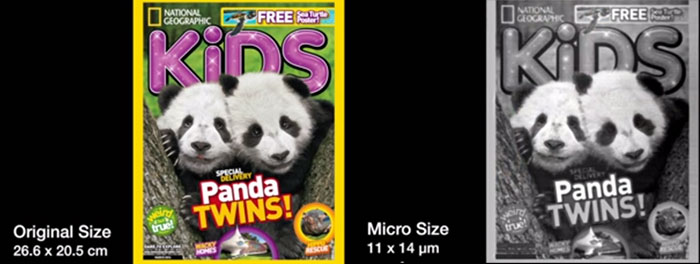

While it’s not technically 3D printing rather 3D carving, it’s still a pretty amazing advancement. IBM developed a nano scale process that is capable of chiselling a 3-dimensional pattern into pliable polymer as small as ten nanometers wide — that’s small enough to ‘print’ out the entire text of a novel on something the size of the period in this sentence.

As stated, tech giant IBM developed the process, however Zurich startup SwissLitho AG has licensed it and commercialised it as the NanoFrazor.The name is a play on words: Nano obviously needs no explanation, while ‘Frazor’ combines the German word for milling machine, “frase” with the English word “razor”. The Swiss are good at tech. The Swiss are good at chocolate. Puns, maybe not so much.

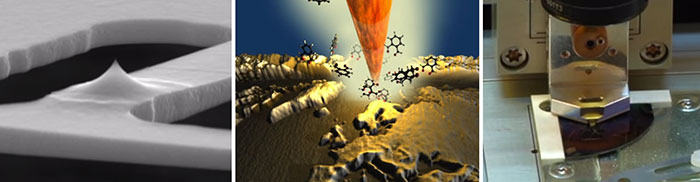

“The NanoFrazor is great for rapid prototyping all sorts of applications,” IBM’s Colin Rawlings explained. “It runs open loop in order to achieve scan speeds of millimeters per second and uses a specialized heated tip, mounted on a bendable cantilever, that is 700 nanometers long, but just 10 nanometers in radius at its tip.”

The NanoFrazor works by using its small heated nano chisel to chip away patterns in the surface of a polymer base. You can then confirm the pattern that you just printed by running the chisel tip along the pattern once it’s cooled. This pattern reading has a sub-nanometer accuracy rate, and can be inspected immediately, unlike traditional nanoprinting methods.

The most obvious use for this technology would be in the creation of microchips and microprocessors. Typically an electron beam would be used, however e-beams are generally limited to 2 dimensional patterns. Additionally, the NanoFrazor is considerably less expensive, coming in at “only” $500,000 in comparison to the $1.5 million price tag of e-beams. And that’s just the starting price. IBM is also looking into using the machine to aid in quantum computing by creating 3D patterns that can help reduce light and data scattering problems common in microscopic computing structures.

You can learn more about the NanoFrazor here. And here’s a video of the nano 3D printer in action.