I visited the London office of Luke Smoothy, founder of Get It Made, a company specializing in advanced manufacturing techniques, including CNC machining and 3D printing.

Smoothy’s journey began with a childhood fascination for the “business of making things.” Designing office furniture and spending countless hours on CAD in his early days, he was drawn into the nuances of product creation. Despite a love for the design and prototyping processes, he highlighted a challenge, “Just how hard it was to deal with a lot of manufacturers.”

It’s a familiar tune in the manufacturing world, where service providers often forget that they are, first and foremost, in a service business. Smoothy recalls when prompt replies and regular feedback were luxuries, not the norm. But amidst these challenges, he found a few responsive factories – notably one in China. These establishments breathed a fresh perspective into his manufacturing experiences, setting the stage for Get It Made.

Started as a “side hustle,” Smoothy’s company responded to a gap he saw in the market. While competitors, fuelled by massive venture capital investments, raced to remove the human element, Get It Made consciously chose the opposite path. Smoothy elaborates: “A lot of our clients come to us for this human interaction… they’re gonna want to know, ‘how’s the project going?’ rather than just upload their CAD files and check out.” It’s a unique pitch in a world moving increasingly toward automation.

Yet, there’s no denying the influence of technology on manufacturing. The conversation shifts to 3D printing, which Smoothy admits he was initially “a bit antsy” about. He saw it as a commoditized service, with standard machines and materials leaving little room to add distinctive value. However, his stance has evolved with the times.

Make your nominations for the 3D Printing Industry Awards now.

Tech City: London as a 3D printing hub?

London, as a 3D printing hub, seems an interesting choice. Many might point to Munich or Hamburg as Germany’s 3D printing powerhouses, yet the British capital has its own hidden community of digital creators. “There are actually several people like us in London. 3D Print UK, 3D People, and others,” Smoothy noted. While setting up in London was initially a decision of convenience – “I’ve always lived here,” he said – the city’s potential as a 3D printing center is undeniable. London’s draw remains its magnetism for talent. The vibrancy and diversity of the city ensure a steady influx of expertise.

However, London’s reputation as a digital powerhouse leans heavily towards software rather than hardware. The London Tech Week, for example, remains biased in favor of digital services, prompting questions about whether the city is doing enough to foster its hardware and manufacturing talent.

The challenge for London, however, is a classic one: space. “Space is expensive,” Smoothy lamented. When manufacturing needs to escalate beyond digital design and encompass processes like CNC machining, finding the right premises becomes a challenge.

Building a business

Discussing ‘manufacturing as a service,’ Smoothy elucidated the business model as a “one-stop solution.” The aim is simplicity. A focal point for this service model is an enhanced customer experience. From sourcing raw materials to complex assemblies, companies like Get It Made aim to ease the entire process. Smoothy added, emphasizing his vision, “If you need something made, you just come to us.”

Recruitment, though, is the toughest nut to crack. “It’s definitely the hardest part of my job,” Smoothy admitted. The challenge? Finding individuals with a blend of technical know-how and customer relations expertise.

Exploring newer horizons, Smoothy reveals their venture into the HP Jet Fusion 3D printers. This technology promises a dual advantage: a competitive edge and potential cost savings.

However, the pivot towards 3D printing isn’t merely about leveraging new technology. Smoothy sees it as a potential “gateway drug” to draw customers into their more lucrative services, noting that “3D printing is a much bigger market.” The integration of 3D printing is envisioned to supplement their existing manufacturing operations, making their business model even more robust.

The Battle of Platforms: Consistency vs Scale

Turning the conversation towards online platforms, Smoothy highlights some underlying concerns. There’s a mention of inconsistencies, with prices sometimes doubling after an initial quote and a lack of guaranteed quality when scaling orders. This unpredictability is where Get It Made sees its strength — in the delivery of consistent quality.

This consistency is hard-earned. Smoothy explains their deepening relationship with a primary factory in China, which has enabled the creation of “knowledge” and “consistency” over the years. While manufacturing is fraught with challenges, the capacity to address these problems head-on and find solutions has been a hallmark of their success.

This foundation has led to collaborations with big names like Ocado, Brompton, Airbus, and Stanley. Although many of their projects are confidential, Smoothy hints at their engagement with niche segments such as satellite parts – perhaps even of the CubeSat size.

This breadth extends beyond space to even the streets of London. One such venture involved creating aluminum extrusions for a budding electric scooter—a unique challenge in a market where most manufacturers demand massive quantities. Smoothy recounted, “Most manufacturers in the UK do not [produce small quantities]. They want two tonnes of aluminum, which would mean an extrusion that would be like a kilometer.”

At the heart of Get It Made’s ethos lies a commitment to supporting innovation at its grassroots. They’ve seen a growing trend of shortened product life and design cycles, with increased demand for novelty. This leads them to work with inventors, providing guidance when necessary. One intriguing project revolved around an attachment for a WD-40 can to clean bicycle chains – a niche yet innovative solution in the cycling world.

Their commitment to the broader community doesn’t stop with product design. They’ve initiated grants for budding entrepreneurs with a focus on creating impact. A notable instance of this initiative is their support during International Women in Engineering Day. “We chose a company led by a female founder. It’s a smart menstrual device that provides health information,” Smoothy explained. The grant, which ranged up to £10,000, facilitated prototyping and iterative designs for such groundbreaking products.

Another example is ManholeMetrics, an ingenious device that, as absurd as it sounds, alerts households to imminent sewage backup. While at first glance, it might be dismissed as a novelty, Smoothy pointed out the genuine practicality and market demand for such a solution. Diversifying beyond IoT, Smoothy touched upon their involvement with varied innovations, from fire detection systems monitoring large forested areas from a single point to more niche ventures like Flux Aviation’s exploration into semi-electric propulsion. Every project underscores Get It Made’s knack for identifying, nurturing, and scaling innovative ideas. And it’s not all high-tech: consider their collaboration with a company innovating in fish farming, with a camera system that monitors fish health in real-time.

“We mold up projects for them. Low volume injection molding because they’re never going to need masses”, Smoothy explained, alluding to the bespoke nature of their projects.

But scaling in a world dominated by giants brings its challenges. Being a smaller player, Get It Made has had to navigate the minefield of perceptions, aiming to project themselves as accessible and competitive. “We don’t want to appear too much like we’re just a very small, boutique kind of thing; we have the capability,” remarked Smoothy. This strategy seems to work, as they continuously find themselves shoulder-to-shoulder with industry behemoths.

Manufacturing as a service

The conversation naturally steered towards the future of manufacturing as a service. Surprisingly, Smoothy foresees a shift back to in-house manufacturing for many companies. External platforms can often lead to quality inconsistencies, and local machine shops are growing wary of being beholden to larger players.

Mentioning a company called Paperless Parts, Smoothy highlighted their game-changing approach. Instead of forcing automation, they aim to expedite the quoting process. A seemingly minor nuance, but one that can shake up the industry. This software-as-a-service solution for manufacturing may just be the tool to level the playing field.

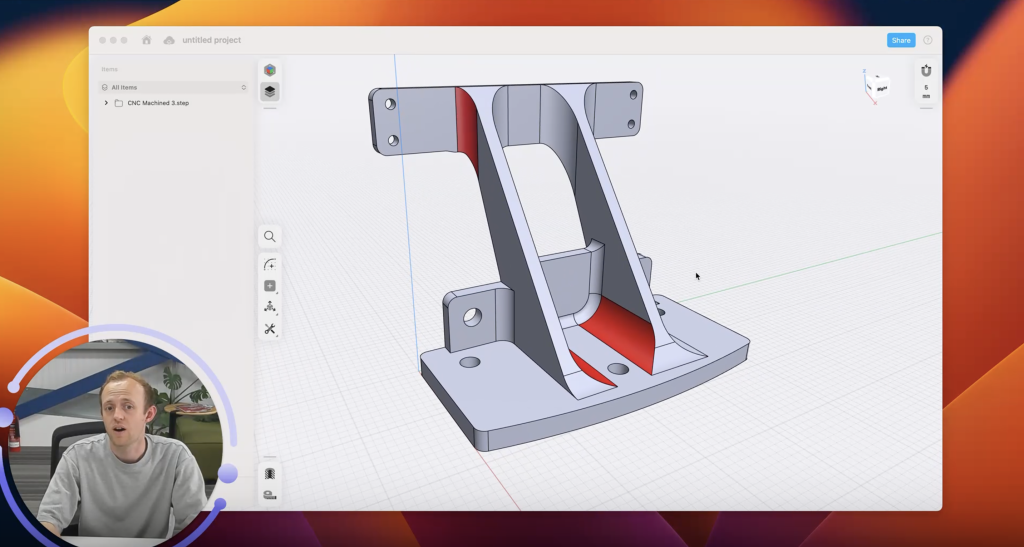

“There’s an ease to additive manufacturing, a sort of straightforwardness in terms of size and volume considerations,” Smoothy began, highlighting the contrast to the intricate decisions needed in CNC machining. Yet, he quickly pointed out the immense variables in the latter: “What’s in your tool room, what cutters, what fixtures, what’s the envelope for machining? So many variables.”

Get It Made integrates a digital approach to the traditional manufacturing process. “It’s like a digital Napster for manufacturing,” he quipped. Clients can upload CAD files, receive quotes, and manage their orders. Yet, amidst this automation, the human touch is pivotal. The team at Get It Made meticulously reviews each project, ensuring issues are caught early. As Smoothy candidly noted, “Sometimes, computer says no. But with human ingenuity, you can resolve the challenges.”

But what about the industry’s broader shifts and the trends shaping the 3D printing landscape? For Smoothy, it’s about marrying additive and subtractive processes. Many manufacturers avoid combining these methods, but Get It Made welcomes it. “We can 3D print in metal and then machine it afterward. This cross-pollination, I believe, could be a burgeoning trend,” Smoothy suggested.

In a world of automated production, the conversation serves as a reminder: innovation lies at the intersection of technology and human ingenuity. It’s not just about 3D printing the future—it’s about crafting it.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Luke Smoothy, Get It Made Director. Photo via Get It Made.