Though Innofil3D has been manufacturing 3D printing filament since 2012 as a white label business, the company launched as its own brand in 2013, becoming one of Europe’s leading producers of FFF/FDM filaments. Then, in February of this year, the company partnered with another Dutch business, CiorC, to release an increasingly expansive line of recycled filaments under the brand InnoCircle, with the idea that the Maker community was primed to start 3D printing with sustainability in mind. Though InnoCircle began with recycled ABS and PET, the brand has now branched out into the most widely used material for desktop 3D printing with six different colors of recycled PLA.

In a post on 3DPI, CiorC owner Jan Willem Slijkoord expressed the urgent need for sustainability, but also pointed out that data proves that many consumers are more than willing to recycle. Given the large demand for plastic filament in the growing 3D printing industry and the fact that plastics are the largest stream of raw materials for this evolving technology, he suggested that recycled filaments could be one contribution that Makers might make to reduce their environmental footprint. Slijkoord says, “We know that recycling is an effective way to reduce CO2 emissions and improve our sustainability. In addition, people are widely willing to enable its implementation.”

For that reason, InnoCircle was established, with Roger Sijlbing, Sales Manager for Innofil3D, suggesting that InnoCircle filaments are a much more sustainable alternative to existing filaments, from petroleum-based ABS to, even, biodegradable PLA. “Innofil3D believes that the 3D printing community can contribute to make current manufacturing methods more sustainable,” Sijlbing explains, “Our InnoCircle filaments save up to 50% in CO2 emission in comparison to silimar filaments made from oil or renewable feedstocks. So what better way to do this than with filaments for FDM printers? That’s why the company created InnoCircle.”

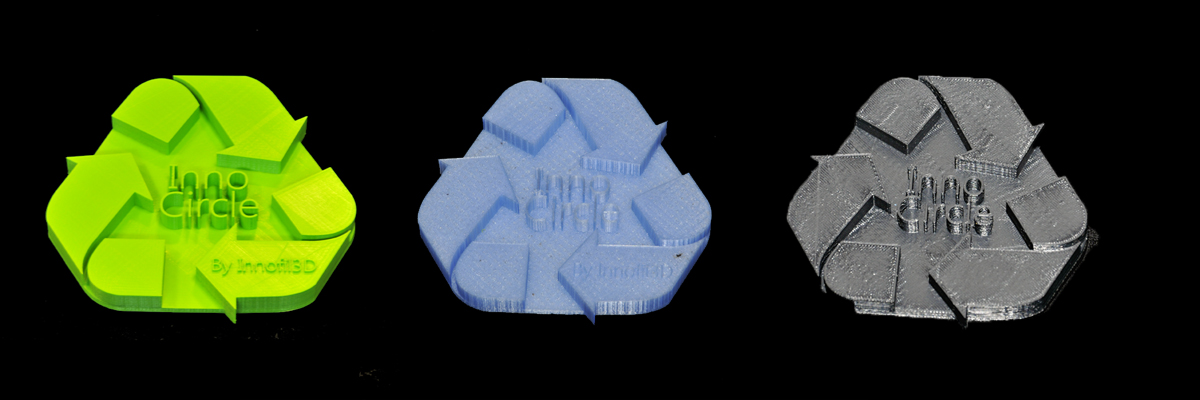

The company then turned to recycled medical appliances to create its rPET filament, consumer electronics for rABS, and, now, PLA packaging for rPLA. As high tech as the company’s efforts have been to produce these recycled filaments, which includes selecting high-quality sources, the team behind InnoCircle says that the most difficult challenge is encouraging widespread adoption of the recycled materials. Martin Faber, Ph.D. polymer scientist from Innofil3D, describes the sourcing process, “For us as a manufacturer, finding the right recycled source is key to ensure a high quality filament, which, in turn, creates a great customer experience. During the product development stage, we analyse and modify specific properties in our laboratory to create recycled filaments with the same printing qualities as a virgin product.” Faber continues, “As an example, most recycled plastic materials are black, limiting the coloration of the filament. Based on our development capabilities, however, we are now able to manufacture our InnoCircle PLA in any colour with great printing results.”

Slijkoord, however, suggests that the Maker community has, so far, received the recycled materials released so far, rABS and rPET, enthusiastically. “We receive more and more positive feedback from Makers who have tested InnoCircle filaments,” he says. “One member of global 3D printing platform 3D Hubs, even said, ‘The only thing I’ll say is that it was super easy to print with and that I think the results look awesome :)’ And they are not the only one. This is part of our DNA: creating innovative filaments with premium quality that ensure great customer experiences for both the home and the professional Maker. This is what we have achieved with InnoCircle.”

While petroleum-based plastics, like ABS, can be essential for a number of products, their contribution to climate change is unquestionable, making products like rABS, available in black, an essential step in moving away from an unsustainable production material. Now, with rPLA, InnoCircle is tackling the most widely-used material in the desktop 3D printing industry. And, because they will be offered in six different colors, the recycled PLA filament offers a much broader range of color than many other recycled PLA brands on the market. Available in rPLA will be sold in 1.75 and 2.85 mm diameter filaments in 750-gram spools beginning October 1st. Before then, Euromold attendees will be introduced to the complete line next week.

To learn more, Innofil3D’s Roger Sijlbing can be contacted via email at [email protected] or by phone at 00 31 6 16 40 11 97. You can also explore Innofil3D at their website or even read how InnoCircle material stacks up on 3D Hubs.