Chinese 3D printer manufacturer Farsoon Technologies has strengthened its strategic partnership with Siemens China, focusing on integrated industrial solutions for additive manufacturing.

This alliance aims to further enhance their long-standing relationship and jointly develop novel solutions for the AM sector. As part of the collaboration, Jack Cheng (Farsoon Board Member & Deputy General Manager) and Don Xu (Farsoon Board Member & Global Business Group Director) led a factory tour, highlighting Farsoon’s latest AM machines designed for large-scale series production. In subsequent discussions, Dr. Karsten Heuser, Vice President of Siemens Additive Manufacturing, engaged in detailed conversations with the Farsoon team regarding “pushing the boundaries of AM toward Industry 4.0.”

“Farsoon and Siemens have a long cooperation history. Our colleagues in U.S. and China both give many positive comments on Farsoon machine,” said Dr. Karsten Heuser, Vice President for Siemens Additive Manufacturing. “In the future, we will see an in-depth collaboration of both companies and more Siemens solutions integrated on Farsoon Machine.”

Expanding additive manufacturing capabilities

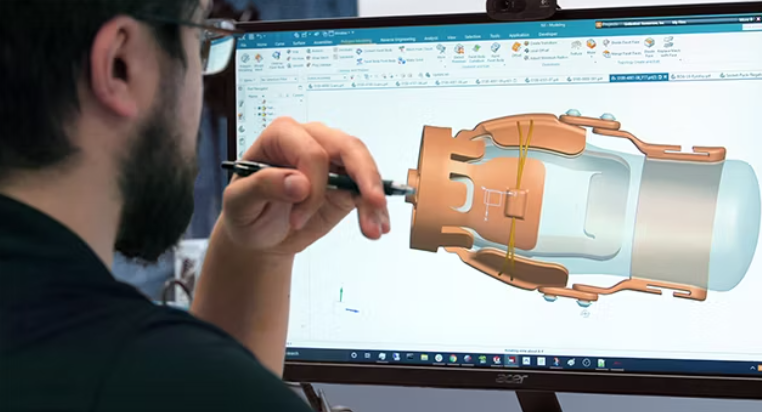

Under the terms of the partnership, Farsoon and Siemens will focus on several aspects. They will continue integrating Siemens NX software into Farsoon’s metal and plastic open platform AM systems aiming to provide comprehensive machine-software solutions for production-scale application projects. Both companies will collaborate to enhance the implementation of Siemens automation and drive solutions in Farsoon’s AM machines, prioritizing Siemens solutions in future machine development and production decisions.

Additionally, Siemens will provide Farsoon’s 3D printing users with efficient and high-performance factory automation solutions that simplify the “design-to-manufacture” process, leveraging their expertise in industrial digital manufacturing. Farsoon users will have access to Siemens Financial Services, which can offer customized purchasing solutions tailored to their budget requirements, ensuring easy access to the latest technology.

Moreover, Farsoon’s AM expertise allows for collaboration with Siemens on tailored machine solutions for aerospace, healthcare, automotive, and industry manufacturing applications.

“Siemens as an industry leader in automation and manufacturing software/hardware solutions is a key partner for Farsoon Technologies as we work to increase the adoption of additive technology in large-scale manufacturing applications,” added Dr. Xu Xiaoshu Founder and CEO of Farsoon. “As a long-term partner of Siemens, we are excited to increase the scope and pace of collaboration in future products and solutions and I look forward to a close collaboration between our two companies going forward.”

Additive manufacturing partnerships enhance operational capabilities

Additive manufacturing smart production cells developer Handddle extended its collaboration with the French Air and Space Force. The partnership aims to enhance the French forces’ operational capabilities by enabling them to effectively respond to unforeseen situations and quickly adapt to new circumstances. Following the successful installation of the initial Smart Farm micro factory at the French Air and Space Force‘s National 3D Printing Pole (PNI3D) last year, Handddle plans to introduce two additional installations. These micro factories provide an optimized environment for 3D printing and incorporate software that allows real-time control over the printer fleet.

Mark3D UK and Fieldmade, a spin-off of the Norwegian Defence Research Establishment (FFI) announced a strategic partnership agreement. According to the agreement, Mark3D UK will have exclusive distribution rights to supply Fieldmade’s Nomad LW portable 3D printers in the UK. This announcement signifies a notable change in the go-to-market approach for the Fieldmade Nomad LW range, which is based on Markforged technology, including servicing, supply, and support. Fieldmade CEO Jostein Olsen said, “Fieldmade AS are specialists in a number of primary areas, our products and services cover Digital Inventory Management, Consulting Services, and the Nomad range of in-field additive manufacturing equipment.”

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows From left to right: Vince Zhao (Farsoon Director of Business Development – AMEA region), Hong Wei Kang (Siemens Key account manager), Wei Cheng Wen (Siemens Business Development Manager), Dr. Xu Xiaoshu (Farsoon Founder & CEO), Dr. Karsten Heuser (Siemens Vice President of Additive Manufacturing), Jack Cheng (Farsoon board member & deputy general manager), Don Xu (Farsoon board member & Global Business Group Director), Bo Cheng Zhang (Siemens Head of Vertical Management AM), Wenyu Guo (Farsoon Metal Product Line Manager). Image via Farsoon Technologies.