Dyndrite Corporation, a Seattle-based software company, has introduced the Additive Manufacturing Toolkit (AMT) and accelerated production preparation build processor for 3D printing.

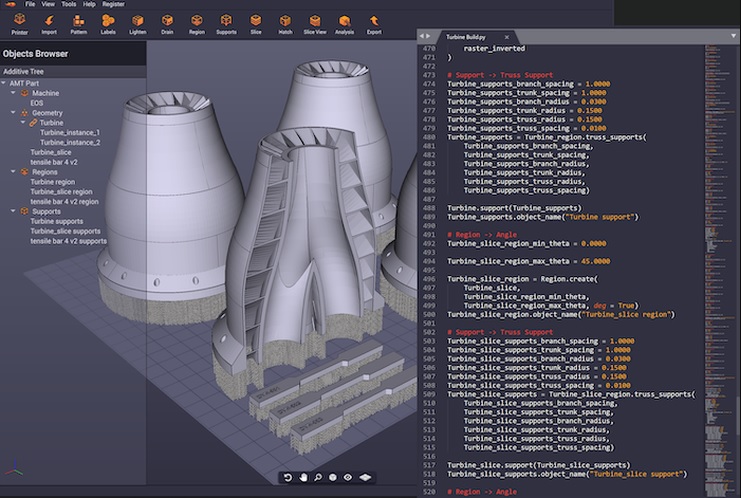

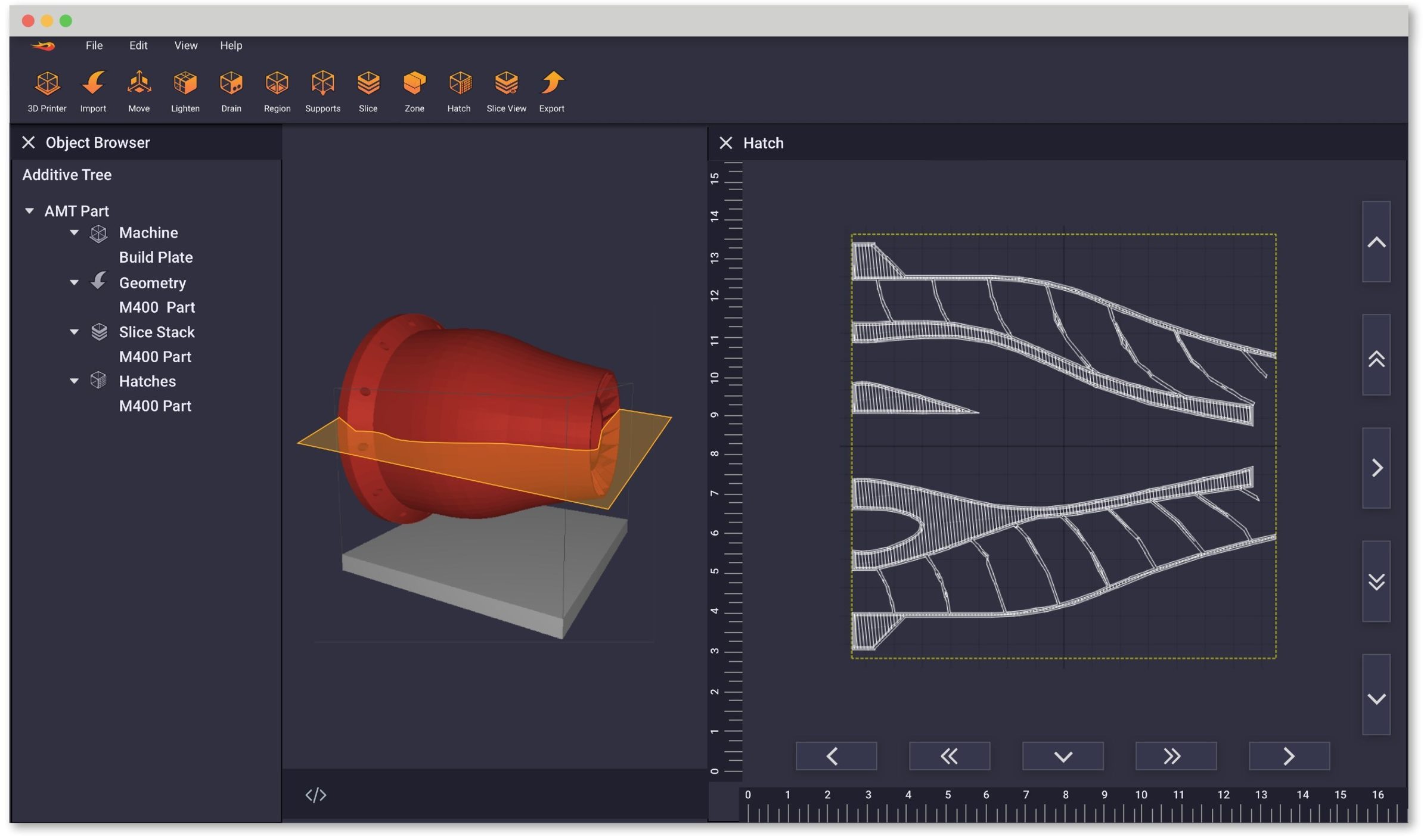

AMT is based on the company’s Accelerated Computation Engine (ACE), a GPU-powered geometry kernel, and is capable of importing native CAD files for maximum quality of 3D printed output. It also features an integrated Python application programming interface (API) for customizable scripting of interactive, automated workflows.

“The Dyndrite Accelerated Computation Engine is a genuine paradigm shift and promises to do for 3D printing what Adobe and PostScript did for 2D printing in the 1980s,” said Harshil Goel, founder and CEO of Dyndrite.

“We intend to set off a similar revolution – 3D printers powered by the Dyndrite ACE will totally reshape the productivity of design and manufacturing as we have known them. The ambitions of additive users such as those in aerospace deserve more than ‘business as usual’ and we have delivered that for partners and customers through the best possible tech.”

Dyndrite’s Additive Manufacturing Toolkit

The Dyndrite Additive Toolkit enables a streamlined CAD-to-Print workflow for industrial additive manufacturing. Users can manage terabytes of manufacturing data, print higher-order geometries and adjust parts in-situ to increase both throughput and quality. The AMT build processor is said to leverage modern methodologies to meet the requirements of production-oriented customers in the aerospace, medical, automotive, energy and service bureau markets.

Presently, the software is capable of handling datasets beyond 225M STLs (>10GB verified,); accelerating lattice and support generation, reducing hours of processing to minutes; labeling parts while retaining original geometry; streamlining User Interface (UI) & User Experience (UX) greatly simplifying build prep process.

Furthermore, its Python interface creates a script for workflows. The feature “Save as Python”, allows non-technical users to work in the Graphical User Interface (GUI) to easily produce Python code that can be “rerun” by all.

Dyndrite Developer Program and Council

The company has also announced the inclusion of simulation and topology optimization pioneers Ansys, Altair, as well as 3D Systems, SLM Solutions, and ExOne into the Dyndrite Developer Program and Council. Furthermore, it has partnered with Renishaw to integrate the Dyndrite AMT into the company’s QuantAM build processor.

“The future of Additive Manufacturing is all about speed – of design iteration, simulation, build preparation and printing to deliver creativity, flexibility, increased part volumes and economical parts,” added Stephen Anderson, Additive Manufacturing Business Manager at Renishaw.

“We need to measure as we build and be able to analyze the enormous accompanying data to adapt the next build or even the next layer. Processing that data quickly requires massive computational power – GPU cores and lots of them!”

Formnext visitors can see the latest innovations from Dyndrite at Hall 12.1 Booth G131.

For all of the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the Dyndrite Additive Manufacturing Toolkit with Python interface. Image via Dyndrite.