Accessories company Incase and 3D printer manufacturer Carbon have announced a research and development partnership for mobile device protectors.

While the 3D printing community has 3D printed mobile phone cases since the dawn of time (at least B.C ? – Before Carbon – Ed.) these cases are different and made with “never-before-used materials”.

The notable thing here is that Carbon’s 3D printing technology will be used to mass produce the phone cases and other protective devices. The retail cost has not been provided, but this marks a further piece of 3D printing for production news from the company – joining the adidas Futurecraft 4D story from 2017.

The global, multi-year partnership will grant Incase access to 20 Carbon M2 3D printers, the latest Carbon software, and the exclusive right to co-brand protective products for mobiles that are 3D printed using Carbon’s Digital Light Synthesis (DLS) technology.

Changing the material and design of mobile device protectors

Carbon’s DLS 3D manufacturing process is enabled by its proprietary CLIP technology, which uses DLS, oxygen permeable optics, and programmable liquid resins.

As part of the partnership, Incase will utilize this process to create what it describes as “the industry’s first 3D-manufactured protective mobile solutions designed with complex structures with in new elastomers at scale”

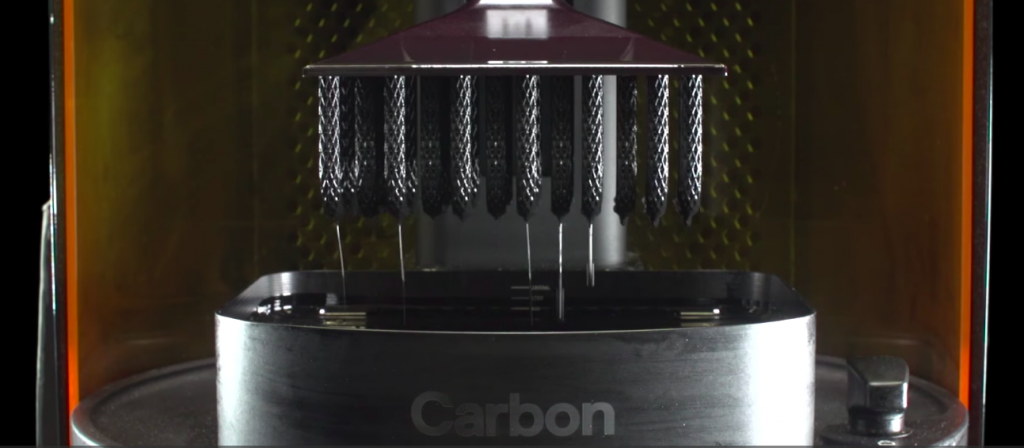

After 3D printing the protective cover designs with Carbon’s UV-curable polyurethane resin, the object will be cured to form a semi-rigid lattice structure, with a material composition that maximizes impact and drop protection, all within the lightest frame possible.

The partnership as means to simplifying the supply chain

With access to Carbon materials and hardware, Incase will have the capabilities to design, test and adjust designs incorporating structures rapidly and with more options than previously possible.

“In addition to redefining device protection from a material level, our partnership with Carbon significantly changes the mobility space operationally,” said Incase CEO Andy Fathollahi, “delivering benefits such as faster go-to market strategies, on-demand supply chain simplification, reduced tooling and prototyping stages and customization opportunities for our customers.”

For Incase, mass-customization and an on-demand inventory are now available in a shorter period of time thanks to Carbon’s proprietary Speedcell system, which connects the M2 3D printer to a Carbon Smart Part Washer.

“We are unlocking a new era in design and manufacturing, enabling designers and engineers to create previously impossible products and open up entirely new business models,”

added Carbon co-founder Phil DeSimone. “We are very excited to partner with Incase, fundamentally changing how device protection is designed, engineered, made, and delivered.”

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections now.

For more stories about company partnerships, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows a prototype 3D printed mobile device using Carbon technology. Image via Incase.