Researchers based at the Indian Kongu Engineering College have 3D printed a miniature bluetooth-controlled UAV that could be capable of evading capture within covert military operations.

Measuring less than 100 x 100 mm, the engineers’ tiny X-shaped quadcopter can be built using low-cost components, enabling it to be reproduced cheaply on an industrial scale. According to the team, their PLA-based drone holds the potential to “fly between enemy lines” and conduct intelligence-gathering recon missions, eliminating the need for satellite monitoring and international espionage.

Drone design innovation

Since the term ‘UAV’ was first used in 1946, the size and capabilities of autonomous drones have changed dramatically, and they’re now often deployed within traffic control, rescue and weather monitoring applications. Using low-cost sensors and everyday bluetooth devices, it’s also easier than ever to build UAVs that are capable of carrying out either remote-controlled or pre-programmed flight paths.

In terms of raw power, many such quadcopters have sufficient computational grunt to perform calculations during data acquisition, and meet the needs of everyday civilian tasks. However, when it comes to more demanding aerospace and military applications, it remains difficult to incorporate the processing power and error detection software required to conduct detailed recon, within compact casings.

By contrast, the ever-increasing accessibility of 3D printing continues to unlock new applications for the technology, and the Indian engineers have now found it possible to use a conventional Ultimaker FDM 3D printer, as a means of creating a remote-controlled drone that’s capable of surveillance, flight stabilization and landing on any terrain.

Building an evasive quadcopter

Based around a single-piece 3D printed body, the team’s UAV features attachable wings for improved stability, as well as 65 mm x 65 mm flight controllers, that are easily small enough to fit into its tiny frame. The copter’s other major motor, circuitry and battery components are all similarly compact, but consist mainly of parts that can be easily acquired online, ensuring its future accessibility.

Once the team had constructed their prototype, they found that its cheap DC motors were capable of providing lift when the device’s propellers were turned in opposite directions. After some test driving, the drone proved able to move in six directions via a bluetooth-connected smartphone, and the engineers observed that it was an “easier task” than it would’ve been using a transmitter and receiver.

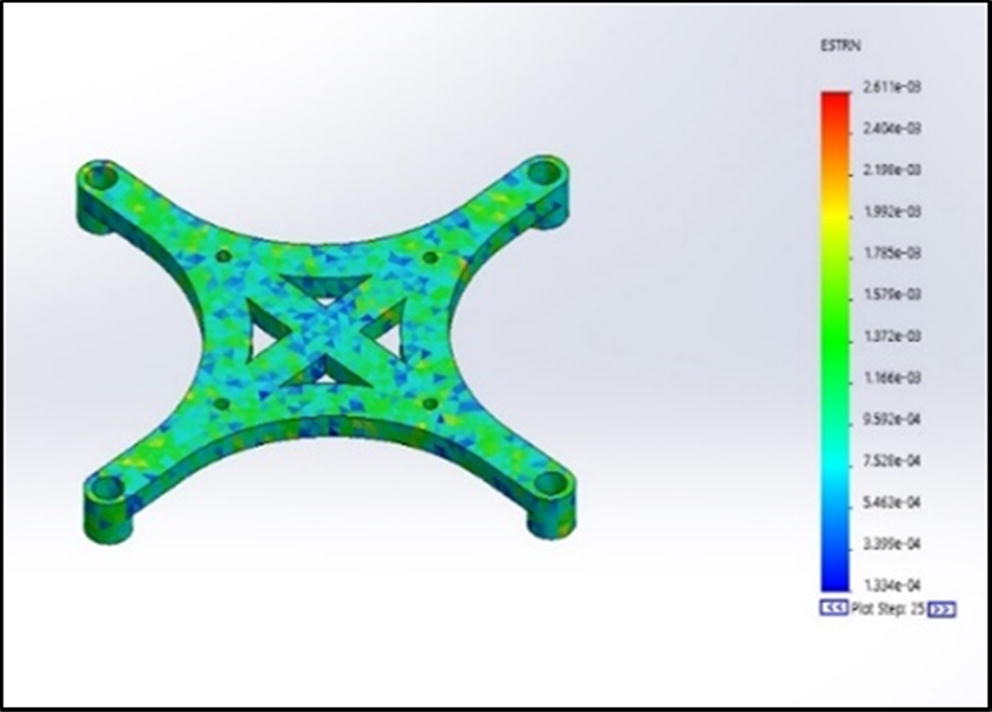

Rather than crash their prized asset during testing, the team later opted to simulate a crash landing using SOLIDWORKS, finding that its fragile frame could only survive under stresses of up to 10 MPa. Additionally, in lengthier runs, the drone was barely capable of flying continuously for ten straight minutes, placing a clear limitation on its potential efficacy within long-distance military surveillance applications.

Despite this, the engineers maintained that their device was able to perform image capturing in both GPS-enabled and non-satellite modes, lending it precise navigational and map-building capabilities. What’s more, the team also identified that they could either retrieve data via a conventional SD card or advanced AI devices, giving the drone potential VR functionality.

As a result, the researchers concluded that their mini-UAV has the shape, size and affordability needed to put “spies and surveillance satellites” out of business in future, but it may also need a slightly longer battery, unless state recon recedes in scale to the point that spying on close neighbors becomes of national importance.

3D printing UAVs at scale

Although the idea of 3D printing UAVs is far from novel, many existing drones have deliberately been built on a grander scale, with durability and demanding military applications in mind. Australian metal 3D printer manufacturer Titomic, for instance, has used its Titomic Kinetic Fusion (TKF) technology to create what it claims to be the ‘world’s largest UAV.’

With a total diameter of 1.8 meters, the lightweight-yet-durable drone is constructed of fused dissimilar metals, potentially enabling it to provide military-grade performance. Similarly, South African start-up Aeroswift has previously 3D printed a titanium UAV that’s over 1.5 meters in height, albeit only as a demonstration of its technology’s capabilities.

On a smaller scale, students at the University of Warwick have developed a 3D printed mountain rescue UAV, that’s designed to help carry vital supplies to those in need during missions. Built as part of the UK government’s Horizon (AM) program, the drone proved capable of carrying up to 5 kilograms for over 80 kilometers.

The researchers’ findings are detailed in their paper titled “Structural analysis of mini drone developed using 3D printing technique.” The research was co-authored by N. Muralidharan, V.G. Pratheep, A. Shanmugam, A. Hariram, P. Dinesh and B. Visnub.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D model of the Indian team’s 3D printed drone frame. Image via the Materials Today: Proceedings journal.