GH Induction, an expert in induction heating systems, has formally introduced a new service organization revolving around 3D printed inductors. The new service, named SERVINDUCTORS, aims to help customers of the Valencia-headquartered company transition from conventional to 3D printed coils, saving on various costs.

Induction systems

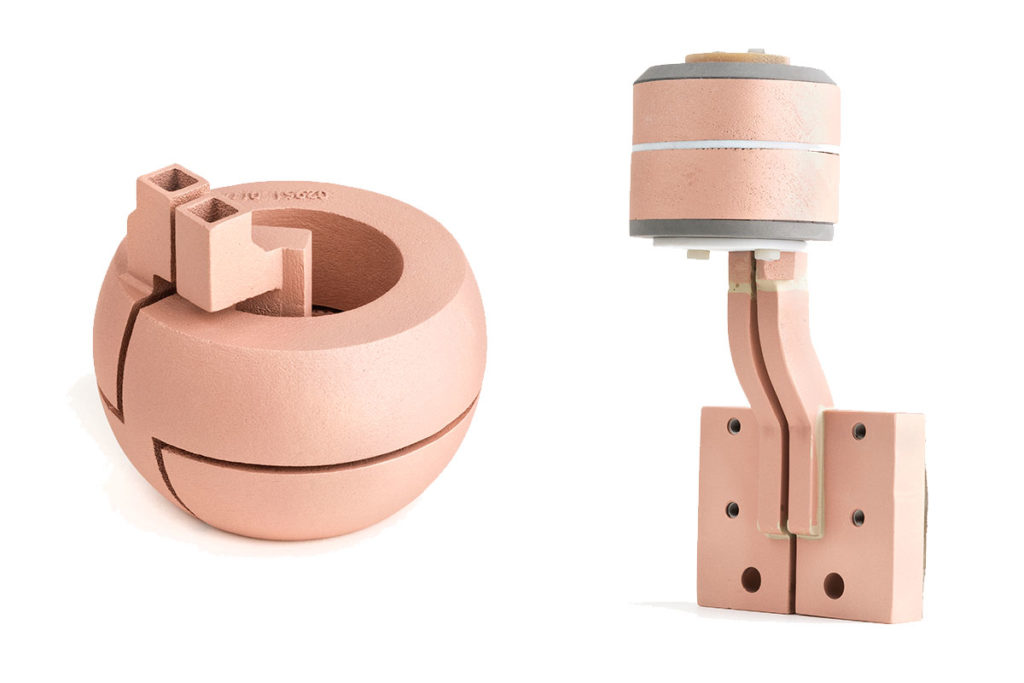

Induction heating is often used in the heat treatment of metals, whereby an AC current is run through copper coils to induce heat in ferrous metal. Inductors are also common components in AC electronic equipment such as radios and speakers. They are metallic coils that block AC while letting DC pass in an induction system. Inductors are regarded as a consumable part and therefore make up a large portion of the maintenance costs associated with induction systems. A service providing extensive monitoring and preventive actions could reduce these costs significantly while extending component life.

The SERVINDUCTORS service

The new service will run alongside GH’s standard services and gives clients access to a specialized consultant. Clients have the option to raise doubts, ask about problems and potential improvements; they are given access to improved purchasing conditions and can update their current inductors to new 3D printed coils provided by GH.

The service comprises four main areas. The commercial area is responsible for customer satisfaction, the applications area develops and monitors inductor versions with its own laboratory. The production area controls the service life of each inductor and the quality area records parameters for traceability and sets quality protocols for continuous improvement.

The service aims to launch GH Induction to pole position as a supplier in the induction market, starting with Spain and Portugal. The service will soon be extended to the rest of the countries where the company operates.

3D printing copper coils for induction applications is an area where activity is increasing. TRUMPF, a German provider of machine tools, recently demonstrated the capabilities of its green laser technology in fabricating copper structures for use in heat exchangers and conductive inductors. Elsewhere, in the US, metal 3D printer provider Markforged released a pure copper material option for use with its Metal X 3D printer. The move is expected to have major implications in the electronics industry as manufacturers now have the option to 3D print their essential inductors.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed copper inductor. Photo via GH Induction.