Berlin-based software company 1000 Kelvin and EOS have announced the integration of the AMAIZE platform into the EOS software suite.

This integration aims to optimize production workflows and improve engineering processes across industries such as aerospace, energy, and contract manufacturing. By leveraging AI technology, clients can expect to streamline their design processes, potentially leading to a reduction in engineering costs of up to 80%.

Omar Fergani, CEO of 1000 Kelvin, said, “The integration with EOS software is a testament to the open architecture of EOS products and the extensive resources of the EOS Developer Network (EDN). These factors have allowed us to seamlessly incorporate the EOSPRINT APIs into our platform, ensuring that our customers can effortlessly benefit from the combined strengths of our technologies.”

AI-powered precision manufacturing via AMAIZE

This integration’s early adopter FKM, a European AM contract manufacturer, suggested positive outcomes having experienced improvements in engineering speed and product quality. Matthias Henkel, CEO of FKM, added, “1000Kelvin’s AMAIZE aligns perfectly with our commitment to digital excellence in manufacturing. It allows our engineers to predictively navigate complex components quality and consistency requirements.”

Martin Steuer, Senior Vice President of EOS’s Software Division, emphasizes the importance of AMAIZE’s AI predictive capabilities in facilitating a shift from physical to digital iteration and advancing the industrialization of additive manufacturing. The integration also introduces enhanced cybersecurity features, offering clients access to cloud-based solutions within EOS’s open ecosystem platform.

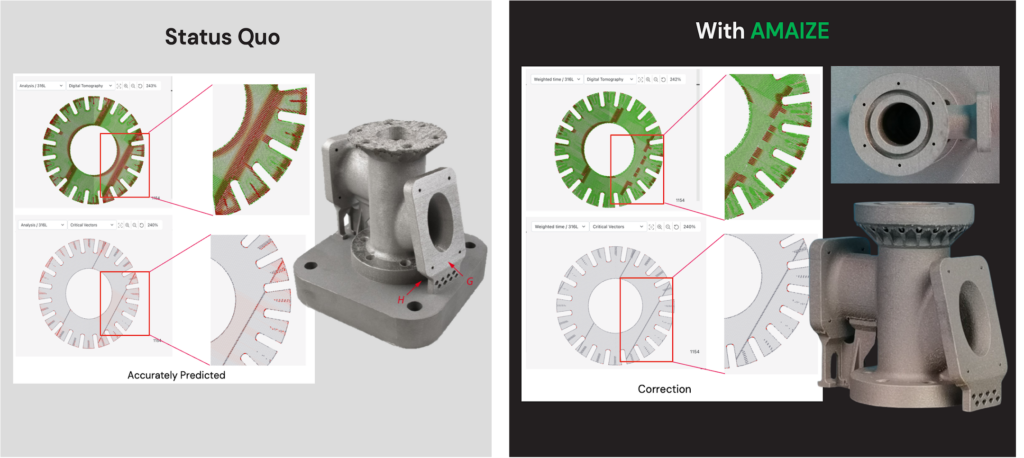

Debuted at Formnext 2023, 1000 Kelvin’s AMAIZE platform analyzes part files and adjusts parameters. It also optimizes 3D print recipes, reducing the need for costly iterations and simulations. Integrated with major machine OEMs, the cloud-native solution finds success in the energy, aerospace, and contract manufacturing sectors.

One of the case studies provided by the company included a rocket launch provider in California who overcame print failures with AMAIZE, achieving better quality and cost savings. Notably, AMAIZE enabled an 80% reduction in support structures, slashing overall costs by over 30% and accelerating time to market.

In another news, 1000 Kelvin and Fieldmade announced the integration of AMAIZE with Fieldmade’s NOMAD series to deploy 3D printers in combat zones, enhancing military readiness. This move enables users in combat zones to quickly adapt to operational manufacturing needs by optimizing the printing process as soon as the module arrives on site.

AMAIZE aligns seamlessly with Fieldmade’s deployable additive manufacturing technology, offering its AI capabilities to enhance the efficiency and effectiveness of on-site 3D printing operations. By leveraging AMAIZE, military personnel can achieve rapid, high-quality part production directly in combat environments, contributing to increased readiness and operational capabilities.

Latest AM software optimizing manufacturing processes

In addition to 1000 Kelvin and EOS, numerous other 3D printing companies have introduced notable software innovations in recent months. This month, 3D printing materials producer polySpectra introduced neThing.xyz. It democratizes 3D CAD model creation by harnessing AI-driven generative design, making it accessible to a wider audience. Available at no cost, it facilitates digital-to-physical translation, offering AI-generated 3D models and AR previews.

This software offers easy customization of designs and seamless collaboration among users. The platform supports multiple file formats and enables direct 3D printing initiation. With a focus on simplicity, neThing.xyz provides engineers, designers, and enthusiasts a tool to explore new dimensions in digital creation.

Elsewhere, AM software company Tech Soft 3D launched HOOPS Luminate, a graphics software development kit (SDK) specializing in advanced real-time rendering. This solution offers a range of features including rendering control, image quality tools, and access to a materials library.

It also supports various rendering types, rasterization, and ray-tracing technologies, allowing developers to seamlessly share data for both real-time and ray-tracing renderings through a single C++ API. Compatible with Windows, macOS, and Linux, it integrates with HOOPS Visualize to enhance engineering graphics. HOOPS Luminate is a key component of the HOOPS SDK suite, meeting the demand for high-quality rendering in engineering software applications.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 1000 Kelvin’s software acts as an autocorrect copilot for 3D printing. By using a physics-informed AI, AMAIZE automatically identifies and corrects issues in a print file without altering the original design to achieve a perfect part the first time it is printed. Photo via 1000 Kelvin.