Leading German chemicals company Henkel, has announced a partnership with SYMPA, a research and development project advancing new materials and stereolithography (SLA) processes for the automotive sector.

SYMPA is sponsored by the German Federal Ministry of Education and Research (BMBF) and the Federal Ministry Republic of Austria Transport, Innovation and Technology (BMVIT), and includes the Institute of Aircraft Design (IFB), Rapid Shape, Cirp, and Joanneum Research.

SYMPA and SLA

Commencing in 2018, the “Stereolithography materials, production and plasma-post-processing for durable automotive applications” project, otherwise known as SYMPA, aims to address the low mechanical properties, low durability and low UV stability of SLA materials.

Therefore, the partners are seeking to develop a new photosensitive polymer with increased long-term thermal and mechanical properties. Moreover, a fibre reinforcement of the polymer and surface modification technologies are being developed to further enhance the environmental resistance of automotive products.

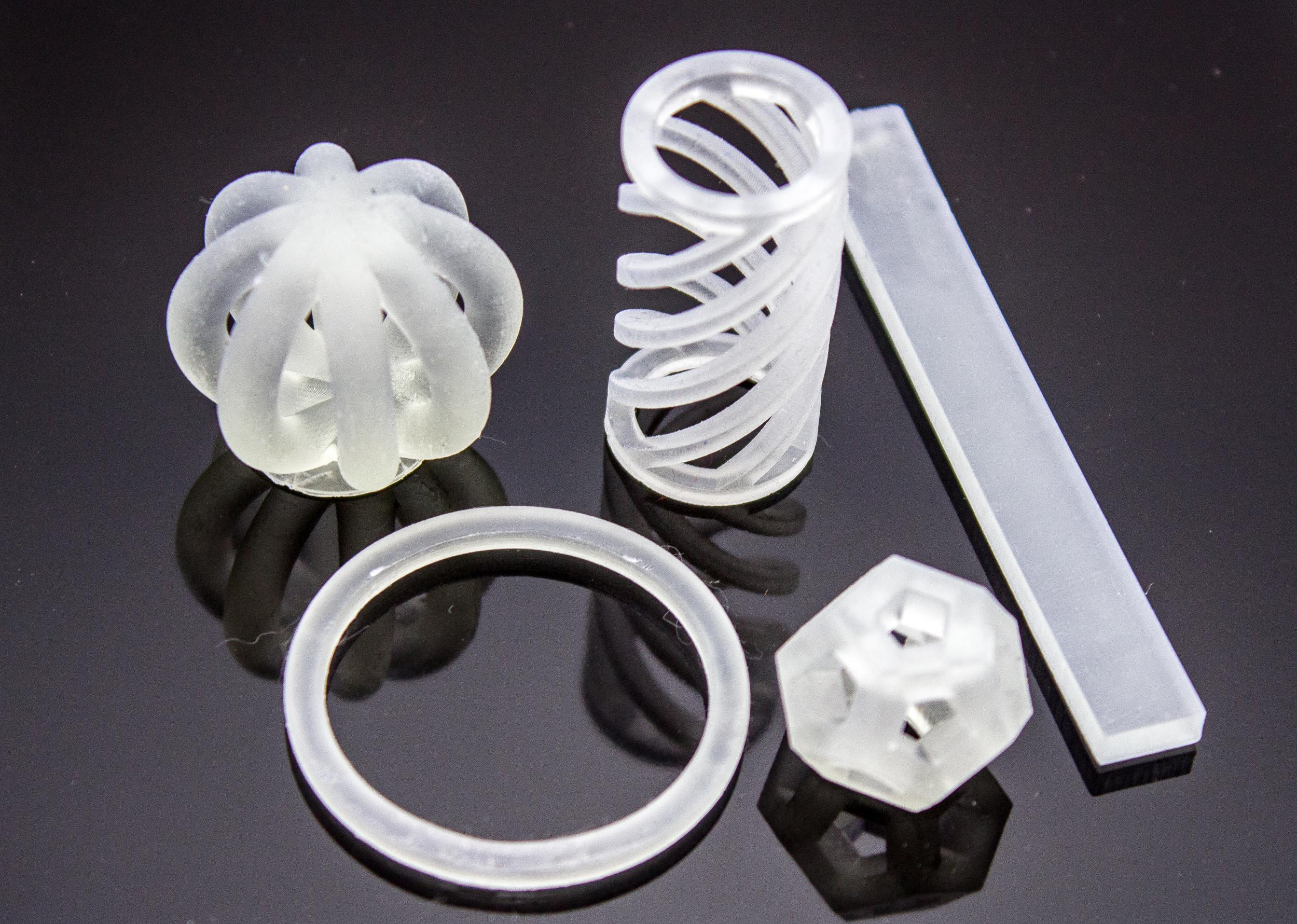

In its role, Henkel, which recently joined silicon valley 3D printing startup Origin’s Open Material Network, has developed novel high-performance photopolymers with improved mechanical and thermal durability for the SLA technology.

The SYMPA consortium

The initial partners are also approaching this project from their respective specialist areas. IFB, a part of the University of Stuttgart, is extending its knowledge in lightweight construction and composite applications to develop fibre reinforced SLA materials with strongly increased mechanical properties and fatigue limit.

Rapid Shape, a Digital Light Processing (DLP) 3D printer manufacturer, is offering its hardware, including the Studio-Line HA20 II, HA30 II and HA40 II, for high speed open additive manufacturing, to meet various material, customer, and environmental conditions.

Joanneum Research, one of Austria’s largest non-university research organisations, are specialists for the development and application of plasma technology for coating and activation. Thus, this institution will focus on material deposition, post-processing and surface modification for improved mechanical and environmental resistance. The controlled wettability and electric conductivity of polymers are also being explored.

Finally, German rapid prototyping company, Cirp, is enabling technology demonstrations on real automotive structures and improved design processes of SLA components.

SYMPA is scheduled for completion in 2021 and will result in the development of an SLA toolbox for tailored 3D printing solutions in the automotive industry.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a selection of 3D printed objects using Henkel-developed resin. Photo via Henkel.