Raise3D’s “Go Green Initiative” focuses on utilizing best practices to minimize environmental harm.

Raise3D, a global additive manufacturing solutions provider, has announced its “Go Green Initiative.” Being green by nature, in the opinion of Raise3D, is the finest strategy. According to Raise 3D, a circular economy and sustainable practices can be facilitated by 3D printing. Examples include sustainable materials like PLA and the inherent waste reduction of additive manufacturing. Firstly, the plastic spools for 3D printing filament used by Raise3D will be replaced by cardboard. These cardboard spools will feature on 6 Premium Filaments: PLA, ABS, ASA, PETG, PC, and TPU-95A. The spool was created to ensure that the printing process quality and dependability remained unaltered and employ adhesives that can endure even the high temperatures of filament drying treatments. Secondly, the firm aims to utilize recycled cardboard boxes that are easy to dispose of and recycle again.

“While there are still many challenges to get there, the innovative process sometimes surprises us with relevant leaps forward, and so we shall hope the dream will one day become a reality, even if it may take one or two decades,” said Diogo Quental, coordinator of Raise3D’s Go Green Initiative. “In the meantime, it’s our responsibility to implement all the actions that are possible already, and we are committed to doing so. We want to make 3DP always look greener on our side.”

Green initiatives in 3D printing

“The vision we all have is to have ocean’s plastic pollution transformed into filament we can use in 3D Printing, contributing to a circular economy,” said the coordinator of Raise3D’s Go Green Initiative.

The circular economy is a theory that aims to utilize resources as efficiently as possible to reduce waste. Sustainability announcements from 3D printing companies show a focus on eco-friendly materials, creative ways to reuse waste, and the beginning of new projects aiming to lessen the environmental impact of additive manufacturing. One example of material innovation is an eco-friendly, recyclable resin created by researchers from Vilnius University and the Kaunas University of Technology in Lithuania.

Aiming to gain insight into circularity within the 3D printing industry and where opportunities exist for circular economy processes to be applied within the sector moving forward, 3D Printing Industry has spoken with experts, including Emma Fromberg, course director at the Cambridge Institute for Sustainability Leadership, and Marta Redrado Notivoli, project coordinator of EU-funded research initiative BARBARA and chemical engineer at the Aitiip Technology Center.

Elsewhere, a report by the German environmental association, Umweltbundesamt (UBA), explains the pros and cons of additive manufacturing and how it impacts personal health at home and in industrial areas. This research has examined the text of 987 studies on 3D printing, considering the many components of 3D printing, including materials, technology, and industrial supporting services. The study sought to detect present and emerging trends in environmental effects using a qualitative content analysis tool.

Raise3D’s recyclable filaments

3D Printlife Pro PLA – E2/ Pro2 Series

3D Printlife PLAyPHAb™ – E2/ Pro2 Series

3D Printlife Enviro ABS™ – E2/ Pro2 Series

3D Printlife OMNI™ – E2/ Pro2 Series

3D Printlife ALGA™ – E2/ Pro2 Series

3D Printlife YOGA·Flex – E2/ Pro2 Series

Covestro Addigy® F1030 CF10 – E2CF

FILAMENTS.CA Easy PC CPE – E2/ Pro2 Series

Polymaker PolyFlex™ TPU95 – E2/ Pro2 Series/ N Series

Polymaker PolyLite™ PLA – E2/ Pro2 Series/ N Series

Polymaker PolyLite™ ASA – E2/ Pro2 Series

Polymaker PolyLite™ PETG – E2/ Pro2 Series

Polymaker PolySupport™ – E2/ Pro2 Series/ N Series

Polymaker PolyMax™ PC – E2/ Pro2 Series/ N Series

Polymaker PolyWood™ – E2/ Pro2 Series

Polymaker PolyMax™ PLA – E2

Polymaker PolyTerra™ PLA – E2

Polymaker PolySmooth™ – E2

Nominations for the 3D Printing Industry Awards 2022 have now commenced. Nominate now, the form closes at the end of the month. Who do you think should make it to the shortlists for this year’s show?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

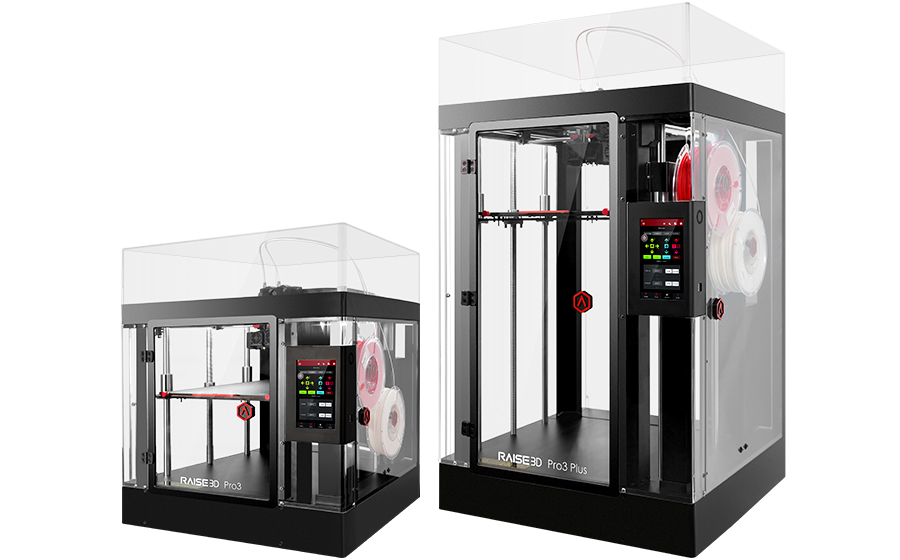

Featured image shows the RaiseFactory systems. Image via Raise3D.