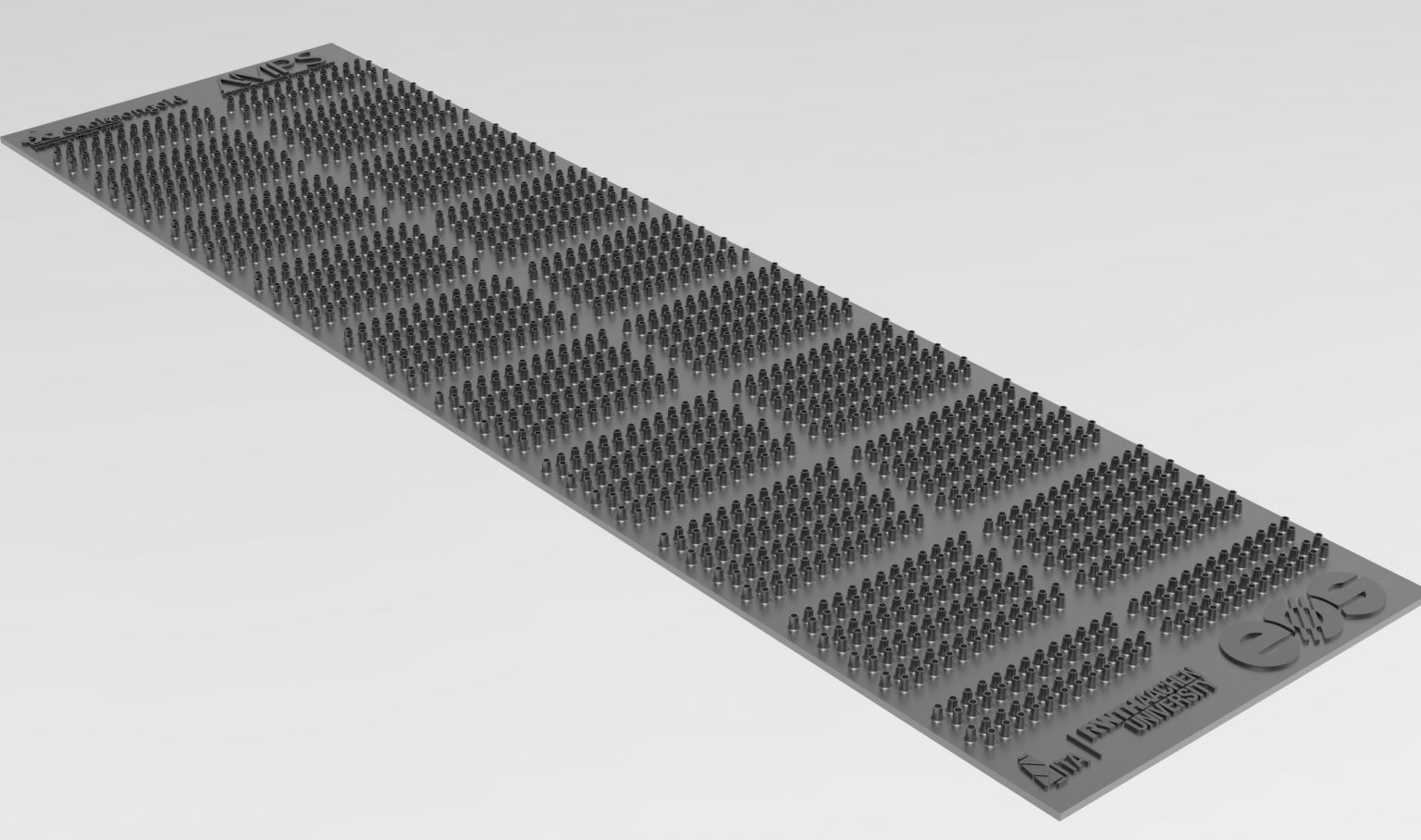

Precious metal specialists Cooksongold AM and Sempsa JP – both part of the Heimerle + Meule Group – have successfully 3D printed the tip plates of a bushing (which is used to extrude glass fibers) using precious metals. The work is intended to develop and innovate glass fiber production in the future and was done in collaboration with the RWTH Aachen Institute of Textile Technology (ITA) and EOS. The platinum/rhodium alloy tip plate has since passed its initial production trials at Johns Manville, a building materials manufacturer, in Slovakia.

Thomas Weitlaner, Director of Additive Minds & Business Development of EOS, stated: “At EOS we are working every day to make industrial 3D printing a sustainable, mainstream manufacturing process. The 3D printing of tip plates is another great example, how additive manufacturing can bring real business value and innovation to the glass fibre industry. Additionally we see a lot more promising applications that can further increase the efficiency of the glass fibre production process. The combination of such innovative applications and the setup of additive manufacturing in the digital factory will result in huge innovation potential.”

3D printing precious metals

Cooksongold AM has been collaborating with EOS for a number of years now, industrializing EOS’ jewelry 3D printers, the M 080 and M 100, and fine-tuning them to be capable of printing precious metals. In fact, it was Cooksongold AM that developed the precious metal parameters that make them compatible with EOS PBF technology.

Cooksongold believes that the ability to 3D print precious metals on an industrial scale, coupled with developing commercially viable novel applications, will prove to be a powerful technology enabler. ITA is also supplementing the work with its own research in the hopes of achieving a “seismic step forward” in the industrial additive manufacturing of precious metals. On top of this, ITA is acting as a key partner in applying the group’s AM expertise to the glass fiber industry.

The partners have set up AMPS (Advanced Manufacturing Process Solutions) to showcase the technology they are working on. The new company will also be used to provide R&D and prototyping services. Upon hearing of the project, glass fiber companies around the world have since joined in, and the project has been structured to cater to every contributor’s needs. All commercially sensitive work will take place in a “cost-sharing” environment free of intellectual property – the partners hope that the novel collaborative method will drive innovation and advance glass fiber production “beyond recognition over the next decade.”

JEC Composites Magazine Special Prize

As a reward for their novel approach, the partners were awarded the JEC Composites Magazine special prize on May the 13th.

Martin Bach, Managing Director of Cooksongold, stated: “I am incredibly proud to be receiving the JEC Magazine Special Prize but even more proud of my team, who have managed to bring together a global collaboration in such a way that it is poised to deliver game-changing material and design innovation and efficiencies in production, that could’ve only been dreamed of a few short years ago.”

Professor Thomas Gries, Director of ITA, adds: “We are excited to be receiving this prestigious award for our work in the field of additive manufacturing for bushings. We truly believe that the developments will be a key enabler for future innovations in the field of glass fibre production, and I am proud of my team of researchers and our collaborators to have made this possible. As an institute developing processes, equipment and machinery, ITA goes beyond just developing fibre and textile products. Digital manufacturing of the bushings allows us to step across existing process innovation borders and allows production and product innovation never seen before.”

This is not the first AM collaboration Cooksongold has been a part of. Late last year, the jewelry maker partnered up with 3D LAB, an official 3D Systems reseller, to develop a compact precious metal powder atomizer. The modestly sized machine is the first of its kind, using a patented ultrasonic plasma atomization process specially tuned for the processing of silver, platinum and gold. Also no stranger to collaborations, EOS is leading a 15 partner European lighthouse project to develop a digitalized AM production line for the automotive industry.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the EOS M 080 precious metal 3D printer. Image via EOS.