FIT Additive Manufacturing Group, a German 3D printing service provider, has developed novel aerospace components in collaboration with Turkish Aerospace Industries (TAI), ArianeGroup, and HAUNI Group.

The company also announced its commitment to accelerating additive manufacturing through a recent investment. Carl Fruth, CEO at FIT AG, stated: “During the past 12 months we have, again, invested a multimillion EUR to continue to keep the pole position in the development and manufacturing of highly innovative AM components.”

Additive manufacturing and aerospace

Debuting at Formnext 2019, FIT AG’s selection of aviation applications included a 3D printed rocket engine fluid manifolds created in partnership with ArianeGroup, formerly known as Airbus Safran Launchers. The components are designed for the Ariane 6, a modular, launch system, and will be developed using Wire Arc Additive Manufacturing (WAAM). The aim of such parts is to achieve production costs 40 to 50% lower than the Ariane 5.

Furthermore, with support from TAI, FIT has developed a 3D printed star tracker bracket capable of holding an optical controlling device which steers the exact position of a satellite in orbit. As stated by FIT AG, a conventional bracket comprises of 360 individual parts. The partners state that the 3D printed star tracker bracket led to a significant reduction of component complexity as well as a weight reduction of 50%.

Additive manufacturing is also being explored by the partners as an alternative to copper injection molding as well as a solution for the high economic production costs of metal parts.

FIT Additive Manufacturing Group

Earlier this year, FIT AG acquired a Hot Isostatic Pressing (HIP) machine from Quintus Technologies, a Swedish high-pressure technology expert. This machine will ensure that after post-processing, 3D printed metal parts pass the quality assurance tests as smoothly as possible.

Prior to this, the company announced the founding of its newest subsidiary, FIT Japan KK which aims to expand FIT AG’s operations and customer base within Asia’s developing additive manufacturing market. In 2017, FIT AG also purchased five EOS M 400-4 systems to expand its production capacities.

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the 3D printing industry? Visit 3D Printing Jobs to commence your career in additive manufacturing.

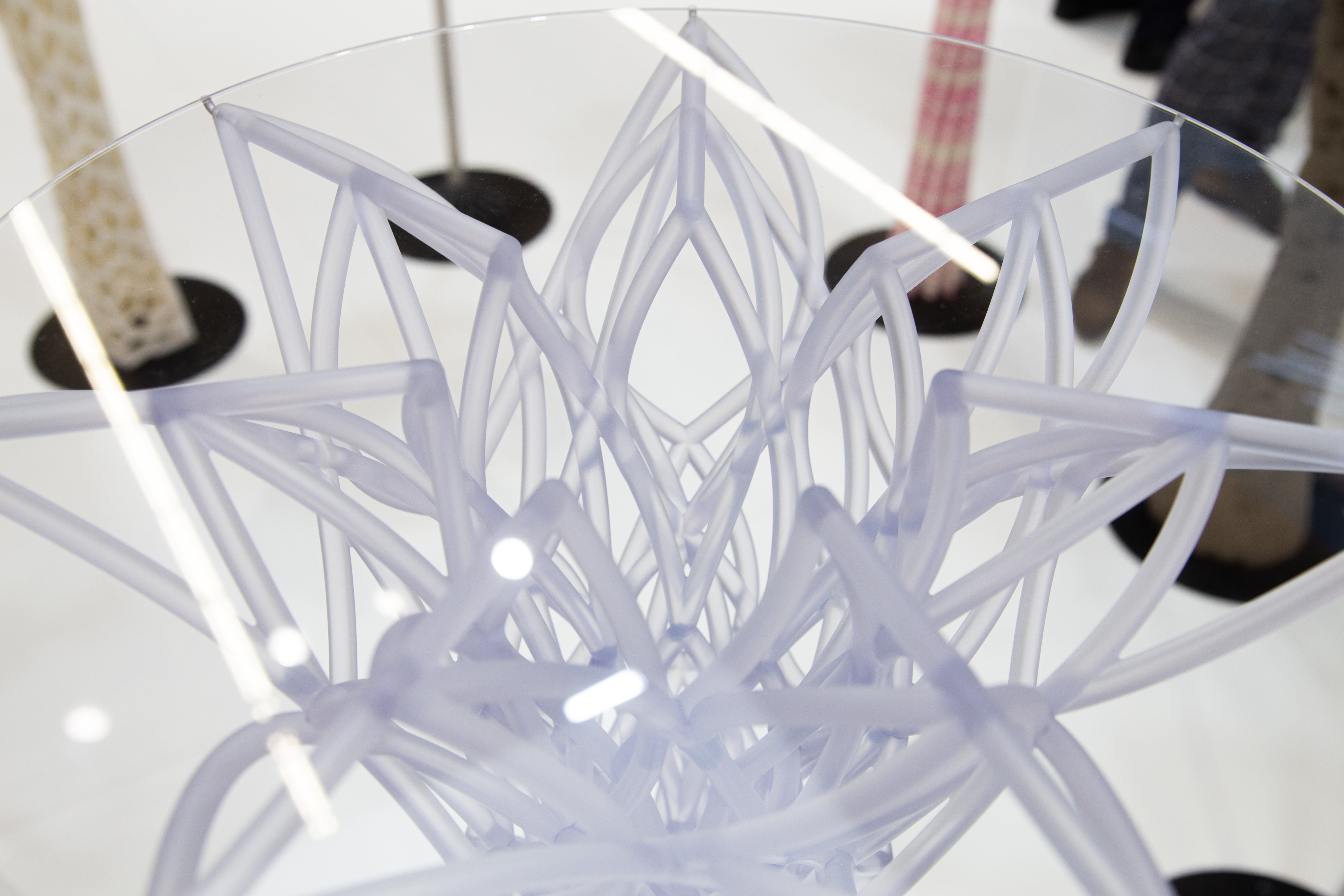

Featured image shows the FIT booth at Formnext 2019. Photo via FIT AG.