Impossible Objects has announced its pilot 3D printing machine, the Model One during the RAPID + TCT 2017 conference in Pittsburgh. The Chicago based company has been perfecting its composite-based additive manufacturing method (CBAM) for several years and will now release its first 3D printer machine with this technology.

According to Impossible Objects, the three main benefits of the technology are stronger parts, access to high quality materials and speed of production. Robert Swartz, chairman and founder of Impossible Objects explains,

Until now, there was no way to print functional parts with the mechanical and material properties at the scale these companies need. The Model One is just the beginning of what CBAM can do. Our CBAM technology has the potential to transform manufacturing as we know it.

3D Printing Industry is reporting live from Pittsburgh at the RAPID + TCT conference which this year features over 300 exhibitors displaying the latest 3D printing technology.

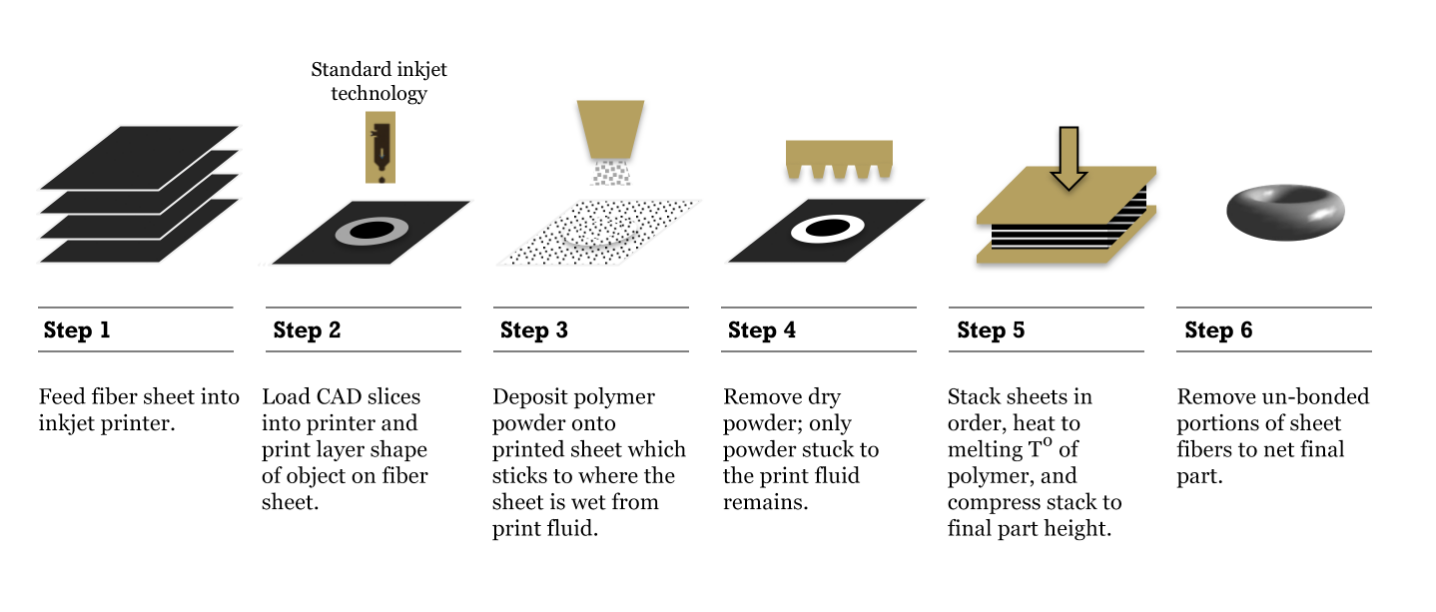

Gif shows the CBAM process in action. Images via Impossible Objects.

How CBAM technology works

Impossible Object regards its unique CBAM technology as “the first truly new 3D printing process in more than 20 years.”

The process uses “conventional thermal inkjet heads” to print a design onto sheets of composite materials like carbon fiber, Kevlar of fiberglass. Following this, the sheets are flooded with a polymer powder, “such as nylon or PEEK, causing the powder to stick where inkjet fluid has been deposited on the sheets.”

Once excess powder is removed with a vacuum, the sheets are stacked, compressed and heated in a furnace. This binds the polymer powder together and melts the sheets to form one solid object. Uncoated fibers are then removed with chemicals or mechanically and the user is left with “an exceptionally durable, lightweight object that was previously impossible to make so quickly and inexpensively.”

Stronger parts

According to Impossible Objects, 3D printed parts produced using the CBAM process can be up to 10 times stronger. Additionally the parts produced by CBAM are also lightweight in nature.

Range of materials

Impossible Objects state that the wide range of materials compatible with the device is another benefit of CBAM. The company states that it, “enables companies to build truly functional parts, from high performance materials such as PEEK and carbon fiber.”

In addition, due to the use of composites, Impossible Objects believe printed parts will be flexible in their application. Functionality is one of the main selling points of the machine as Impossible Objects state,

The Model One is designed to 3D print functional parts, at scale, using the widest selection of materials.

Speed

Impossible Objects state that the CBAM technology “has the potential to enable companies to build vital parts at production speeds 100x faster than current methods.” The company believes also that due to the functionality of the parts produced, the machine could be used to produce both a prototype and the final product.

Chairman and founder, Robert Swartz, echoes this as he says,

We’ve seen tremendous interest from a range of companies who want the advantages of 3D printing for their high-volume manufacturing and for materials they cannot get elsewhere,

Availability

The Model One machine will roll out to select Fortune 500 companies before it is available to the general public in early 2018. One of the pilot program partners is Jabil. The international manufacturing company was also the first company in North America to receive HP’s Jet Fusion 4200.

Greg Ojeda, senior director of AM Ecosystem Development and Strategy at Jabil said, “we believe Impossible Objects’ CBAM could become an enabling technology for high-volume manufacturing.” Before adding,

We’ve identified applications where Impossible Objects could deliver a competitive advantage and significant cost savings over conventional manufacturing processes. We are excited to take part in Impossible Objects’ pilot program and look forward to working with the Impossible Objects’ team.

3D Printing Industry also recently heard from Jabil’s Director of Digital Manufacturing, Rush LaSelle, on his thoughts on 3D Printing: The Next Five Years.

Specifications

Build Speed – 45 cubic inches per hour or greater

Build Volume – At least 384 cubic inches (12 x 8 x 4*) and up to 768 cubic inches (12 x 16 x 4*)

*Print height is not limited by the machine; taller heights are possible.

Layer Height – 0.0016 in (40 μm) to 0.002 in (50 μm) depending on fiber selection

X/Y print resolution – 600 dpi / 42 μm

The 3D Printing Industry Awards will be taking place this month in London and voting is still open to decide the winners.

For the latest 3D printer news, subscribe to our newsletter and follow us on twitter.

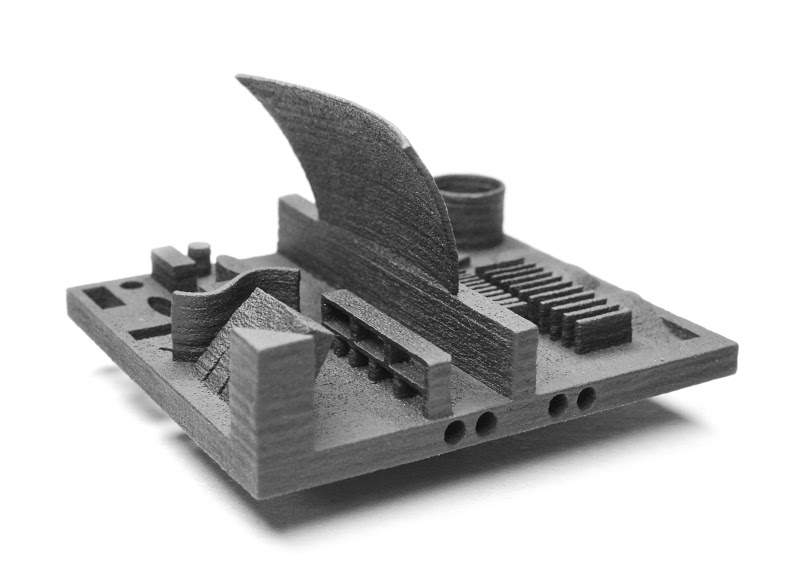

Featured image shows the Model One machine. Image via Impossible Objects.