When people think about 3D printing technology, or just 3D technology in general, software usually takes the backseat while enthusiast gush over 3D printers and other forms of hardware. But, whether you know your way around software tools or not, you can’t deny that software is what runs our favorite physical tools. Today, and in many keynotes and exhibitions throughout the week at Inside 3D Printing New York, software finally gets its well-deserved time in the spotlight.

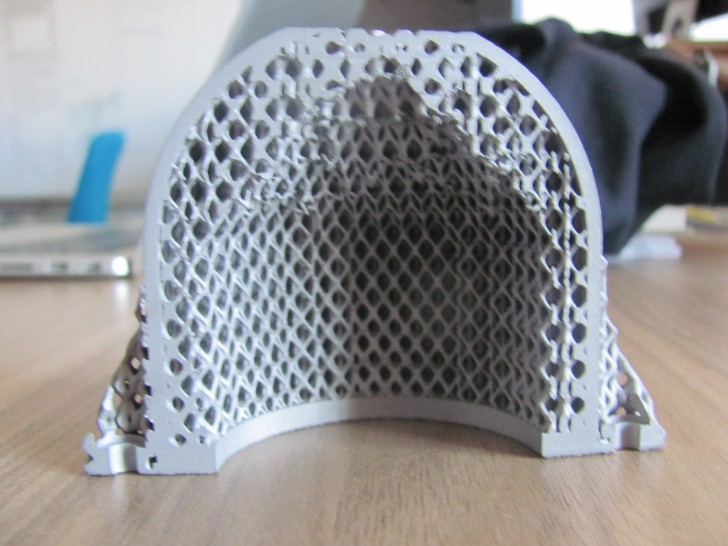

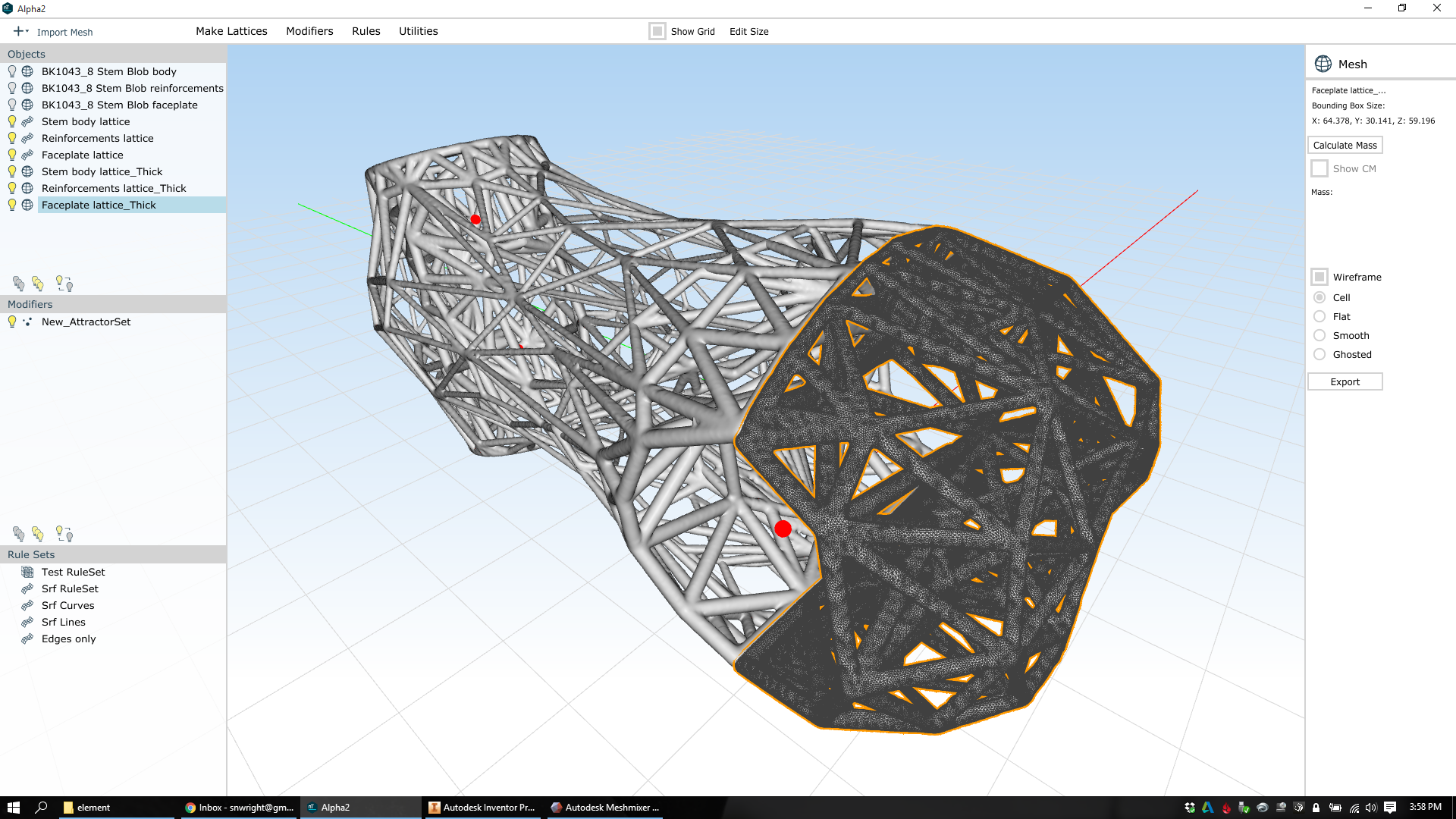

For instance, the co-founder of NYC-based software company nTopology, Brad Rothenberg, hosted a workshop earlier on this week at Inside 3D Printing, where he gave a tutorial for their new nTopology Element software. The program is focused on generating lattice structures, complex and lightweight bone-like structures, using algorithms and rule sets to create optimized parts that are both highly unique and beneficial. Lattice structures are ideal for a wide-range of industries, from aerospace to footwear, and, with nTopology’s Element software, they have been engineered for additive manufacturing in a new way.

Just a couple of days before Rothenberg’s workshop at Inside 3D Printing, I had the opportunity to visit the nTopology office in Manhattan. While there, Rothenberg and I discussed the foundation of nTopology, the necessity for computer generated design, and why lattice structures are such a vital piece of the ever-expanding digital manufacturing world.

Rothenberg started by explaining where the idea of nTopology actually stemmed from. “The company was really kind of founded out of the problems I was having with a suite of design tools at the time while at school,” the founder says. “I was very interested in this idea of generative design, building systems to help create structures and geometry. Rather than just a traditional 3D model environment, where you’re just sculpting, this is more like composing. You’re building a set of tools that generate for you. I built a library of several different scripts and algorithms that were all about generating different kinds of structures based on kind of different generative methods. We were using these tools with other companies when we realized that were having the same issues with those current design tools.”

Utilizing their algorithms on contracted design projects eventually led Rothenberg, and fellow nTopology co-founder Greg Schroy, to realize that they could positively influence more people by making these algorithms into a production tool, instead of tackling this software issue project by project. He elaborates, “About a year into doing design projects, I realized that, one, the idea of software was a lot more interesting to me than doing design projects because, by making a tool that can do the type of designs we were doing, there’s a much more broad reach, you could reach a lot more people. Second, I really enjoy writing code and using that for design. The company really started with the problems we had with other software, mixed with our desire to become a product-based company. We realized that the valuable thing that we had were these algorithms, so we decided to think about how we could turn it into a production tool.”

So, why is 3D printing software so far behind hardware to begin with? Well, according to Rothenberg, the current state of CAD tools are in need of a major upgrade. As traditional manufacturing shifts into the digital realm, new tools (such as nTopology’s Element software) are needed to address these new styles of production. “I think that the current suite of CAD tools are based on a different generation of manufacturing, where it was all about documentation,” Rothenberg continues. “In the past, you had machine shops that would make parts for you, so a designer was always separate from the machine shop. CAD tools were built to make it as easy as possible for the designers to produce a set of documents for the machine shop to make the part. Now, with the new generation of tools, the documents are now the 3D files, the designer is much more closely connected. Those old CAD tools were never really focused on generating objects, so, while they were good at documenting stuff, they never really used the power of a computer to truly generate structures. I think the new generation of tools are really starting to focus on the generative process, where it’s making it easier for you to set up relationships between objects.”

The nTopology Element software is one of the first design tools of its kind, built from the ground up specifically for additive manufacturing. These structures, to me at least, are magnificent in both look and theory, but what are these lattice structures actually useful for? “Engineers working on complex parts, mainly in aerospace and even footwear. Basically you’re seeing this technology being really useful in any parts that have a really high degree of complexity or that need customization. Especially for additive manufacturing. For parts that don’t have a high degree of complexity, you’re not really maximizing what you can get out of the process. For example, in aerospace you get some parts that traditionally are made with 8 or 10 different components that are welded together, you can now make that in one part. By using lattice and cellular structures, you can make structures that are super lightweight, because you’re only adding material where it’s needed, so you have structures that are more related to bone.”

Now, although computer generated lattice design is a newfound approach for actual production via 3D printing, the idea has been researched for quite some time, and is reflected in the earliest stages of natural life. For Rothenberg and nTopology, the algorithms and rule sets that create these designs may make up the engine of their software, but they’ve ensured that the user is still in the drivers seat.

Rothenberg concludes, “For use and production, it’s a really new thing, but in terms of research this has been looked at for a pretty long time. But now you’re beginning to see these techniques be used in commercial software, it’s just moving from research into commercial tools. What sets us apart is that were the only people primarily focused on lattice design, while were still using the optimization algorithms, we’re putting the user in the center of the process. It’s much easier for the user to control the process throughout the different stages of the generative process, from generating the initial structure to iterating multiple options, to modifying and editing the structure afterwards, to meshing.”