Leading 3D printer manufacturer EOS has launched a series of periphery devices to help automate and accelerate additive manufacturing in production. Developed through the company’s Next Generation Additive Manufacturing (NextGenAM) initiative, EOS Shared Modules are made to handle equipping, unpacking, transporting and sieving activities parallel to the AM build process.

Currently offered for the EOS M 400 series, and to be extended to the M 300, the Shared Modules allow manufacturers to configure their own production scenarios and select which modules they need. “We are proud to have developed EOS Shared Modules from a visionary concept to a mature solution,” stated Dr. Hannes Gostner, SVP of the Metal Systems Division at EOS.

“The interaction of its various elements has already proven itself in the NextGenAM project; now it is commercially ready.”

The first demonstration of EOS Shared Modules will be made at Formnext 2019 with commercial availability to follow by the second half of 2020.

NextGenAM

The EOS Shared Modules concept was first illustrated as part of the NextGenAM project the company shared with automotive manufacturer Daimler and aerospace company Premium AEROTEC. Completed in April this year, the NextGenAM project effectively verified the Shared Modules configuration in the series production of a replacement bracket for Premium AEROTEC diesel engines. Now closing its doors to publicity, the pilot plant is undergoing a test production run of a series part of Daimler. Commenting at the time of the project’s completion Dr. Thomas Ehm, Chairman of the Executive Board at Premium AEROTEC, stated, “”The aim now is to build further on this expertise and to bring it to bear in other sectors as well. The successful conclusion of NextGenAM thus represents another important building block in our strategy.”

EOS Shared Modules

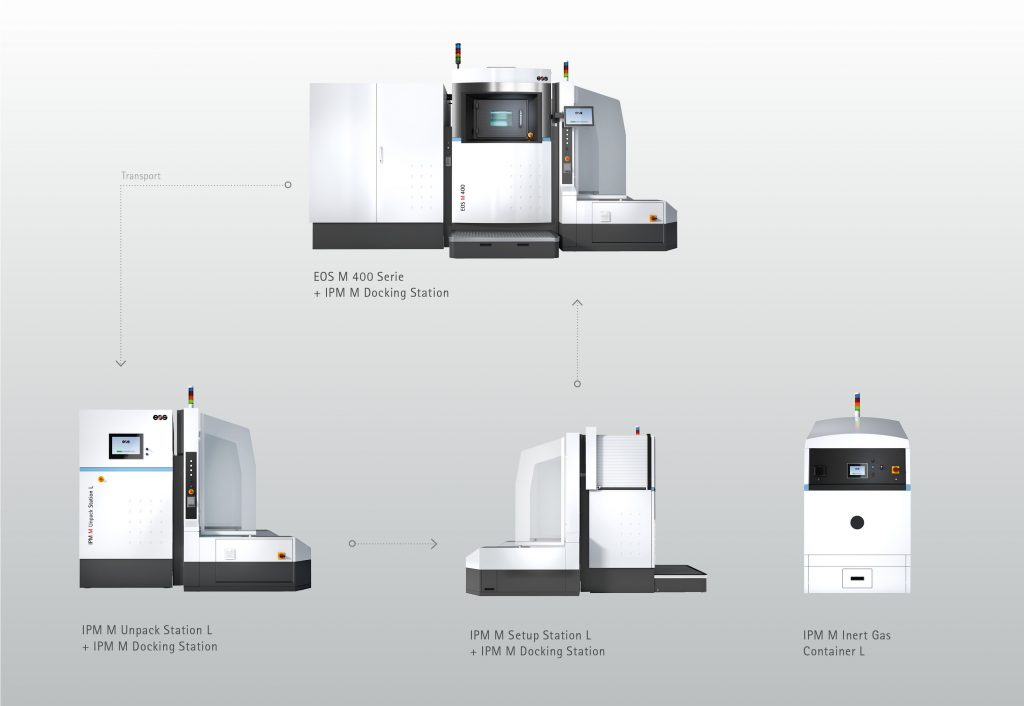

EOS Shared Modules are offered in two configurations: Manual, in which interaction is required for transport between modules, and Automated, which uses a guided vehicle to deliver builds and materials between the various stages of the process. In the manual configuration, the exchangeable frame containing unmelted powder and 3D printed parts, is transferred to a powder-tight IPM M Manual Xframe Container. Transportation of this container, between cooling, post-processing and powder retrieval by a standard pallet truck. An IPCM-M extra or IPCM-M pro system for sieving and preparation of powder post-build is also offered separately in this configuration for recycling and reusing powder.

In the automated EOS Shared Modules configuration, the exchangeable frame is automatically moved from the 3D printed into a gas-tight IPM M Inert Gas Container L. Fully automated, this container is then moved to the next station using a guided vehicle, however a standard pallet truck can also be used in its place. An IPM M Powder Station L solution is available separately for the IPM M Inert Gas Container to remove and recycle used powder.

Most of the modules in this series are completed by a docking station to facilitate frame access. An IPM M Unpack Station L and IPM M Setup Station are also available as part of this solution, helping in the preparation of build.

Modularity is a clear advantage for customers applying this solutions, in addition, it makes it easy to scale up production. Dr. Gostner explains, “As demand grows, customers can increase the number of EOS M 400 or EOS M 400-4 systems and expand EOS Shared Modules accordingly if necessary.”

EOS will be exhibiting its latest advances at Formnext from 19 – 22 November 2019 in hall 11.1, booth D31.

For 3D Printing Industry’s live coverage of this event and more subscribe to our newsletter for the latest additive manufacturing business news. You can also stay connected by following us on Twitter and liking us on Facebook. Looking for a career in the industry? Visit 3D Printing Jobs for a selection of current roles.

Featured image shows a visual of an EOS metal additive manufacturing factory. Image via EOS