Dassault Systèmes, the French software company behind the 3DEXPERIENCE platform, has partnered with the University of Sheffield Advanced Manufacturing Research Centre (AMRC) to accelerate manufacturing in the UK.

“We strongly believe that we have entered the Industry Renaissance, a new era where experience will be at the heart of everything we do, from the way we innovate to the way we produce goods,” said Séverine Trouillet, Global Affairs Director, EuroNorth at Dassault Systèmes.

“The tools of the Fourth Industrial Revolution, whether automation, robotics or visualization, are the basis on which we are building a radically new world where entire sectors will be turned upside down.”

“No industry will be transformed quite as much as manufacturing, which is why we are proud to be joining the AMRC and helping its members adopt a digital-first way of thinking, but also create the Future of Manufacturing at the heart of the industrial North.”

Accelerating advanced technologies in the UK

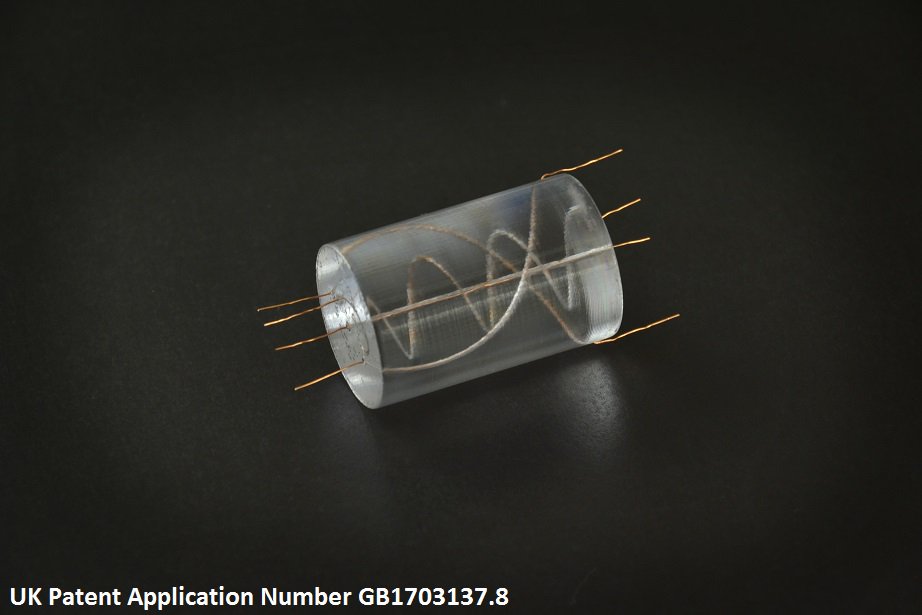

The AMRC, established in 2001, is home to various research projects exploring advanced machining, manufacturing, and materials with over 100 partners. Earlier this year, the center along with engineers at the NASA Jet Propulsion Laboratory (JPL) commenced the development of a hybrid 3D printing technology known as THREAD. This process is capable of adding fibrous electrical, optical and structural elements to the inside of polymer components.

Members of Toyota Motorsport GmbH (TMG), the German-based entity of the automobile manufacturer Toyota Motor Corporation, have also partnered with forces at the AMRC to develop new lightweight automotive materials.

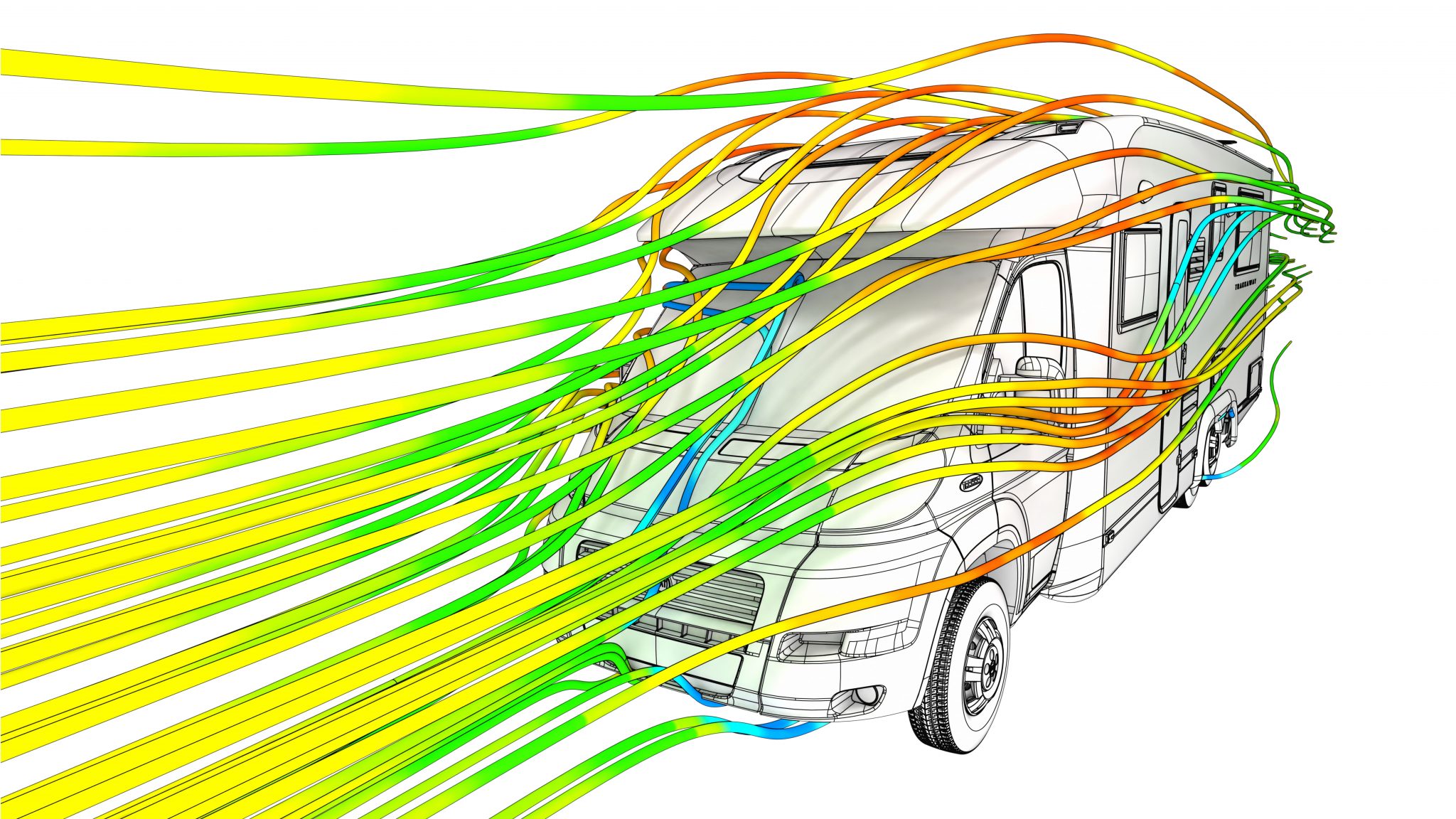

As one of the latest partners, Dassault Systèmes is set to work with UK manufacturers towards the recently launched Made Smarter initiative. This initiative aims to create an open-access Smart Factory testbed for companies seeking to improve productivity, reduce defects and time to market. Thus, Dassault Systèmes’ virtualization and modeling technologies will be leveraged to innovate faster collaboration.

Strengthening the Fourth Industrial Revolution

Rab Scott, Head of Digital at the AMRC added, “British manufacturing has a track record of being among the most innovative and inventive in the world; it was the home of the First Industrial Revolution and it aspires to be the home of the Fourth Industrial Revolution.”

“With Dassault Systèmes as a Tier 1 partner, the AMRC is ideally placed to deliver the sustainable step-changes in productivity that the UK economy desperately needs. Its suite of digital technologies strengthens the AMRC’s portfolio of advanced manufacturing capabilities and puts us at the forefront of Industry 4.0 research and development.”

For more of the latest news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows the University of Sheffield Advanced Manufacturing Research Centre with Boeing. Photo via AMRC.