A team from GE Research’s cutting-edge Forge Lab has developed a super-secure blockchain network for additive manufacturing. Designed to manage and protect 3D printing transactions from powder supply through to the finished product, this system encrypts data in a way that promises to withstand attack by quantum computers.

Benjamin Beckmann, Blockchain Leader at GE Research, explains, “The demonstration of Blockchain for Additive is an excellent use case to build out our blockchain framework.”

“We can create networks that allow for fine-grain control of materials flows, data, intellectual property and identity along the entire additive digital thread. The goal here is to provide security for the entire additive process from powder to print.”

Secured from powder to part

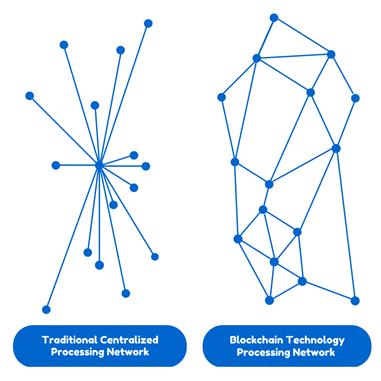

As a digital process, taking advantage of Cloud capabilities, production-ready 3D printing requires in-built security systems. Blockchain is an effective method of instilling security across all stages of the 3D printing process, as the records it maintains about each step is distributed across a vast network making it difficult to access or alter in any way.

Especially pertinent for the aerospace and defense industry the U.S. Armed Forces, including the Army Research Laboratory (ARL) and Department of the Navy, have developed proprietary blockchain encryption for their 3D printing initiatives. Private companies, including Link3D, Wipro and Moog have also developed specialist blockchain solutions for the technology.

At GE, blockchain technology for additive manufacturing is years in the making.

Quantum-secure blockchain protection

In June 2018 a blockchain patent assigned to GE was published under the inventors John Freer, Richard Messmer, Arvind Rangarajan and David Safford. Still to be granted by the U.S. Patent Office, this document details “An additive manufacturing device configured to implement a distributed ledger system” consisting of hardware, software controller, and various steps for build validation.

The latest GE Blockchain Network has, in contrast, been developed by Beckmann and colleagues Principle Engineer John Carbone. Explaining the new quantum-secure system, Carbone says, “In the network, each identity associated with devices, designs, machines, materials, components and people can be quickly verified, qualified, documented and managed in an automated fashion with the highest degree of data integrity and assurance.”

In addition, “The system is based on modern cryptographic methods focused on data integrity, data ownership and rights plus automated workflow capabilities through distributed ledger technologies for contracts and transactions.”

Full details and further results of this development are to be presented Beckmann at the 2019 CONSENSUS Blockchain Conference in New York City from May 13th to the 15th.

For all the latest 3D printing security news subscribe to the daily 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Vote for your 2019 Innovations of the Year in the 3D Printing Industry Awards.

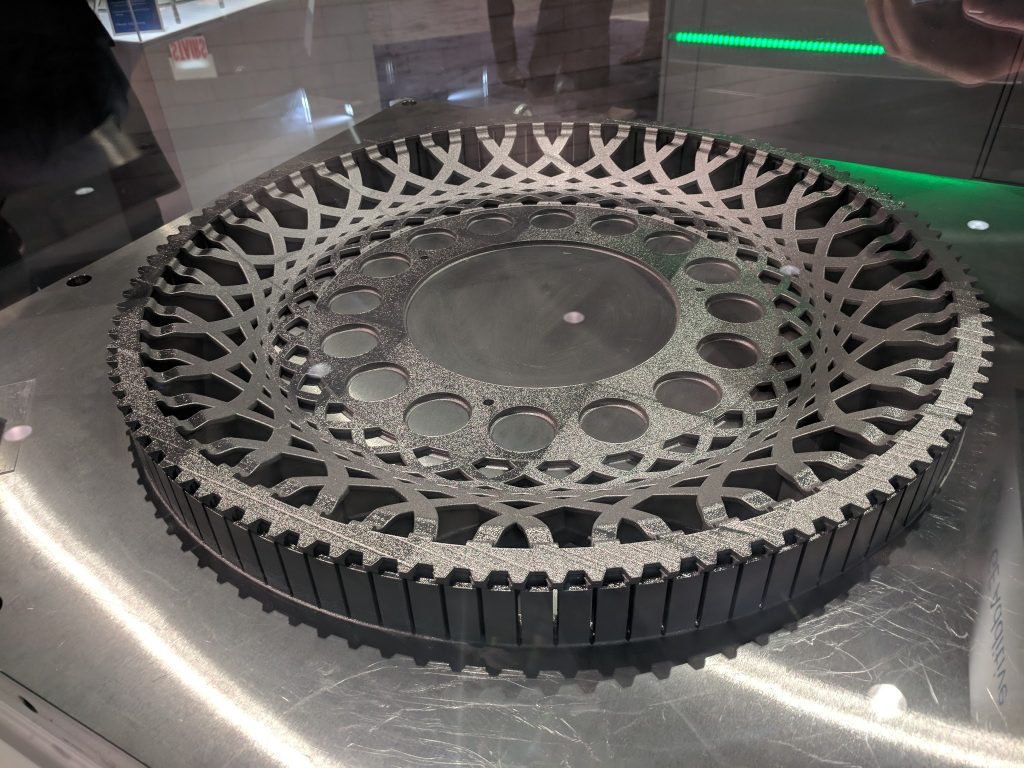

Featured image shows metal additive manufacturing at GE. Photo via GE Research