The European Welding Federation (EWF) has launched the early stages of an International Additive Manufacturing Personnel Qualification System (IAMQS), publishing the details of the program in a whitepaper available online.

The qualification system, dubbed an “international first”, is designed to train and recognize technical professionals in the industry, in a bid to keep up with the evolving nature of the Additive Manufacturing landscape. The system has already been implemented in a number of European countries with plans to expand in the coming years.

Bridging qualification and recognition

Since 1992, the EWF has been working on ways to standardize training when it comes to welding technologies. The Federation was built on the premise that there is indeed a divide between qualification and recognition, whereby training on the job is not formally recognized but a University degree is, despite the former – in most cases – adding more value to a technical professional’s skill set. The EWF aims to bridge this divide, with the ultimate goal of providing a globally recognized qualification system to advance the technical capabilities of welding professionals.

The EWF has since implemented an extensive ISO/IEC 17024 compliant qualification system for traditional welding technologies, ensuring that the resultant qualifications are identical regardless of geography or institution. It is currently offered by 683 Authorised Training Bodies (ATBs) in 46 countries where the system is in use, with a network of 55,000 companies worldwide.

The AM qualification system

In line with the rise of additive manufacturing technology in the past decade, EWF leveraged its experience in the development of harmonized qualifications to launch an additive-specific international qualification system. The system was built in conjunction with industry experts, whereby the EWF first conducted market research to collect data on the current market’s skill needs.

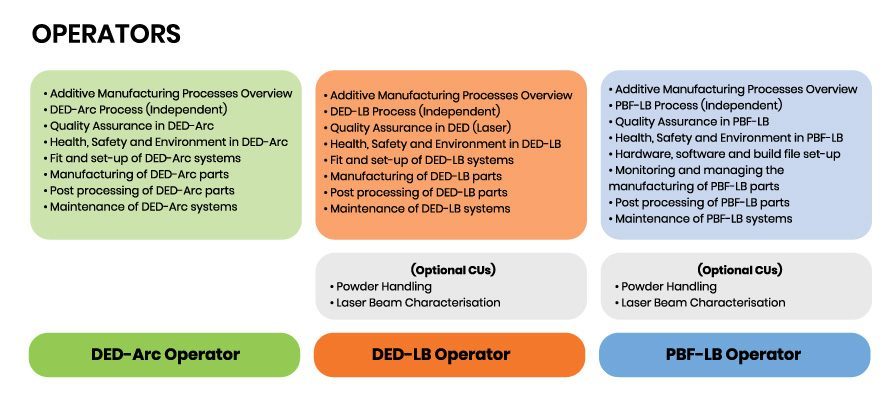

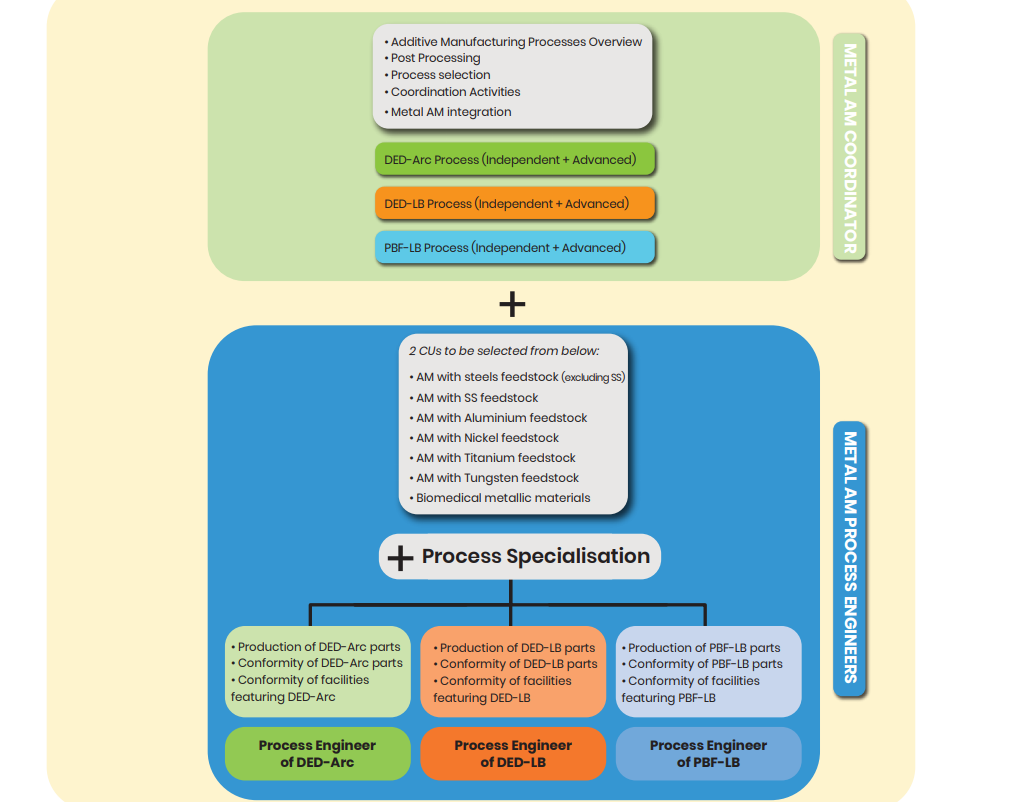

The EWF then carried out validation workshops with industry professionals and academics to develop qualification pathways for three different levels: Operators, Coordinators and Engineers. The qualification system itself features a modular structure, enabling a more flexible and individualized training curriculum.

As it stands, the EWF currently offers seven different qualifications in metal additive manufacturing – three ‘Metal AM Operator’ qualifications, one ‘Metal AM Coordinator’ qualification, and three ‘Metal AM Engineer’ qualifications. Each of the seven qualifications focuses on one of four metal additive manufacturing processes closely aligned with welding: laser-based PBF, electron beam PBF, laser-based DED, and Arc DED.

There are also other qualifications currently in the planning phase. This includes programs intended for designers, supervisors, inspectors, and further technical qualifications for other metal additive manufacturing processes, with future updates soon to be presented by the EWF.

All of the qualifications of the IAMQS were developed under the scope of two European Erasmus+ funded projects – ADMIRE and CLLAIM. Furthermore, each and every program is aligned with the ISO-ASTM standards for additive manufacturing qualifications.

Operators, Coordinators, and Engineers

Those interested in going down the operator route have eight modules available to them, including processes, quality assurance, health & safety, and even post-processing. The laser-based processes also have two additional competence units for powder handling and laser beam characterization. The first set of countries offering the qualifications comprises Italy, Germany, France, Portugal, Spain, and the UK.

Alternatively, those interested in going down the engineer route will have a curriculum comprising five general mandatory topics and an additional three based on specific AM processes. These initial eight modules are also a part of the Metal AM Coordinator profile. In order for the student to obtain a Metal AM Engineer Qualification, they will be required to complete the initial eight modules plus a specialization in one of the three major AM processes. On top of this, a specialization in two AM materials from a previously defined list will also be mandatory.

Further details of the international qualification system can be found in the Whitepaper here.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed metal components. Photo via EWF.