Founded in 2010, ATOA is a small group of companies based in Bangalore, India, which offers innovative services catered to engineers. These include the professional ATOA Scientific Technologies division, dedicated to providing Computer Aided Engineering simulation services, and ATOA Software Technologies, which develops engineering-focused Android Apps. It has now introduced the ATOA Smart Technologies division, which is entirely focused on 3D printing services.

Dr. Raj C. Thiagarajan, from ATOA, explained that the company, which now has 15 employees, offers in-house 3D printing though a MakerBot 2X and a Megabit desktop 3D printer, turning to external services for more industrial 3D printing technologies.

The division was built to design, engineer, and make custom 3D products and it is a natural consequence of the company’s specialization in engineering services. Its mission is evident in the Apps it has developed, which include such tools as Plate Calculator, and even more so in the company’s multi-physics simulations services. These include advanced multi-physics optimization (flow, structural, thermal, optical, chemical, and functional) for preliminary product design cycle and cost reduction, and multi-scale simulations for linking macro-engineering to micro-mechanics to nano-mechanics for products engineered from the atomic level.

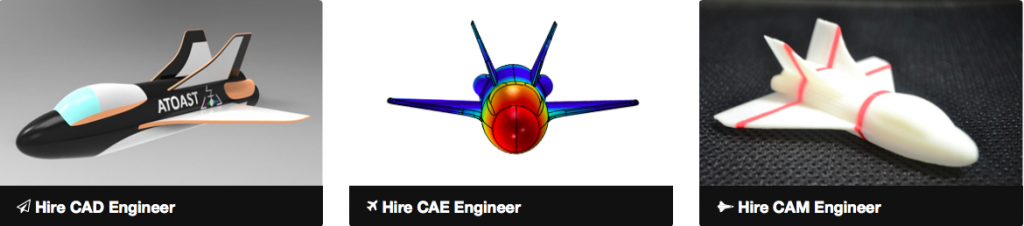

As an end-to-end simulation service provider, ATOA also offers its clients drawing, drafting, and meshing services, with additional services through its collaborative partners for material characterization, prototyping, experimental testing for validation and verifications and part performance evaluation. With the addition of 3D printing, the company is now able to offer full CAD, CAE, and CAM services. Users can hire an engineer specifically for each one of these areas or start by uploading a concept sketch in order to get a CAD model created, and then use the digital model to get a final product made. The entire production process with one single interlocutor. This is how modern development takes place and 3D printing was the last piece of the pie necessary to bring it full circle.