Hardcotton, based in Cantberra, Australia, has announced the release of a new 3D printer that the company claims to be “like no other”. Hardcotton’s Elemental is a stereolithography (SLA) 3D printer, using a laser to cure photosensitive resins, but it distinguishes itself from other SLA machines in that uses a pressure control system to manage the levels of resin in which an object is printed. This patent pending pressure system moves the resin to and from the build area, which reduces the amount of set up and calibration necessary before printing can begin.

Most SLA machines suspend an object upside down, into a vat of resin. As a laser cures a layer of resin, the object is slowly pulled upwards and the next layer is cured. With the Elemental, however, is seems that only the required amount of resin is, instead, injected into the build area with each layer. This both removes the need for the extensive number of support structures, seen with other SLA machines, and the mechanical parts needed to lift the print out of the vat.

In addition to the innovative pressure system design, Hardcotton has also come up with a method for utilizing non-curable material, such as saline, to act as the support for a print. That way, only the curable resin is hardened by the laser, leaving the saline to be easily washed away. Pobihun adds, “Elemental makes 3D printing simple, easy and affordable. Unlike other printers on the market, Elemental does not require complex set-up, assembly or calibration. Its modular design addresses cost concerns, usually a concern with SLA printers, as well as ensuring performance reliability with whisper quiet operation.”

The CEO further suggests that this design could be incorporated into other 3D printing technology soon, as manufacturers catch wind of their unique pressure control system, “It really is amazing seeing something 3D printed. It is even more amazing when the print is done quickly, quietly and simply. Utilising pressure control, Hardcotton has developed a 3D printer that employs SLA technology but creates the 3D print without the use of a mechanical platform. This is a massive step forward for 3D printing. Because there are very few complex parts to be assembled in Elemental, we see this architecture as being the basis for the mass manufacture of 3D printers very soon.”

The company lists the Elemental’s specs as follows:

• Custom hardware, firmware and client software that accepts industry standard g-code

• Very large build area for SLA:

> 200mm x 200mm x 200mm (7.87in x 7.87in x 7.87in) with single control chamber configuration

> 140mm x 140mm x 200mm (5.51in x 5.51in x 7.87in) with dual control chamber configuration

• Z control accurate to 1 micron (depending on resin used and limited to 1 micron by microcontroller settings)

• XY control resolution up to 24.4 micron (variable through software)

• Variable output 405nm laser

• Pressure control of layer height

• Bluetooth functionality

The Elemental will be launched on Kickstarter in the third quarter of this year, with Kickstarter backers able to purchase it for under AUD$1000 (about $948 USD ). Personally, I can’t wait to see more of this unique printer, including videos of the machine in action. For such a low price, the Elemental could undercut its competitors significantly.

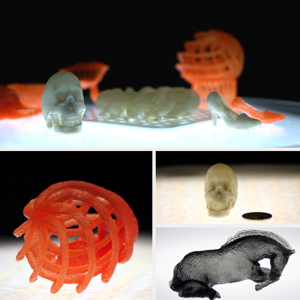

Credits (via Hardcotton): Hardcotton has not created designs for any of the objects printed out using Elemental. Designs have been downloaded free of charge from Thingiverse & GrabCAD.