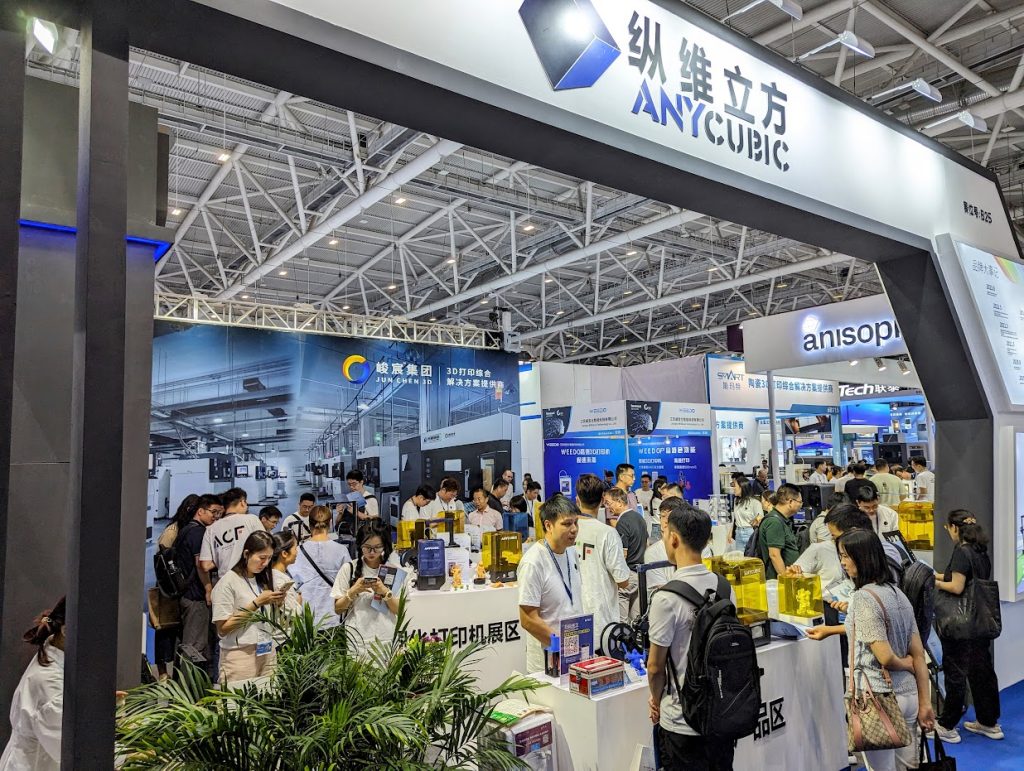

Anycubic has carved a niche in a fiercely competitive desktop 3D printing market. During my recent visit to Formnext South China I sat down with James Ouyang, the Vice President of Anycubic, in Shenzen to delve into the company’s journey, ethos, and vision for the future.

“To be honest, I’m not a maker. I joined Anycubic in 2016 because the CEO, Bryant [Ouyang], was my childhood buddy,” was the candid response to my initial question about how the VP got into the 3D printing industry.

Ouyang painted a vivid picture of Bryant’s initial foray into trading electronics and how a discernible trend in the market demand for 3D printing and its accessories led to a pivot in business strategy. “Bryant started thinking, ‘Hey, I can make this 3D printer they sell’,” Ouyang shared.

Ouyang’s own journey is equally intriguing. A graduate of the University of Auckland in New Zealand, he specialized in Materials Engineering, a field closely related to 3D printing. “I still remember the day. I was teaching at a university in Chendol, a beautiful city in the southwest part of China.”

Ouyang’s specific role at Anycubic is to manage the R&D department. “Most of my interest is in R&D and products.” He also highlighted his involvement in decision-making processes related to financial matters, given his position on the board.

Anycubic’s rapid growth is undeniable. From its humble beginnings to now boasting a workforce of “700 plus” employees, the company’s trajectory is impressive. Curious about the secret sauce behind Anycubic’s success, Ouyang attributed it to three distinct stages. Firstly, e-commerce and logistics expertise. “At the very beginning, we knew all about e-commerce. Bryant was a specialist in international logistics,” Ouyang noted. This foundation allowed Anycubic to deliver products efficiently and on time. Second, a robust supply chain. Capitalizing on the supply chain around Shenzhen, Anycubic could source components faster and at competitive prices. “We built up our own supply chain,” Ouyang emphasized. And third, investment in R&D. “As the business grew, we started to hire more R&D people,” Ouyang shared. This focus on research and development enabled Anycubic to stay abreast of the latest technologies and even introduce new ones to the consumer-grade 3D printing sector.

Ouyang’s passion for innovation shone through as he recounted Anycubic’s product evolution, from their initial Kossel delta 3D printer in 2015 to the subsequent i3 Mega in 2016 and Photon series of resin systems launched in 2017. “We wanted to bring great details and beautiful prints to the users,” he said, highlighting their venture into resin printers and, briefly, desktop metal printing.

With nearly 30% of their workforce dedicated to R&D, Anycubic’s commitment to research may surprise some.

Nominate now for the 3D Printing Industry Awards 2023.

Anycubic’s next phase

In the bustling tech hub of Shenzhen, where the average lifespan of a startup is less than three years, Anycubic stands out as a beacon of resilience and innovation as the company is currently celebrating its eighth anniversary. “The only way is to put more resources in the R&D,” Ouyang emphasized, drawing a parallel between the company’s strategy and the renowned Chinese liquor, Maotai, or Apple products. The essence? Quality products don’t need aggressive sales tactics. They sell themselves.

On the topic of business longevity, especially in a city like Shenzhen, Ouyang’s perspective was enlightening. Shenzhen’s openness, especially from a governmental standpoint, has been pivotal. The city doesn’t stifle businesses with excessive control, allowing them to flourish. Coupled with a young, talented workforce and a mature supply chain, Shenzhen offers a unique ecosystem for businesses to test and validate their ideas swiftly.

Ouyang highlighted a pivotal transition for Anycubic: “We’re kind of in the transition from market-driven to product or technology-driven,” he remarked, emphasizing the rapid pace at which the 3D printing market is evolving. This shift underscores Anycubic’s approach to staying ahead of the curve, ensuring they remain not just relevant but also innovative in a saturated market.

When asked about the company’s vision amidst this transition, Ouyang was clear: “We have to keep up with all the new technologies.” He acknowledged the rising competition, citing new entrants like former DJI employees who founded Bambulabs and Anker. “For us, we must keep up with the new trends, like high speed, good print finish, and user-friendliness,” Ouyang elaborated. He hinted at potential ventures into color printing, emphasizing the importance of out-of-the-box functionality for modern consumers.

When quizzed about the company’s product differentiation, Ouyang’s answer was straightforward, “It’s easy to think that you can do anything… but it’s more valuable when you choose not to do that thing.” For Anycubic, the mantra has been about focus. While they have dabbled in dental printers and even 3D printing metal, the core of their business remains consumer-grade 3D printing.

On potential expansion into the industrial sector. Ouyang was candid: “We’ve thought about that, but for now, we will not.” He emphasized Anycubic’s commitment to the consumer-grade 3D printing area, citing the vast differences in requirements and sales dynamics between consumer and industrial sectors.

Diving deeper into Anycubic’s user base, Ouyang revealed that most of its users seek detailed prints, such as jewelry or desktop models. “Our major user base is in the consumer resin 3D printing,” he noted, indicating a 60-40 split in favor of resin over FDM (Fused Deposition Modeling) in their product sales.

On the topic of revenue, Ouyang shared a ballpark figure of over 1 billion RMB, translating to more than half a million unit sales. This impressive number hints at Anycubic’s significant market share in the 3D printing sector. On the geographical distribution of their business, Ouyang revealed that “more than 90% of our business is overseas.”

Discussing the global 3D printing user base, Ouyang estimated it to be over 3 million people worldwide, based on a Facebook survey. He emphasized the changing dynamics of the market, where earlier enthusiasts loved building things, but modern users prefer ready-to-use products. “They want it to work,” Ouyang succinctly put it. Interestingly, while the global maker culture thrives, Ouyang pointed out that China’s maker culture is distinct. The convenience of procuring parts from platforms like Alibaba and Taobao means that many in China are more inclined towards 3D printing services rather than owning printers. This insight, Ouyang believes, could shape the future direction of the 3D printing industry in China.

As for Anycubic’s future, Ouyang envisions a stronger focus on R&D and a commitment to providing local support to its users. He sees a future where the hassles of resin printing, such as the smell and post-processing, are things of the past. But for now, the company remains grounded, valuing the lessons of the past eight years and looking ahead with cautious optimism.

Charting the Future of 3D Printing in China

In the heart of Shenzhen, a city renowned for its technological prowess, the 3D printing industry is undergoing a transformation. James Ouyang, Vice President of Anycubic, delves into the nuances of operating in this dynamic environment and the company’s vision for the future.

“We don’t have specific support from the government in terms of giving resources to the 3D printing industry,” Ouyang began, addressing the role of the Chinese government in the sector. However, he highlighted the supportive policies in place, such as tax breaks for R&D and incentives for manufacturing. These policies, while not exclusive to 3D printing, have undoubtedly facilitated the growth of companies like Anycubic.

Education, Ouyang believes, is another area where the government is playing a pivotal role. The STEAM education program, which integrates science, technology, engineering, arts, and mathematics, encourages students to delve into new technologies, including 3D printing. Schools are incentivized to incorporate this technology into their curriculum, emphasizing its importance in the modern tech landscape.

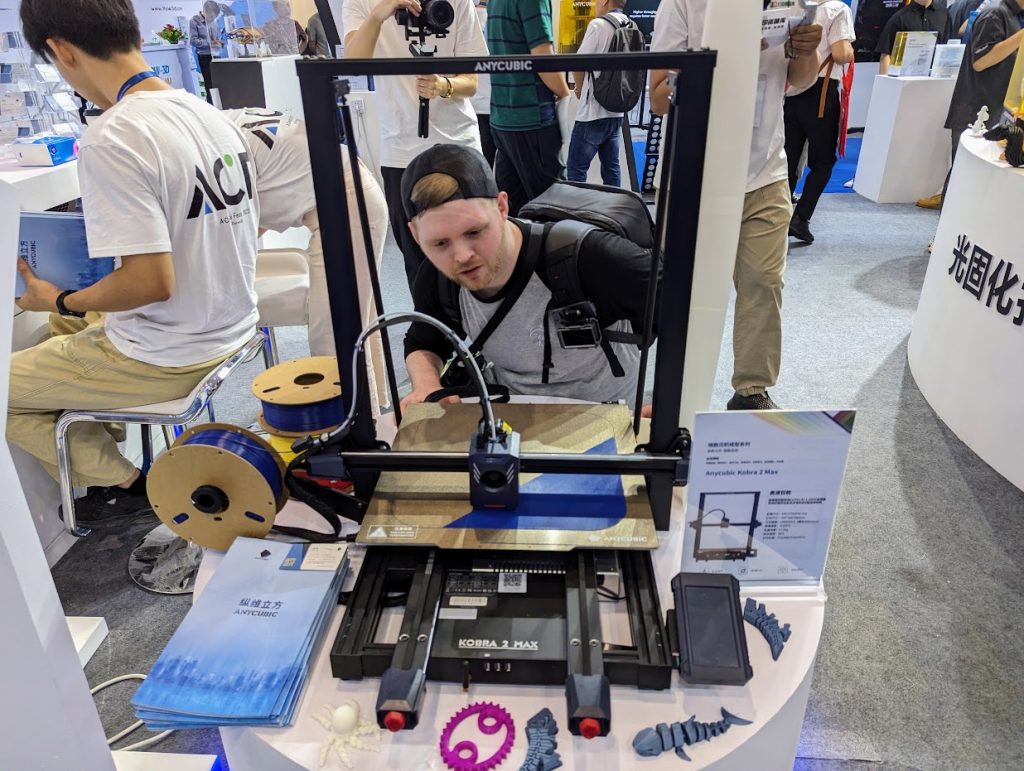

But what truly sets Anycubic apart in this competitive market? Ouyang was eager to discuss the company’s latest offerings. The Anycubic Kobra 2 Pro, for instance, boasts a maximum speed of 500 mm/s, a significant leap from its predecessors. This 3D printer, Ouyang claims, can produce a typical Benchy print in just 15 minutes and 43 seconds. Such advancements are not just about speed; they’re about efficiency and precision, ensuring that quality is not compromised.

Ouyang also touched upon the challenges of resin printing, particularly the post-processing steps that many find cumbersome. The company’s Wash & Cure Max aims to address these issues, offering a more streamlined and user-friendly experience.

In a rapidly evolving tech landscape, companies like Anycubic are not just keeping pace; they’re setting the tempo. With a focus on innovation, user experience, and education, the future of 3D printing in China looks promising indeed.

Subscribe to our newsletter for more news from Formnext + PM South China 2023.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows James Ouyang Vice President of Anycubic. Photo by Michael Petch.