British 3D printing technology developer and marketplace E3D-Online has announced the topic of its current research: a tool-changing 3D printer platform.

Developed in-house as a project that E3D believes “might be the coolest thing to hit 3D printing in a very long time,” the company is seeking input from the Maker Community to give production the go-ahead.

As stated in the official blog post for the research, “A tool-changing system done properly is a BIG DEAL.” It “opens huge future opportunities,” and is “a fundamental shift in capability and lays the foundation for future advances.”

Multimaterial 3D printing made easy

The Beta-stage prototype of this platform works exclusively with FFF extrusion technology. The team intend to add further toolheads based on customer demand. “We want to be ready for the future,” states the blog, “to open the door for the easy addition of tools that are not just additive.”

Hybrid additive/subtractive manufacturing is one possible route. As is metrology heads, probes, lasers, pick-and-place, vision sensors and inkjet printheads.

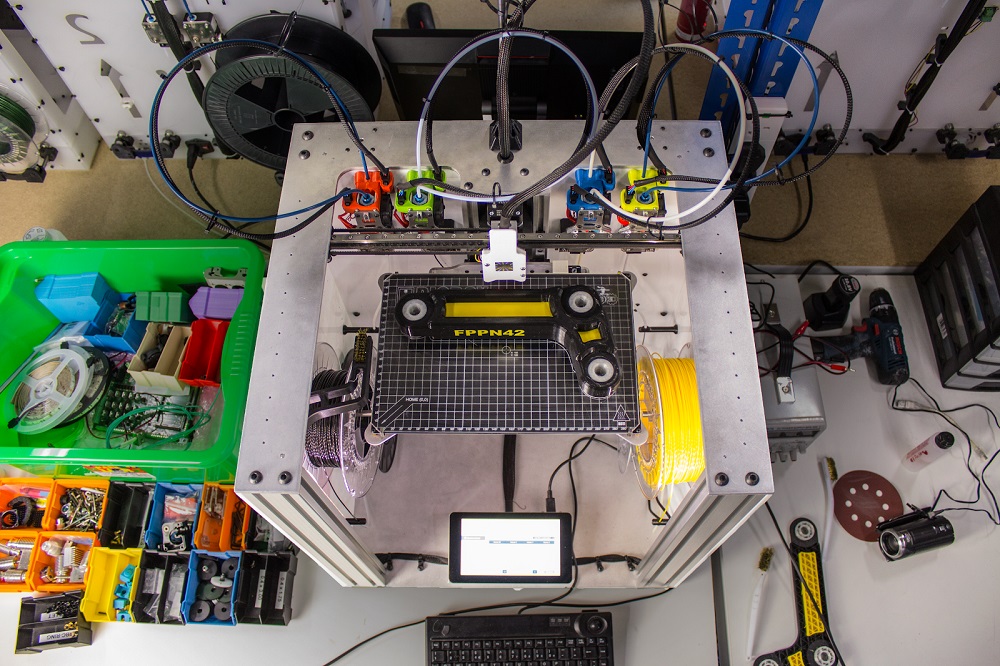

At present, the system functions as a multimaterial 3D printer. Capable of working with up to four different printheads (and more) the system overcomes many of the challenges associates with “Normal” multimaterial 3D printing, namely nozzle oozing, filament purging, and slower print speeds due to a heavier (i.e. dual nozzle) head.

Intelligent mechanics

Development of the tool-changing 3D printer so far consists of two parts – a tool-changer, and a motion-system – that enable the seamless and speedy exchange of toolheads.

The tool-changer is made possible by the kinematic coupling of fixtures and the select part; a lightweight electronic grabber; a Sprung Bayonet cam-lock that slots into each toolhead; permanent magnets to fix the tools to the dock.

To support the tool-changer, E3D heavily invested in a motion-system capable of picking tools with sub-5μm accuracy.

How to get involved

Last month E3D released a new range of dual extrusion printheads, suitable for use in its previous R&D project to make a water cooling 3D printer system.

For £120 ($169 USD) 3D printing veterans interested in the system can register for a guaranteed place on the waitlist for a tool-changer platform. E3D is also searching for partners to contribute to the project.

The price for a finished tool-changing system has been estimated by E3D between £1,000 and £2,000 (Approx. $1,408 – $2,817 USD).

For more research, hardware and materials releases subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking to get involved in a new additive manufacturing project? Join 3D printing jobs for the latest vacancies from many key players in the industry.

Vote now in the 2018 3D Printing Industry Awards for technologies and research projects of the year. Want to design the trophy? Enter the 2018 3D Printing Industry Awards design competition. sponsored by Protolabs now.

Featured image shows The E3D tool-changing platform. Clip via E3D-Online