For a company that has 35,000 employees and is entirely dedicated to printing technologies, Dai Nippon Printing (DNP) has not been overly outspoken about its interest in 3D printing, making no clear mention of it on its website. Nevertheless, the company has been quite active trying to figure out more effective and more affordable applications for 3D printing technologies, especially from a software standpoint.

In the past, it developed a rapid way to 3D print logos from images and studied a system to prevent 3D printing of “dangerous” and forbidden STL files. Its latest venture, in collaboration with the University of Tsukuba in Japan, is the development of a new method for creating detailed models of human organs in photopolymer resin for a third of the current cost.

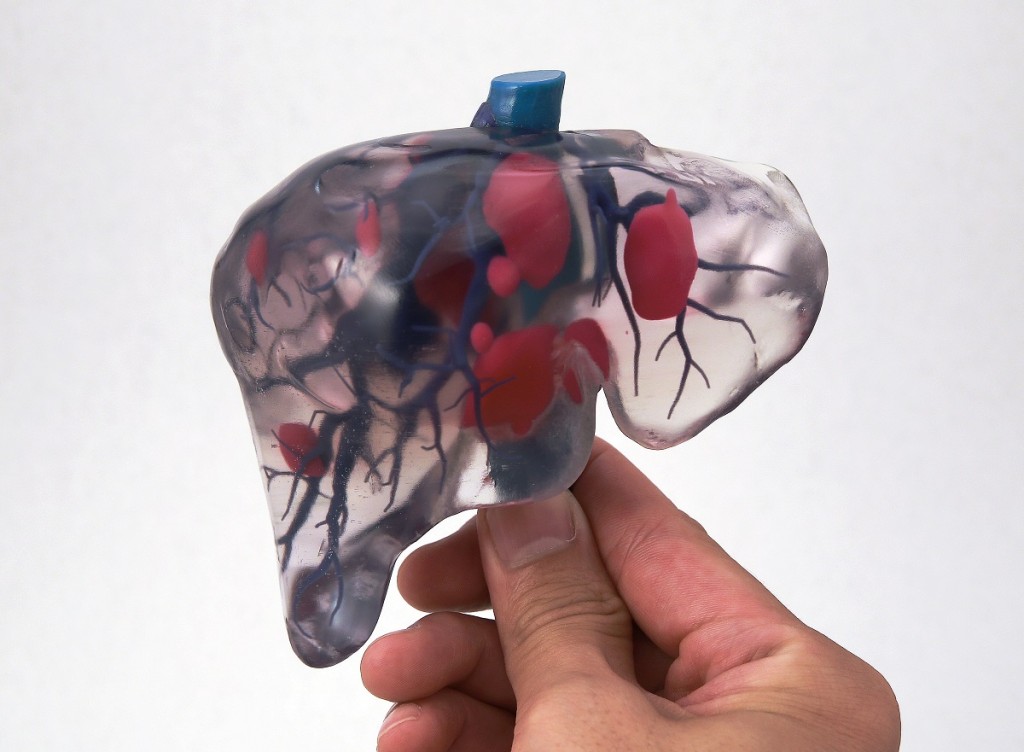

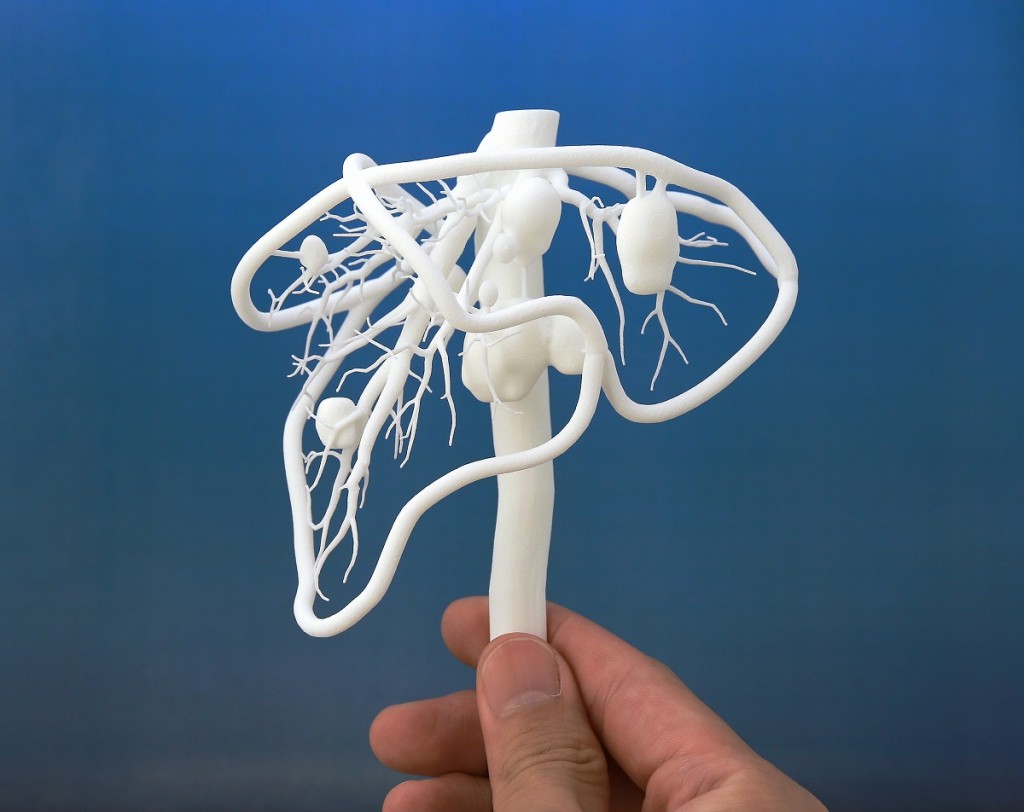

The entire project revolves around the possibility of capturing the 3D data in a way that allows for 3D printing only of the necessary parts of the organs to be operated on. “For example, a doctor can print out a tumor inside the pancreas and blood veins surrounding it, without recreating the entire organ,” a spokeswoman at Dai Nippon Printing said, as reported by the Wall Street Journal.

Most of the cost cutting is, thus, related to the much lower amount of material necessary, as well as the fact that such an approach, in most cases, would not require the use of expensive and complex, highly transparent resins nor that of a multi-material 3D printer. The study also focuses on the fact that even transparent resins carry a certain amount of refraction and that having direct access to the internal parts that need to be operated on can simplify both the pre-surgical operation and doctor-patient communication.

It would seem logical – although there is no direct reference to this in the report – that such an approach could implement single material SLS technology, as well, with a drastic reduction in the cost of materials (albeit, an increment in the cost of the machine).

This particular method for digital fabrication of medical models is now patent pending and is being presented at the 70th Meeting of the Japanese Gastroenterological Association taking place on July 15th through the 17th. The final chapter in the book of medical 3D printing is far from being written. Now, the more direct involvement of huge companies such as DNP shows that there is still a lot more to come.