Last week at Formnext 2021, Arburg’s InnovatiQ subsidiary, a specialist in silicone 3D printing, announced its latest silicone 3D printer on the show floor – the new LIQ 7.

Based on the firm’s Liquid Additive Manufacturing (LAM) technology, the LIQ 7 will reportedly enable full-color 3D printed silicone parts for the first time. According to InnovatiQ, customers using the new system will be able to closely control the color dosage of printed parts to achieve a wide variety of color mixes.

As far as applications go, the company expects the novel capabilities to see use in aesthetically pleasing wearable devices, consumer goods, and custom e-mobility components.

Alongside the announcement, InnovatiQ also showcased its older LIQ 320 3D printer for the first time in person, as well as several of its FFF 3D printer applications.

Silicone 3D printing with InnovatiQ

Formerly known as German RepRap, InnovatiQ was founded in 2010 as a manufacturer of industrial FFF (and later LAM) 3D printers. In 2020, the company was eventually acquired by machine manufacturer Arburg and rebranded under the InnovatiQ banner.

Owing to the niche nature of silicone 3D printing, the firm’s LAM printing technology makes it somewhat of a pioneer in the field, alongside competitors such as Spectroplast and WACKER’s ACEO.

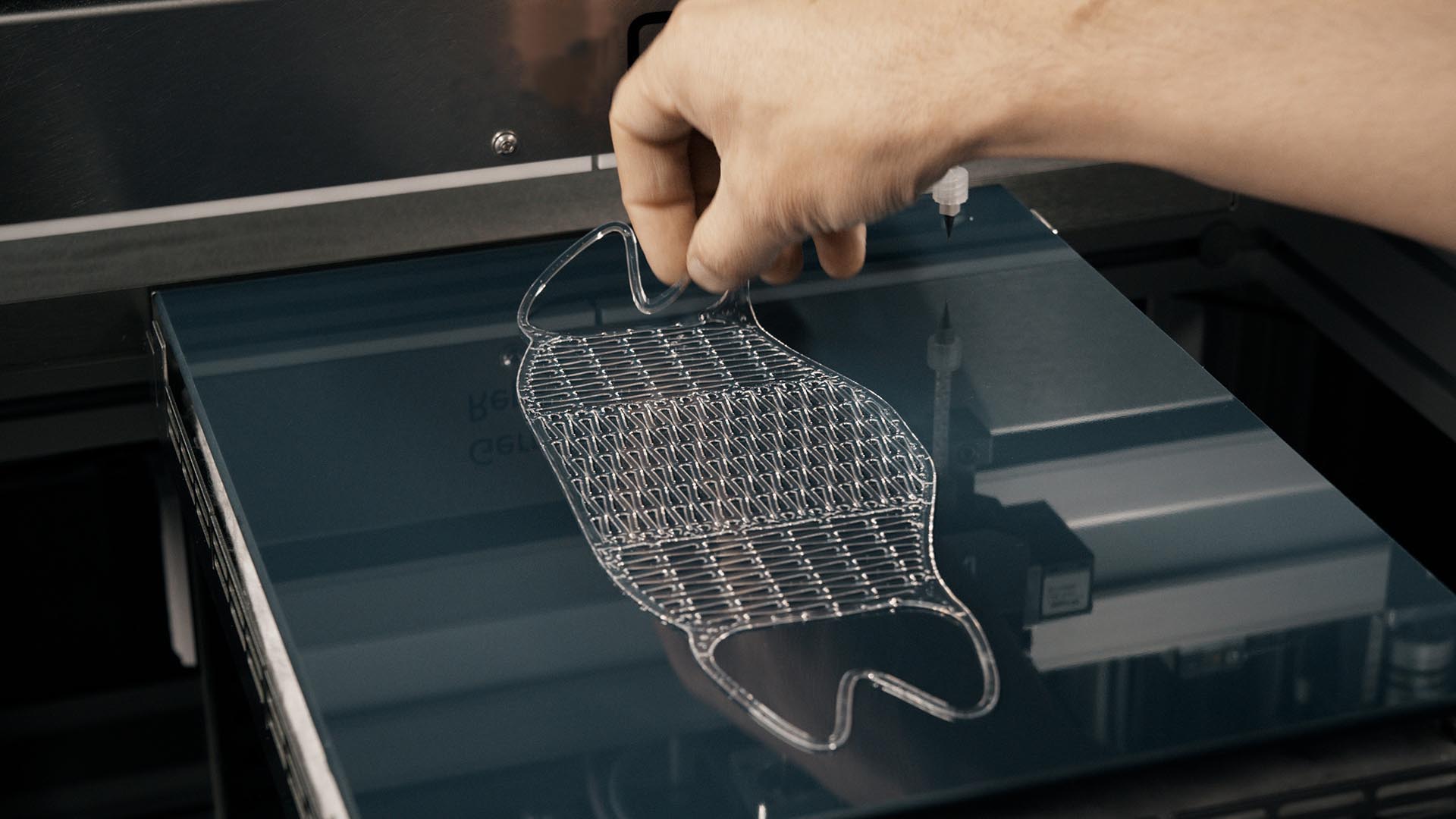

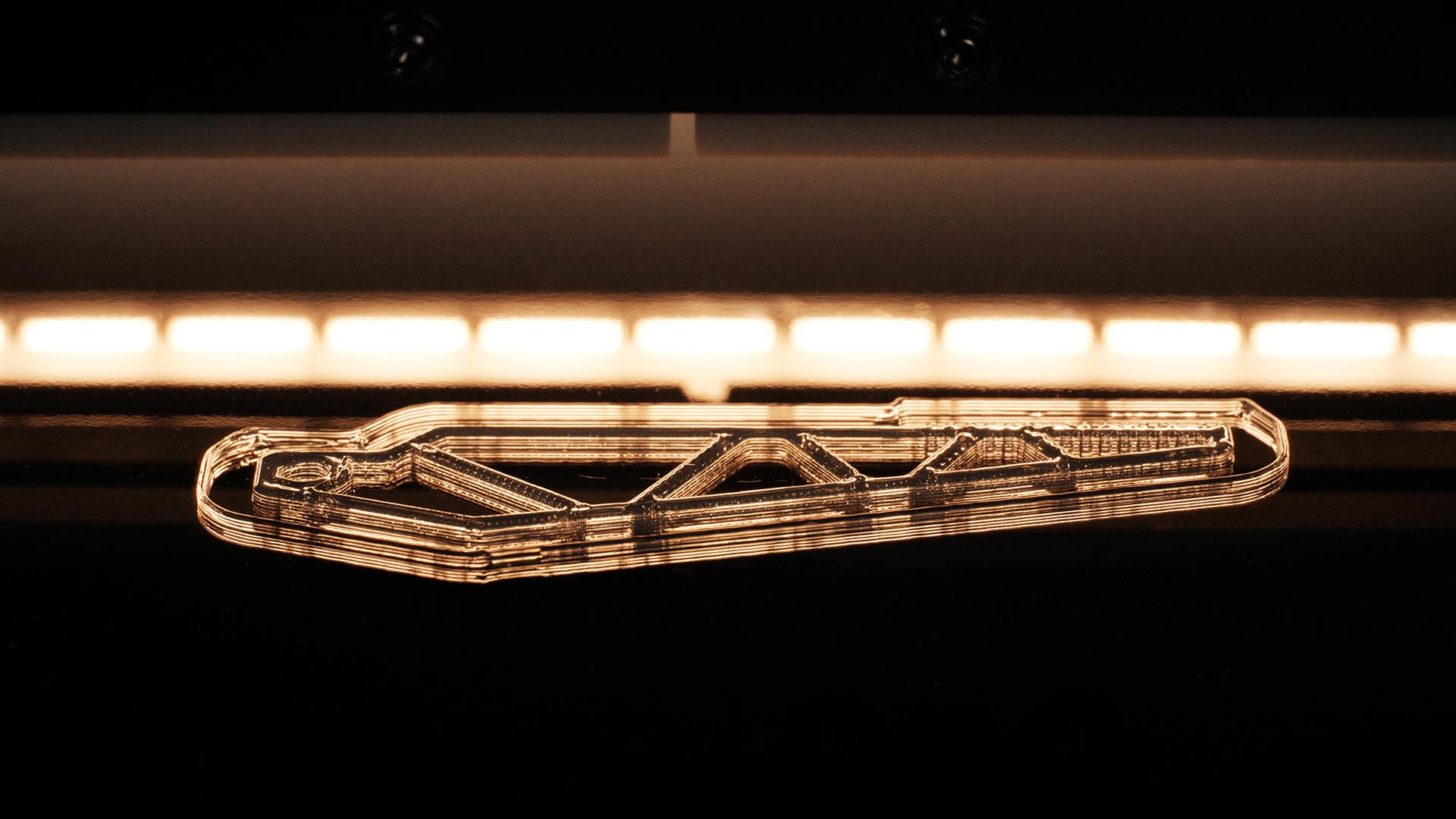

So how does the LAM process work? At its core, the technology works by vulcanizing the firm’s liquid silicone rubber (LSR) material in its liquid form under a heat source (halogen lamp) to thermally crosslink the material into a solid. According to InnovatiQ, this enables the material to maintain its high-performance mechanical properties, delivering 3D printed components that offer characteristics comparable to those of injection-molded silicone ones.

Additionally, parts printed via LAM do not require post-processing, meaning they’re ready for functional applications straight out of the build chamber.

InnovatiQ’s FFF 3D printing demonstrations

Naturally, InnovatiQ also showcased some of its FFF 3D printing technology at Formnext. Over at the Arburg booth, the firm presented its Gauss e-motorcycle case study, a project that demonstrated how 3D printing can enable both weight savings and more efficient use of battery technology at the same time.

Finally, parts 3D printed on the company’s large-format TIQ 5 system were also on display. This included housing for a hyperthermia device and a set of robust ventilation grills made of fiber-reinforced composite filaments. The TIQ 5 features a build volume measuring 500 x 400 x 450mm and a water-cooled dual print head.

With Formnext 2021 having just concluded, hundreds of companies had the opportunity to showcase some of their most recent developments. BigRep, a Germany-based manufacturer of large-format 3D printers, launched its latest set of FFF systems. The firm’s new BigRep PRO printer is designed to be an industrial powerhouse, offering a build volume measuring a cubic meter, while the revamped BigRep ONE is intended to be the company’s affordable offering.

Shining 3D, a China-based manufacturer of 3D printing technology, also launched a new resin-based 3D printer and a new 3D scanner at the trade show. The AccuFab-L4K printer combines a sizable build volume with a 4K resolution LCD, and is designed for both functional prototyping and low-volume end-use production for applications in engineering, medical devices, and more.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a silicone part 3D printed on the LIQ 320. Photo via InnovatiQ.