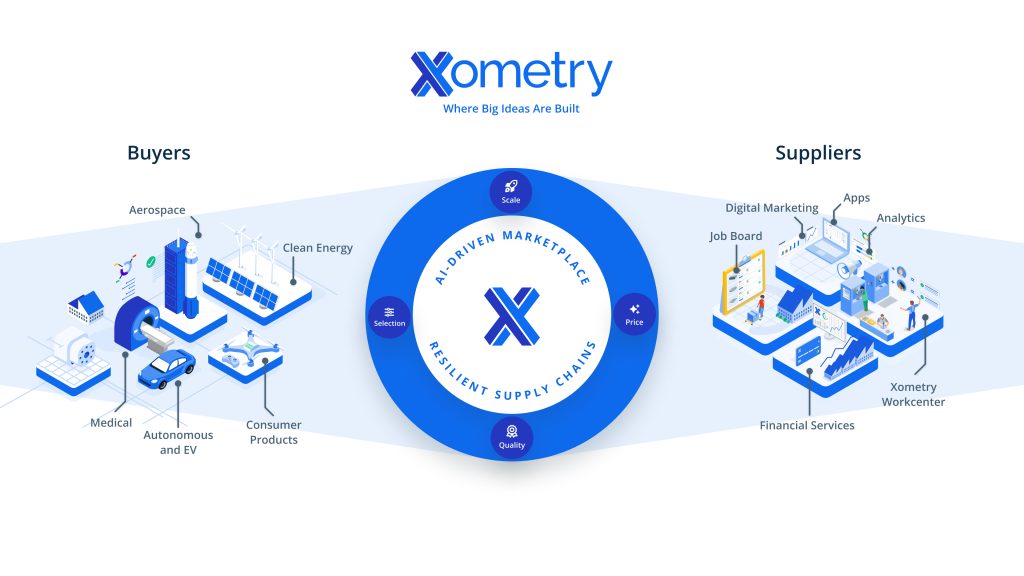

Altschuler highlights how the digital transition facilitated by Xometry not only simplifies procurement for buyers but also extends the market reach for suppliers, breaking away from the conventional local customer base. For instance, a manufacturing unit in Houston, previously catering solely to the oil and gas sector, could now effortlessly engage with aerospace or medical device companies across states.

One of Xometry’s notable advancements is the incorporation of Artificial Intelligence (AI) to ease the pricing process in manufacturing. Unlike the tedious manual shared costing method, Xometry’s AI-enabled platform offers instant pricing, a feature Altschuler considers vital for a seamless user experience akin to other online retail platforms. He elaborates, “We’ve got to find a way to give them instant pricing so they can experience the same sort of user journey that they would have in many other parts of their lives.”

Furthermore, the AI continues beyond pricing; it smartly navigates the matchmaking between buyers and suppliers, optimizing for a perfect fit, a function previously obscured by geographical and informational limitations. Altschuler explains, “We’ll use AI not only to create sensitive pricing, but we’ll use AI to optimize the match between the buyer and the supplier.”

Read more in the 3D Printing Industry Executive Interview series.

Xometry Upholds Quality Assurance Through Rigorous Vetting and Technology

For customers, quality and timely delivery are primary concerns. Xometry entails a stringent vetting process for supplier inclusion. Altschuler emphasized, “Quality is paramount irrespective of price, reliable delivery.” Prospective suppliers to the Xometry marketplace undergo a meticulous application and evaluation process. The vetting encompasses practical tests with parts financed by Xometry, followed by a cautious and progressive amplification in the volume and complexity of work assigned to them. Altschuler detailed, “We test them with parts, which we pay for, and then we use algorithms to very methodically but slowly and conservatively, amp up how much work they can take and what kind of work they can take.”

Upon qualifying, suppliers aren’t immediately laden with intricate tasks or tight deadlines; instead, they commence with simpler assignments. Their performance on various fronts, including timeliness, quality, and responsiveness, is continually assessed and scored. This scoring system, powered by technology, helps dictate the volume and nature of work a supplier can undertake, thereby ensuring a consistent quality output across the board.

This structured approach is a cornerstone in managing Xometry’s extensive network of over 10,000 manufacturers. Altschuler mentions the utilization of technology to oversee this massive network effectively, showcasing how Xometry is leveraging digital tools to uphold quality standards while navigating the challenges of awareness and traditional mindsets in the manufacturing sector.

Xometry Ensures Reliable Procurement, Thwarting Disintermediation Concerns

In the competitive landscape of digital manufacturing services, Xometry emerges as a reliable marketplace, negating concerns over disintermediation – a scenario where users bypass the platform to deal directly with suppliers. Altschuler highlighted the consistency, reliability, and exceptional customer service offered by Xometry, which, he argues, retains users on their platform even after they’ve identified the actual manufacturers.

Altschuler draws an analogy with Amazon’s third-party selling model to explain the trust and convenience Xometry brings. He stated, “Usually you don’t return to the third party seller because [on Amazon] it’s safe. It’s secure. It’s reliable. That’s what you treasure most, and that’s the same with our customers. They’re coming to us to get their parts done reliably.”

The aim, according to Altschuler, is to eliminate friction not just for customers but also for suppliers. Xometry simplifies the procurement process, making it easy for suppliers to receive files, purchase orders, and payments promptly. This streamlined operation allows suppliers to concentrate on their core competency—manufacturing parts.

Xometry’s strategy echoes a broader digital transformation akin to how platforms like Spotify have simplified access to music. This focus on reducing friction underscores Xometry’s bid to become an indispensable link between buyers and suppliers in the manufacturing domain, ensuring a seamless, trustworthy transaction environment for both parties.

Design the trophy for the 2023 3D Printing Industry Awards.

Xometry’s Meteoric Rise Fueled by International Expansion and Deep Customer Engagements

Xometry has seen a meteoric rise in its growth trajectory, buoyed by international expansion and deeper engagements with existing clientele. As per CEO Altschuler, from 2020 to 2022, the firm witnessed a staggering compound annual growth rate (CAGR) of around 83% in revenue, a testament to its aggressive growth strategy.

The company initially focused on the U.S. market but launched in Europe at the end of 2019, marking the onset of its international strategy. “Our international revenue grew from $3 million in 2020 to almost $33 million in 2022,” Altschuler notes. Europe, followed by expansions into the UK and Asia, particularly China, became critical growth avenues. Xometry has localized its service, offering it in 13 languages and six different currencies, embodying a ‘local for local’ approach by connecting local customers to local manufacturers.

Domestically, the firm has emphasized not just acquiring new customers but also “going deeper and deeper into our existing customers.” Altschuler shares a notable metric with investors each quarter – the percentage of revenue derived from existing accounts, which has consistently hovered around 95%, illustrating the depth of Xometry’s customer relationships.

On the business model, Altschuler clarified that Xometry acts as the “seller of record,” assuming the risks associated with price and lead time guarantees, offering a buffer between customers and suppliers.

The diverse customer base spans many verticals including aerospace, robotics, medical devices, automotive, and industrials. By not being tethered to a giant in-house machine shop but instead relying on a network of specialized suppliers, Xometry has maneuvered into such verticals. This network, coupled with its extensible technology, enables the firm to cater to the specialized manufacturing needs across industries, further propelling its robust and durable revenue growth.

Xometry Sees Surge in Next-Gen Manufacturing Amid Broader Industry Trends

Xometry has its finger on the pulse of evolving industry trends thanks to a wealth of data flowing through its platform. The firm is witnessing a growing emphasis on next-generation manufacturing, particularly in sectors like aerospace, renewable energy, and sustainable farming aimed at combating climate change. There’s also a noticeable uptick in innovation within the medical devices sector and a significant push towards electrification in the automotive domain.

Altschuler underscores a growing worry among customers regarding supply chain resilience amidst challenges posed by the pandemic, extreme weather conditions, and geopolitical tensions. He notes, “Customers are very concerned; they must have their parts or assemblies. Even if there’s a disruption, their supply chain needs to continue unaffected.” The distributed network model that Xometry operates allows for a level of local resilience that is pivotal in these uncertain times.

On the production front, Xometry is experiencing a shift from prototyping to small-series production and end-use parts. Altschuler believes that the firm’s public status, via a NASDAQ listing in 2021, and a proven track record with a significant portion of the Fortune 1000 and global brands have bolstered customers’ confidence in entrusting Xometry with their end-use parts.

Discussing material preferences, Altschuler indicated a balanced growth across metals and polymers, refuting any pronounced bias towards one material. He states, “We’ve seen robust growth everywhere,” suggesting a holistic expansion across all sectors and material types.

Xometry Aims to Revitalize Local Networks

Altschuler delineates the firm’s edge in the competitive landscape, highlighting its emphasis on local network development across the US, Europe, and Asia, in contrast to competitors primarily outsourcing to Asia. Altschuler underscored the importance of nurturing small manufacturers, stating, “The success of Xometry and all manufacturing around the world depends on the health and well-being of the small manufacturers.”

Xometry, according to Altschuler, is not just contending with other digital marketplaces but is also vying against traditional procurement methods. He believes the primary competition is the “old way of doing business,” where customers stick with familiar, local suppliers. He mentions, “Our biggest competitor is the old way of doing business. Getting people to change that mindset is a secular shift.”

This narrative aligns with a broader industry trend of revitalizing local manufacturing, albeit with a digital twist. Xometry’s approach of digitally connecting buyers with local manufacturers not only challenges traditional procurement methods but also aims to invigorate small-scale manufacturing entities, which are often overshadowed in a globalized supply chain.

Xometry’s Acquisition of Thomasnet to Broaden Offerings and Enhance Supplier Network

Xometry’s CEO shed light on the strategic acquisition of Thomasnet, aiming to expand the scope of offerings to customers while fortifying its supplier base. Thomasnet, a company with a robust search engine for industrial products, boasts over 500,000 North American suppliers and more than a million users. “It was very symbiotic for us to bring together Thomas with Xometry,” Altschuler said, emphasizing the synergy between Thomasnet’s substantial database and Xometry’s vision to be a “one-stop-shop” for customers.

Altschuler also spoke on the integration process, stressing the importance of merging cultures to forge a unified entity. The reorganization now aligns with the needs of buyers and suppliers, seamlessly incorporating Thomasnet into Xometry’s operational framework. Through this strategic move, Xometry not only broadens its service spectrum but also aims to consolidate a dispersed supplier network further, thereby enhancing the overall value proposition to its stakeholders.

He asserted, “Thomasnet blows open to different categories of things that we can offer,” hinting at the potential for diverse industrial solutions emanating from this union.

Xometry Aims to be the Defacto Rails for Custom Manufacturing Leveraging AI

Xometry envisions itself as the go-to platform for custom manufacturing, creating a seamless interface between designers and manufacturers, according to CEO Randy Altschuler. By offering plugins with popular 3D CAD programs like SolidWorks and Autodesk, and integrating with procurement systems such as Ariba or Coupa, Xometry aims to “remove that friction” for both engineers and purchasers.

Altschuler emphasized the potential of Artificial Intelligence (AI) in transforming the manufacturing landscape, highlighting its role in optimizing pricing, supply chain decisions, and material selections. He stated, “Using AI to help make those choices or inform the customer of the best choices is super powerful.” The AI-driven approach aims to navigate numerous manufacturing choices, ensuring optimal decisions that could significantly impact the final product.

Moreover, Xometry seeks to be indispensable for suppliers through its marketplace and free software tools. One notable initiative is the launch of a Manufacturing Execution System called Workcenter, offered free to manufacturers, many of whom Altschuler notes “can’t afford to buy an MES system.”

With over 44,000 people making purchases through Xometry in the past year, including many from the Fortune 1000, the platform is poised to gather invaluable insights across industries. Altschuler attributes his ability to stay ahead of tech trends to continuous customer feedback and a knowledgeable team, ensuring Xometry remains at the cutting edge of manufacturing technology.

In the broader picture, Xometry’s ambition to be the default platform for custom manufacturing underscores a move towards digitally-driven, AI-enhanced solutions in the manufacturing sector, fostering a more cohesive and efficient industry ecosystem.

Xometry Focuses on Profitability Amid Revenue Growth and Macro Economic Uncertainties

Xometry, a custom manufacturing marketplace, underscores its journey toward profitability amidst robust revenue growth and an expanding global footprint. The firm is set on achieving “adjusted EBITDA positive” status while continuing to grow revenues and extend its international reach, which currently contributes about 10% to the overall revenue, aspiring to hit 40% in the near future, according to CEO Randy Altschuler.

To become the default platform for custom manufacturing, Xometry navigates a challenging macroeconomic landscape described by Altschuler as “funky,” where rising costs due to inflation pose risks. Interestingly, Xometry has mitigated some of these cost pressures for customers. Altschuler notes, “a lot of our cost to customers have gone down” thanks to the firm’s expanding network and smarter AI, which can help find lower-cost suppliers.

In terms of assessing the company’s growth, key metrics include the number of active buyers, which saw the “largest sequential growth in new active buyers from Q4 to Q1,” and the increase in customer accounts spending more than $50,000 on a last 12-month basis, which grew significantly year over year. These metrics, Altschuler suggests, indicate the “underlying strength” of Xometry’s marketplace.

Xometry Leverages Industry 4.0, Aiming for Sustainable and Resilient Manufacturing

Altschuler believes in the potential of Industry 4.0 to redefine manufacturing by enhancing digital capabilities. “It unleashes a lot more that can be done digitally. It empowers buyers, and frankly, it will help the suppliers,” he noted, underscoring the evolution towards a digital-twin-driven manufacturing ecosystem.

Global supply chain disruptions have prompted a rethinking of traditional manufacturing strategies. Altschuler suggests an “integrated solution” as a smart move, where businesses can mitigate risks associated with far-flung supply chains. He remarked, “It’s more than just hedging your bet. You’re going to create an integrated solution. I think that’s best in class.”

On the sustainability front, Xometry has introduced a carbon calculator to help customers understand the environmental impact of their part manufacturing choices. This tool, part of a partnership with Gravity Climate, allows customers to compare carbon emissions between manufacturing processes and purchase offsets. “We’ve got more and more corporate customers in particular who need that data quarterly for compliance reasons… and more and more companies, rightfully so, are trying to figure out how do I reduce my footprint?” Altschuler explained.

In today’s high-tech era, where software is more often than the primary example given of “tech,” Altschuler, highlights the important role of manufacturing. As he sees it, t. He lamented the underestimation of manufacturing, stating, “The value of a manufacturing worker has never been higher.” He envisions a parallel appreciation for manufacturing and software engineering, as both disciplines are crucial for developing solutions to global challenges.

Altschuler underscored the nuanced skill sets required in contemporary manufacturing, mentioning that it’s not merely about physical labor but entails programming, machine operation, and more. As the world gravitates towards hardware solutions for pressing issues, he anticipates a growing acknowledgment of manufacturing’s significance.

Discussing the narrative around the value of manufacturing workers, Altschuler suggested that a well-rounded appreciation for manufacturing could contribute to a balanced understanding of its role in advancing technological innovations. Altschuler advocates for a broader recognition of manufacturing’s indispensable role in the high-tech landscape, echoing a sentiment for elevating the stature of manufacturing in line with other high-tech sectors.

Follow the full coverage of Formnext 2023 here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Randy Altschuler. Photo via Xometry.