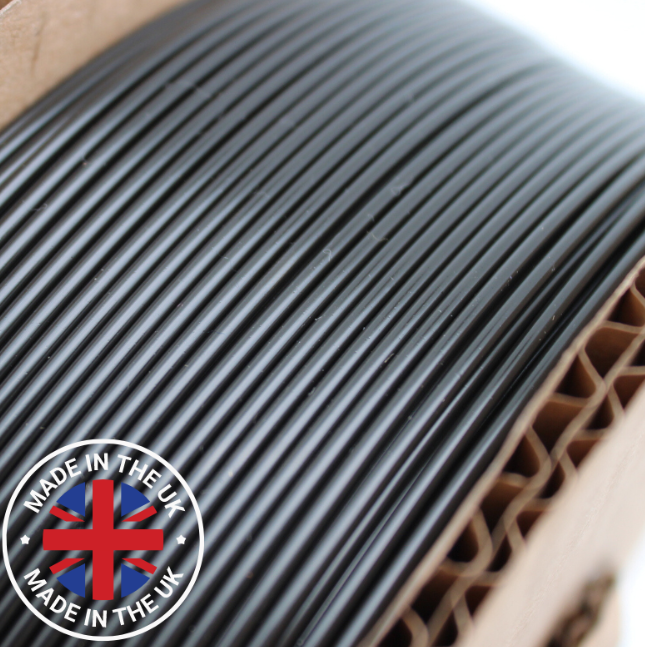

UK-based 3D printing filament manufacturer Filamentive has launched its latest product, Economy PLA.

This recently introduced filament is made with a high percentage, up to 99.99%, of recycled materials, establishing it as a “potentially eco-friendly option” in the 3D printing filament market. Economy PLA is currently available in black and white colors and can be conveniently purchased from Filamentive’s website or authorized retailers.

“We are dedicated to sustainability and consistently seek ways to minimize our environmental footprint. The launch of Economy PLA is a significant step in this direction. We believe this product will resonate with customers seeking both sustainability and high-quality 3D printing filament,” said Ravi Toor, Managing Director, Filamentive.

Filamentive provides sustainable filament range

A notable characteristic of Economy PLA is its composition, which is derived from post-industrial waste. This means that it utilizes materials that have been diverted from the waste stream during the manufacturing process. By using this single-source waste, the filament is able to remain free from debris, reducing the likelihood of contamination. Additionally, Economy PLA maintains the same level of quality and performance as other filaments offered by Filamentive. The filament is available in 1kg spools.

The introduction of Economy PLA marks significant progress in the 3D printing sector, as it is among the early filaments to be manufactured using a substantial amount of recycled material. This characteristic potentially positions it as a more sustainable alternative compared to conventional filaments, which primarily rely on new plastic materials. Filamentive believes the introduction of Economy PLA “sets a good example” for other companies in the industry, encouraging them to focus on environmental responsibility when developing their own products.

Initially, Filamentive also launched PLA Tough filament which helped the company “inch closer towards sustainability.” The material utilized in the production of this filament is derived from renewable resources, specifically sugarcane. It possesses the property of biodegradability, enabling it to naturally decompose through the action of microorganisms in the environment. The filament is packaged on 100% recyclable cardboard spools, aligning with sustainable packaging practices. Notably, it is designed to offer user-friendly printing experiences, even for individuals new to 3D printing. Additionally, the filament exhibits strength and durability, making it suitable for various applications that require robust materials.

3D printing acing the sustainability game

Filaret, a company that developed sustainable 3D printing materials, collaborated with Estonian authorities to tackle the issue of discarded cigarettes on the country’s beaches. In cooperation with the local government in Tallinn, a proactive initiative was launched to install designated litter bins along specific beaches, encouraging the public to responsibly dispose of cigarette butts. Filaret had planned to retrieve the collected waste from these bins and transform it into a novel sustainable filament suitable for composting, thereby promoting sustainable practices in the realm of 3D printing.

Braskem, a Brazilian petrochemical company, unveiled its first collection of eco-friendly 3D printing filaments. These filaments, which are composed of bio-based ethylene vinyl acetate (EVA), recycled polyethylene (PE), and polypropylene (PP), represent a significant step towards sustainable manufacturing. Braskem showcased this novel materials at RAPID + TCT 2022, in Detriot. Jason Vagnozzi, Braskem’s Global Commercial Director of Additive Manufacturing, said, “Braskem has a longstanding history of innovating and producing more sustainable bio-based polymer 3D printing filaments reaffirms our commitment to a more circular, carbon neutral future.”

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Economy PLA is made using 95-99.9% recycled material. Image via Filamentive.