How do you product 3D printing enterprises against cyber-security risks?

Earlier this month the Digital Manufacturing Design and Innovation Institute (DMDII) launched a a $750,000 Cyber Hub for Manufacturing intending to tackle the issue of cyber-espionage attacks against the manufacturing sector.

The seed funding comes from the U.S. Department of Defense (DOD) and the project is part of a partnership with UI LABS.

According to a 2017 Verizon data breach investigation report, approximately 35% of all cyber-espionage attacks in the U.S. target the manufacturing sector.

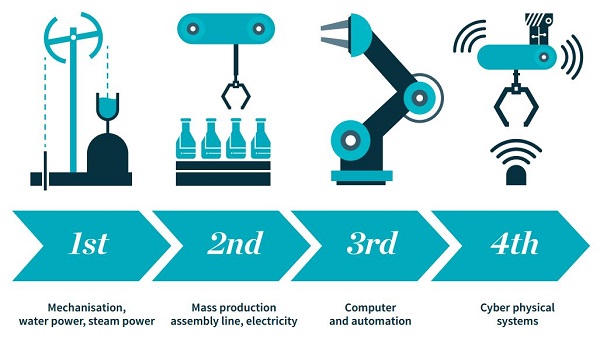

With industrial 3D printing taking a central role in the future of digital manufacturing and the emerging Industry 4.0 eco-system protecting assets is an important task.

I caught up with Thomas McDermott, Executive Director, DMDII to find out more about the Cyber Hub for Manufacturing, the vulnerable attack vectors and how enterprises can protect themselves.

“The launch of the Cyber Hub for Manufacturing embodies why DMDII exists,” said DMDII Executive Director Thomas McDermott in an earlier statement. “We need to think about securing our manufacturing equipment the way we secure our laptops, and the complexity of this issue means our partners will get there much faster by working together.”

3DPI: How does Additive Manufacturing/industrial 3D printing fit into state-of-the-art in digital manufacturing in America?

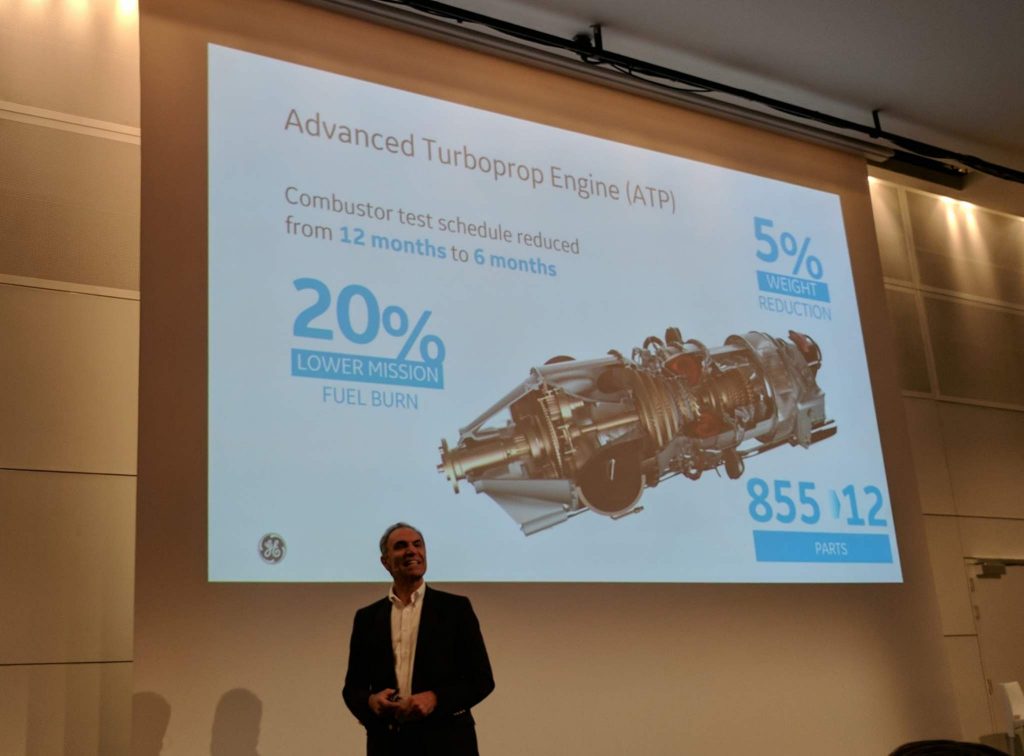

Thomas McDermott: Additive manufacturing is an increasingly capable and applicable process for a wide range of manufacturing applications. Most large and many small manufacturers are exploring how to best incorporate additive manufacturing into their workflow. The true transformation for manufacturers comes when additive manufacturing technologies are coupled with advancements in design capabilities such as generative design tools. When manufacturers can design superior products that human designers would struggle to conceptualize, and now can create those products where subtractive manufacturing was previously incapable, it creates the opportunity for step change improvements in product function, performance, and manufacturing cost.

3DPI: Can you say anything about cybersecurity threats specific to 3D printing or Additive Manufacturing, and how these can be addressed?

Thomas McDermott: The attack vectors for additive manufacturing are the same ones that present a cybersecurity threat for advanced manufacturing overall. They could be remote, local, or physical, and include well-known strategies such as malware infections that exploit vulnerabilities of CAD/CAM software or operating systems.

3DPI: What can you tell our readers about the project 15-07-05: From Art to Part?

Thomas McDermott: “From Art to Part” is a pioneering project in the metal additive manufacturing space. Led by GE Global Research, the project is bringing dramatic performance improvements to 3D-printed metallic additive manufacturing through an integrated digital simulation toolkit. The software under development leverages deep subject-matter expertise from University of Illinois Urbana-Champaign and University of Cincinnati to better predict microscopic interactions between metallic powder and the high-powered laser that fuses the powder into a solid. Ultimately, through better prediction and print simulation, this technology will decrease design development cycles for metal additive parts from 10-12 to 2-3 weeks.

3DPI: If manufacturers using 3D printing are concerned about cyber security, what should they do?

Thomas McDermott: As with any type of manufacturing, a security architecture that relies on a single point of protection is likely to be defeated in a cyber-attack. The general recommendation is for manufacturers to use an architecture that has multiple layers of defenses. Additionally, basic cybersecurity hygiene, which often involves significant culture change and the adoption of new policies, is of critical importance. This could include items such as forcing password changes, eliminating shared accounts, restricting equipment access based on user needs, and regularly completing equipment and software security updates.

DMDII is working to simplify the process of complying with cybersecurity protocols required to do business with the U.S. Department of Defense, and one of its project has resulted in a tool that streamlines the process and provides detailed suggestions and templates to attain compliance. As we stand up the Cyber Hub for Manufacturing at DMDII, additional resources for small and medium manufacturers to shore up their cybersecurity practices are forthcoming.

You can read more about cyber security risk in manufacturing in this article from Ralph Resnick, President and Executive Director, National Center for Defense Manufacturing and Machining (NCDMM) and Founding Director of America Makes.

More information about the DMDII’s 2018 Strategic Investment Plan (SIP) and Technology Roadmap is available online.

Stay up to date with 3D Printing Industry news by subscribing to the most widely-read newsletter in the industry, following us on Twitter, and liking us on Facebook.

Looking to get involved in a new additive manufacturing project? Join our new 3D printing jobs service now.

Vote now in the 2018 3D Printing Industry Awards for technologies and research projects of the year. Want to design the trophy? Enter the 2018 3D Printing Industry Awards design competition. sponsored by Protolabs now.