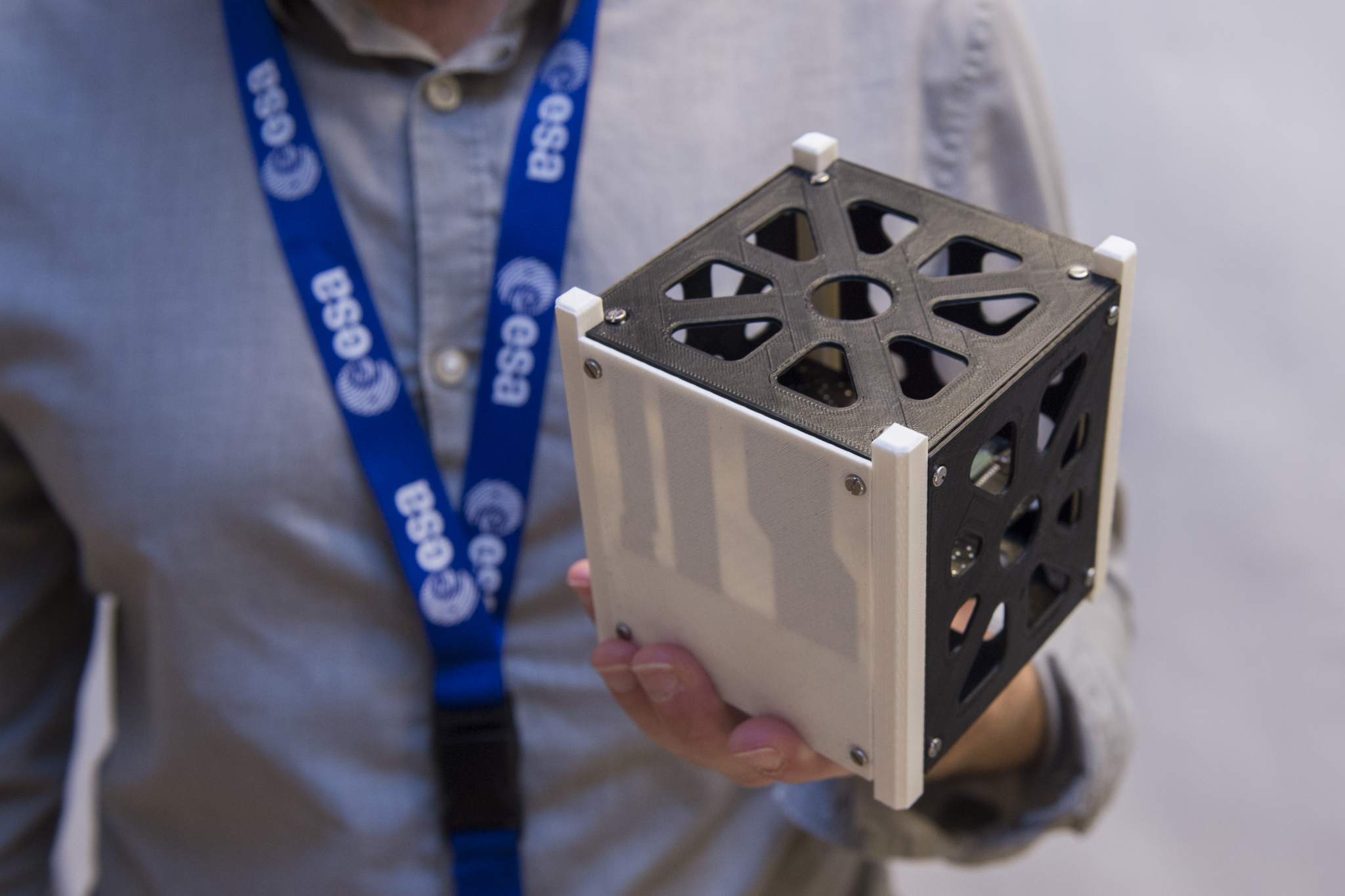

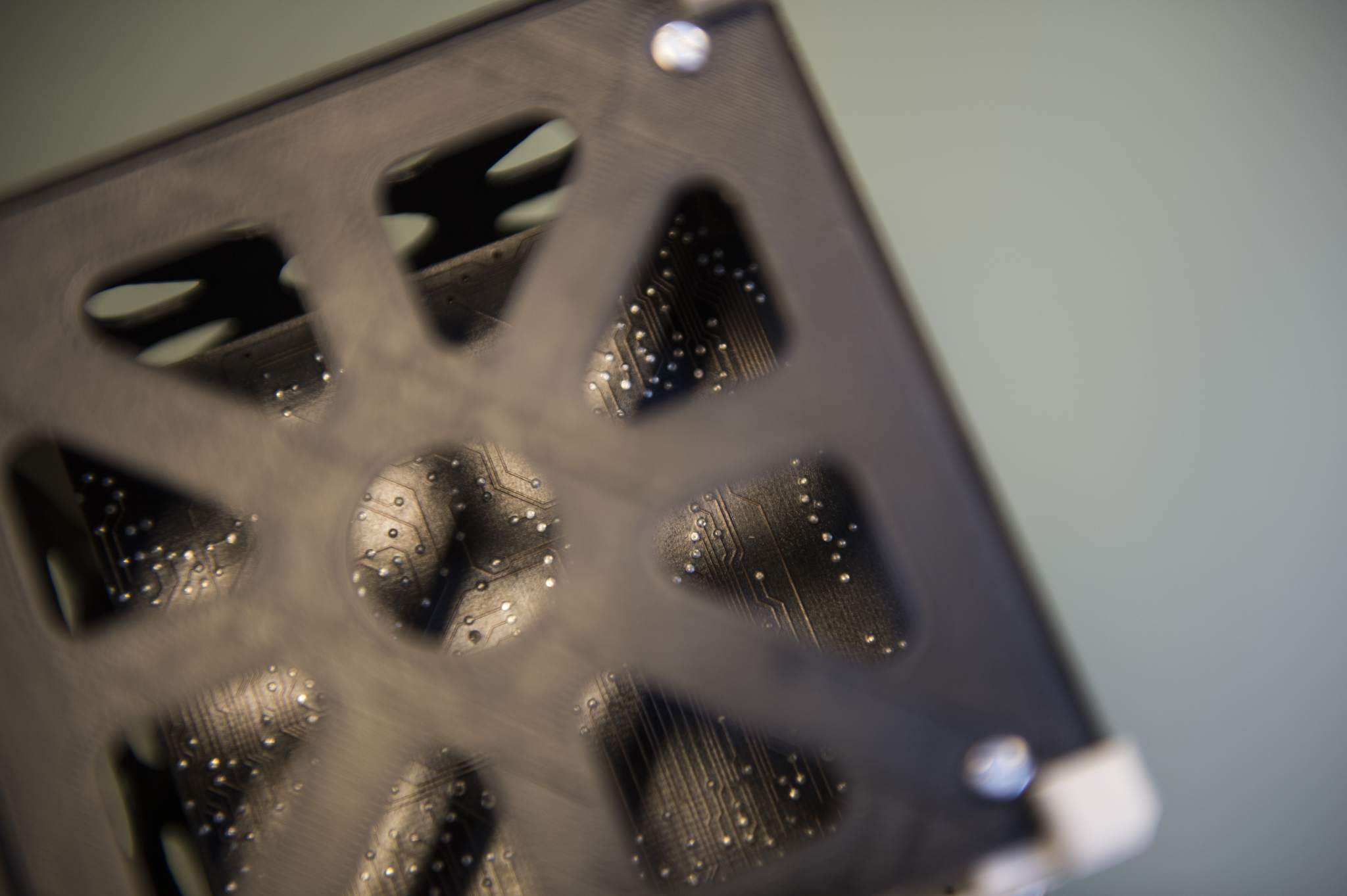

The European Space Agency (ESA) is 3D printing the bodies of CubeSats out of a modified and electrically conductive PEEK plastic.

According to the ESA, the group is currently testing the use of a doped PEEK material having collaborated with Portuguese materials company PIEP. By using the modified PEEK, conductive lines can replace the wire harness that is used to connect CubeSat subsystems.

The European Space Agency has also revealed plans to develop a PEEK 3D printer that can operate in space in a similar way to the Made in Space 3D printer.

PEEK into space

Space Materials & Technology Specialist, Ugo Lafont explains his branch of the ESA is currently focused on “3D printing using ‘polyether ether ketone’ – or PEEK.” This is because the advanced thermoplastic has “very good intrinsic properties in terms of strength, stability and temperature resistance, with a melting point up around 370ºC.” The 3D printed PEEK CubeSat is light, and compared to other satellite fabrication methods, cheap to produce. 3D printing was also used recently by Indian teenager Rifath Sharook, to develop “the world’s lightest satellite.”

Lafont states ESA took the project one step further by developing a conductive material. This saves space and increases the functionality of the devices. He explains,

We started a project with Portuguese company PIEP and, in a technical first, we made this printable PEEK electrically conductive by adding certain nano-fillers to the material.

Ugo Lafont also believes the material “is so robust that it can do comparable jobs to some metal parts.” For similar reasons, Franco-Italian company Thales Alenia Space has also begun implementing thermoplastics in its satellite production. The ESA’s first PEEK 3D printed structure is expected to launch as part of the Meteosat Third Generation weather satellites in the next few years.

PEEK 3D printer in space

Additionally, the ESA has revealed it intends to now develop a machine able to 3D print PEEK materials in space.

The ESA’s Materials’ Physics & Chemistry team will be collaborating with ESA’s Directorate of Human Spaceflight and Robotic Exploration to test a space-optimised PEEK 3D printer on zero-g airplane flights. Following this, the space agency hopes to send a machine to the ISS to join the Made in Space printer to produce “all kinds of items.” As Ugo Lafont explains,

Space Station crews end up needing all kinds of items, all of which currently require transport from Earth: everything from screws and water valves to hermetic containers and water valves. All of these could be 3D-printed instead – even toothbrushes – since PEEK is biocompatible.

In the future, this device could support the Made in Space’s 3D printer and proposed Archinaut system which aims to fabricate large parts in space.

For all the latest space 3D printing news, subscribe to our newsletter, follow us on twitter and like us on Facebook.

Featured image shows an artist’s impression of Cubesats in orbit of the earth. Photo via ESA/Medialab.