During the recent conference on AM that took place at the EMO International Manufacturing show in Milan (more on that later this week), many industry leaders offered their take on the state of the industry. Among talks from representative of Avio Aero (GE), COMAU, ISO, EOS, CECIMO, and more, I found one new technology particularly interesting: the AMBIT system by Texas-based HYBRID Manufacturing Technologies, which can transform any industrial CNC machine into a hybrid system with additive manufacturing (laser cladding) capabilities. How the additive part works is similar to Sciaky’s EBAM technology, except that it uses a laser instead of Sciaky’s electron beam, a type of fused deposition that uses a metallic filament.

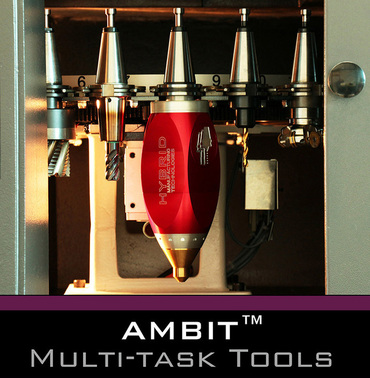

The AMBIT multi-task system, developed by Hybrid Manufacturing Technologies, is an award-winning, patent-pending series of heads and docking systems that allows virtually any CNC machine (or robotic platform) to use non-traditional processing heads in the spindle and conveniently change between them. Changeover (as can be seen in the video below) is completely automated and only takes seconds.

As the company’s founder and CEO, Jason Jones, explained to me, “Hybrid Manufacturing Technologies is dedicated to combining complementary technologies – including CNC milling, Additive Manufacturing/3D printing – along with in-process part inspection.” Hybrid Manufacturing Technologies was founded in 2012 by Dr. Jason Jones and Peter Coates as a spin-off from a collaborative research and development project. The company’s philosophy builds on the fact that, for the last decade, the CNC world has largely been an idle spectator to the advancements in Additive Manufacturing (AM) systems for metals.

And yet, for many aspects, CNC mills have superior production rates and do not require post-machining like AM parts often do. Furthermore, the cost of metal AM systems can be difficult to justify, even for high performance components. “To end this historic feud between additive and subtractive technologies, hybrid machine tools, equipped for both CNC and AM, enable the use of both technologies in optimal proportions as needed,” says Jones. AMBIT is the commercial result of a 4-year UK-based research project named RECLAIM (REmanufacture of high value products using a Combined Laser cladding, Inspection and Machining system) which focused on offering a complete and integrated solutions for many different aspects of the manufacturing and repair process.

In a way, desktop 3D printers have been leading the way, offering multifunctional solutions from the Fabtotum to the ZMorph, WASP, and Open Beam for quite some time now. Of course, seeing an advanced manufacturing robot do hybrid additive and subtractive manufacturing in a completely automated manner is quite a different story, and one we will definitely keep writing about.