One of the most useful, immediate and concrete applications of desktop 3D printers is the production of small components for industrial machines and as a mean to complement a specific type of industrial production. Leapfrog, one of the most successful manufacturers of desktop 3D printers in Holland, comes from the flexographic industry. Gimax3D, a company based in Prato, Italy, was born as a branch of TAIP Automation, a company that operates in the manufacturing of special and custom water heating solutions.

Just like Leapfrog, the company decided to use its expertise to create a desktop 3D printer that would meet their own requirements, specifically to be able to cater to a young company that develops innovative solutions and has been diversifying its production by getting into the automotive, electrical refrigeration and robotic packaging fields. An affordable 3D printer that can work for them can work for just about any maker and small company out there so, last March, they launched their Gimax3D Standard 1:0 and now they are launching the new Standard 2.0 evolution model for more professional users.

Weighing in at 78 Kg, with 90 cm width and 120 cm height, it is hardly a desktop system as much as a professional tool for small companies such as TAIP itself. The main feature of the Standard 2.0 is the build volume, which was expanded up to a significant 400x400x400 mm (with a 25 liter build volume). The machine is CE certified and has a solid aluminum body, with a wider heated plate and the print speed up to 200 m/s, which is pretty fast for a desktop FDM machine.

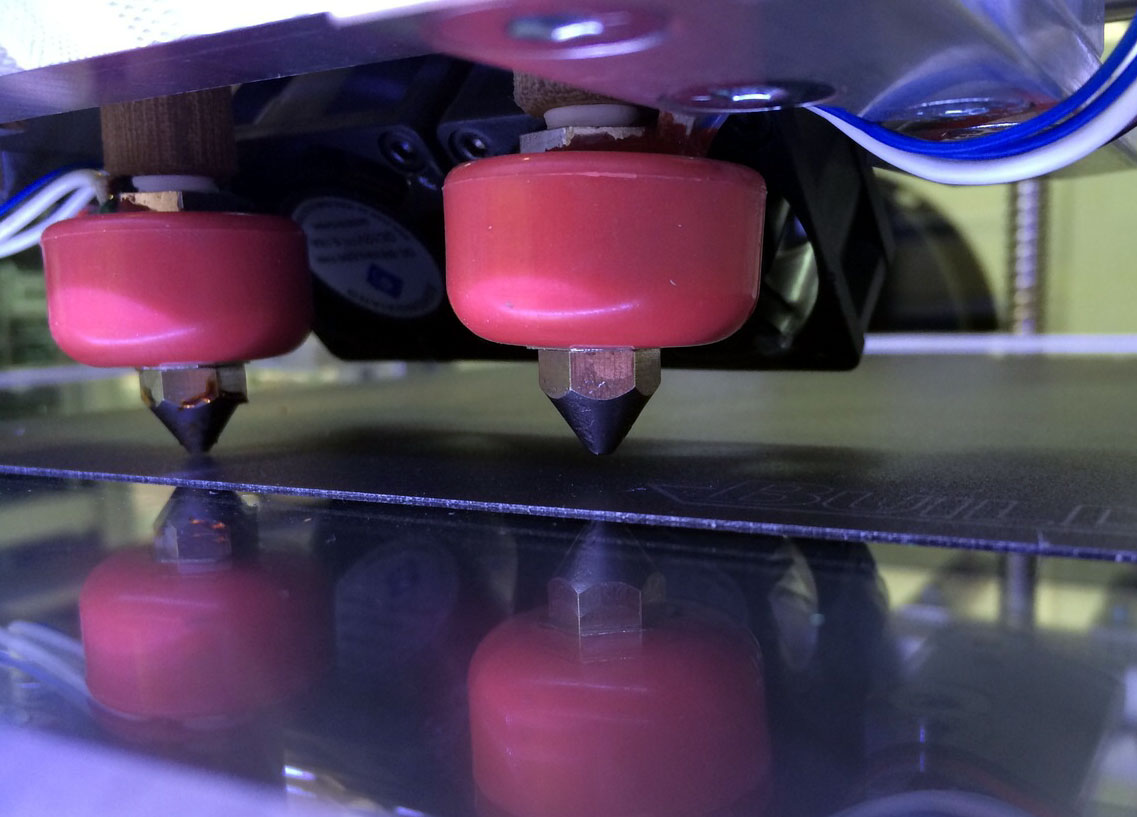

It can print with a wide range of materials including ABS, PLA, nylon, HIPS, rubber and specialty filament (with 1.75 mm diameter) through its double extruder, with nozzle size ranging from 200 to 800 micron and maximum layer resolution of 60 microns. All prints can be launched and managed from the SD card and the on-board LCD screen.

Prato, where TAIP and Gimax3D are based is one of the most industrial areas of central Italy and, as much as the traditional Italian industry has been suffering a crisis unlike any since World War II, many of the local companies are struggling. The only way out is reducing costs, optimizing production and speeding up the prototyping phase. This is exactly what a 3D printer can offer and if they are able to effectively convey their message, the Gimax3D Standard 2.0 will be a feasible solution.