The idea of 3D printing in construction truly germinated with Enrico Dini’s D-Shape. The large-scale 3D printer, first patented in 2006, caught the imagination of architects and builders worldwide when it built the largest 3D printed sculpture in 2009, Radiolaria, designed by Andrea Morgante. The D-Shape as a new-age building tool, points towards the future of construction, shifting away from the building culture of steel and portland cement, and shrinking the gap between computer design technology and manufacturing. It brings automation and design freedom in construction – whereas traditional construction is largely dependent on skilled personnel, manual labor, molds, and is also an expensive and time-consuming process. In comparison, the D-Shape method is four times faster and its structure realization costs are 30 – 50 % lower.

It’s a work in progress though but its potential is promising enough for the European Space Agency to test it to build lunar bases, and for the military to use it to build bridges, bunkers, and other infrastructure. The D-Shape essentially uses an inorganic binder to solidify 5 – 10 mm sections of any type of sand, dust or gravel. Any structure of almost unlimited complexity can be built within a 6 x 6 x 6 m volume, using a printer head holding 300 servo-driven nozzles, held up by a framework of four aluminium columns.

The concept of using 3D printing for construction has been demonstrated before with the Canal House in the Netherlands, in China with mansions and tower blocks, and elsewhere with houses and castles. It has even been used to build underwater reefs using sand from the seabed. But these have been experiments at best, tiny ripples in the sea of the construction industry. It’s still to be seen how and where this ambitious but fledgling technology will fit in.

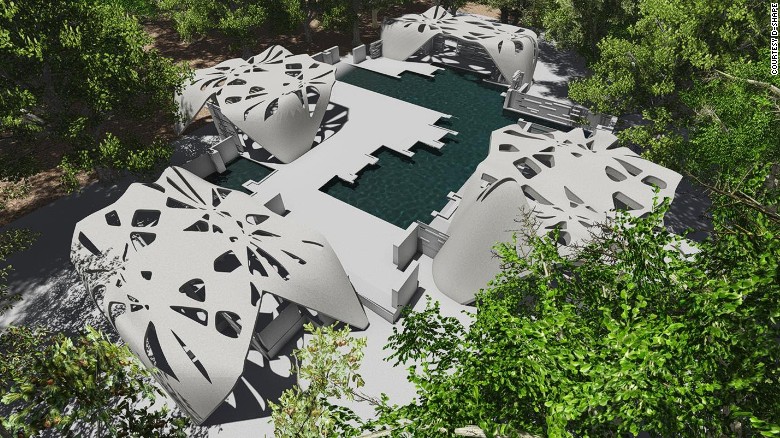

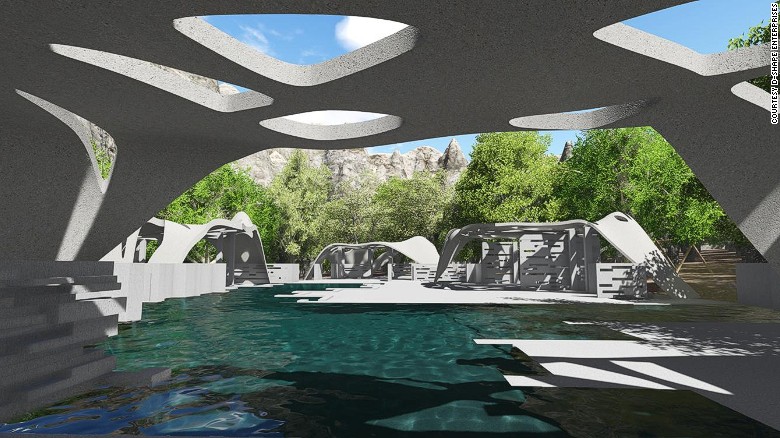

But ambitious it is and last August, architect Adam Kushner received the go-ahead to 3D print an entire estate in upstate New York using the D-shape. For its most challenging project yet, the D-Shape will build a swimming pool, a jacuzzi, a car port, and a 2,400 square foot house on a five-acre plot.

It will use materials found on-site and bind them using a magnesium-based structural ink to build the structures. It isn’t just another experiment. As Kushner says,

“This is not superfluous, nor a lazy architects idyll. I think it’s as important as the automobile was in changing the design of cities or how the printing press altered communication. Why? Because it democratizes construction and architecture and puts it into everyone’s hands, just like the camera phone made everyone a photographer. Not everyone is good at it but everyone can become one.”

Almost a year later, the project is finally underway, with surveying and excavation work about to commence. Difficulty in obtaining clearances from the military for the D-Shape (of which there is only one which is being used in Italy on a project partially funded by Italian Defense Agencies) has prevented the immediate import of the 3D printer into the USA. Now finally moving forward, the pool and jacuzzi should be ready by December this year, while the house could take until 2017.

If the D-Shape successfully proves its capabilities, Kushner feels it would open up a plethora of possibilities in construction and architecture, and not just for commercial purposes, but more important humanitarian ones.

“This will serve as a way of using our project to … pave the way for more humanitarian purposes that we see as the highest and best use for our technology. If we can build a simple pool house, I can print thousands of refugee housings. If I can build a pool, I can print underwater reefs to repair bridges, piers and infrastructures.”

The advantages technologies such as the D-Shape bring tickle the imagination. Just like any other 3D printer, it directly builds from CAD models converted into .stl files. It is fully automated and the machine can be assembled at any location. Its special binder or ‘ink’ is environmentally friendly and allows for the use of existing materials found on-site to build structures that do not require iron reinforcement, have superior traction and resistance than portland cement, and can take almost any form, no matter how complex. Its advanced enough to resemble magic and what’s better, it’s here to stay.

Source & Image Credit: CNN