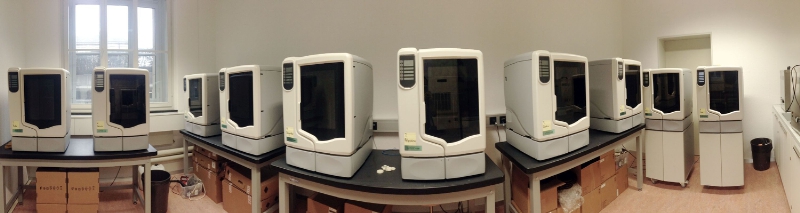

The Swiss Federal Institute of Technology Zürich (ETH Zürich) has recently invested in multiple Stratasys uPrint SE Plus 3D Printers to enrich their undergraduate engineering program. The announcement follows ETH Zurich’s decision to modernize their CAD course and Technical Drawing courses by seeking out the latest technological support. Dr. Kristina Shea, head of the Engineering Design and Computing Laboratory at ETH Zurich says that Stratasys’ uPrint SE Plus 3D was chosen from a number of other similar printers on the market for its reliability in producing high-quality, functional parts. Shea says, “The course has between 450-500 students, so reliability was essential and a big part of our decision to invest in a professional 3D printer. We had previously relied on CAD and modeling on a screen, but using high-quality, functional physical models ensures students are far more engaged.”

ETH Zürich uses ivory ABSplus FDM material for all of their prints. It is an ideal prototyping material and is made of a strong and stable thermoplastic. Stratasys’s uPrint SE Plus prints layer thicknesses of 0.330mm and 0.254mm, which is excellent for students requiring precise parts.

Now that students have the uPrint SE Plus 3D Printers at their disposal, the course guidelines have changed to include an interesting project where students customize and build a balloon-powered car model. This project requires students to utilize their CAD modeling skills, as well as their 3D printing prowess to print out various iterations of car parts. Dr. Shea explains:

Thanks to 3D printing technology, we’ve given students the tools to design and prototype the wheel spokes and the top of the cars. The first time we 3D printed parts, we did it in six days, running overnight. With nine parts to each car, it was a huge job, therefore you can see why the reliability of a professional 3D printer was integral to such a large investment. We now call them our ‘little workhorses! I was particularly interested in the effect of using 3D printed models on students’ motivation. With 3D printing, we saw increased motivation in learning to use the CAD software. The appreciation of scale and the importance of production tolerances grew when the customized parts the students had designed were 3D printed and assembled. Even though design manufacturing guidelines were provided, there were marked increases in understanding as a result of the material realization of their designs.

Stratasys’s General Manager for Global Education, Sig Behrens says “We believe in empowering engineering students with 3D printing skills of the modern workplace and this is a strategy that many leading institutions, like ETH Zürich, are committing to and investing in. The ability to access and familiarize students with professional 3D printing technology is incredibly important, because these are tomorrow’s designers and engineers. With its desire to embrace 3D printing, ETH Zurich is bridging the gap between academia and industry by fulfilling the demand for skills that employers are seeking.”