The 4th of May saw the launch of the POLYLINE project, a lighthouse project that will bring together 15 industrial and research partners from across Germany to develop a digitalized AM production line. The automated production line will focus on 3D printing serial polymer parts for the automotive sector. By complementing traditional manufacturing techniques with industrial-grade AM technology, the partners hope to produce a number of high-throughput production line systems to advance automotive manufacturing.

POLYLINE has received a total of €10.7M in funding from the German Federal Ministry of Education and Research. It will take place over the course of three years and was commenced at a kick-off meeting at EOS, who is leading the project, in Krailling, Germany.

The POLYLINE project

The design freedom granted by additive manufacturing technology makes it perfect for highly complex bespoke prototyping. As it stands, however, the vertical and horizontal integration of AM into current industrial manufacturing lines is generally difficult due to a lack of standards. The standards aren’t in place due to the relative infancy of AM-specific workflows and processes such as post-processing and part transport. Many of these processes are still highly manual – an issue the POLYLINE project aims to remedy.

On the digital side of things, there is a lack of transparency, a proneness to errors, and limited process chain monitoring capabilities as a result of a lack of interface continuity in the horizontal digital data chain. The project partners believe these hurdles severely limit the potential of AM in existing series production lines.

Scalable AM production lines

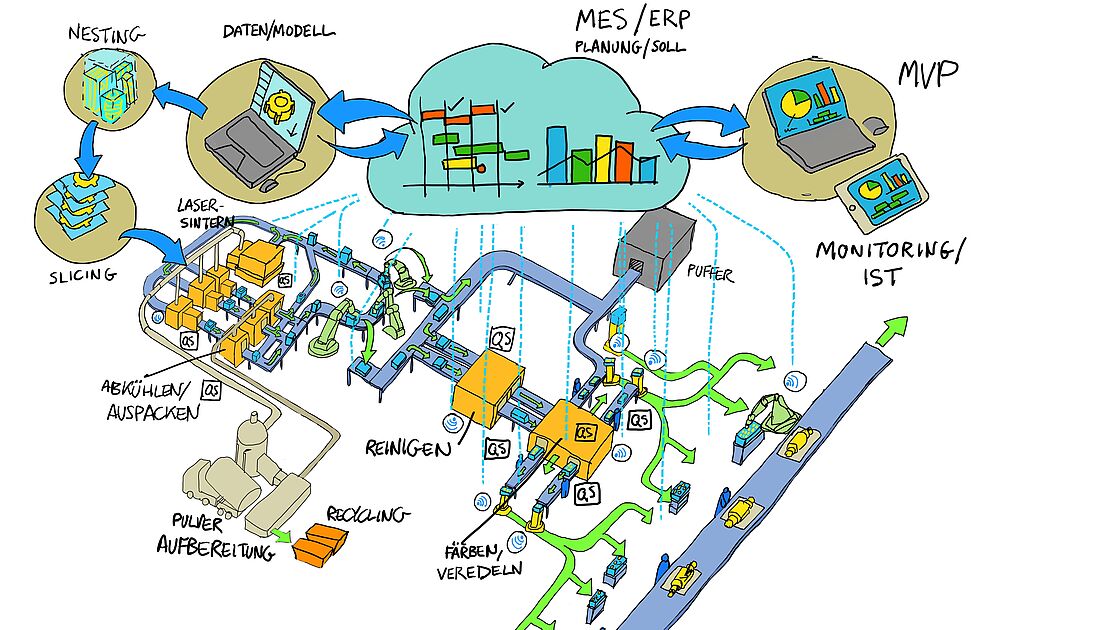

To consider the project successful, the partners will have to develop a “breakthrough” system covering both the digital and physical aspects of manufacturing. They will document and keep a record of all central characteristics and quality criteria from the CAD design to the final physical part. All individual sub-processes (preparation, SLS, cooling, unpacking, cleaning, and post-processing) will be automated and integrate into the production line. According to EOS, this will be the first time all the individual elements of an SLS production line will be linked together in one continuous automated chain.

The hopes are that the holistic approach of the project will be capable of implementing the planned production line with a high degree of maturity in line with the applications it will be used for. According to EOS, the use cases cover individual bespoke parts as well as serial components in greater numbers.

The full list of project partners is as follows: EOS, BMW Group, Grenzebach Maschinenbau, 3YOURMIND, Additive Marking, DyeMansion, Bernd Olschner, Optris, Krumm-tec, Paderborn University, Fraunhofer IGCV, Fraunhofer IML, Dortmund University of Technology, University of Augsburg, and University Duisburg Essen.

The issue of AM standards is a long-standing one which the POLYLINE project aims to fix – at least for automotive. Earlier this year, a number of industry leaders gathered in Munich for the 2nd TÜV SÜD Additive Manufacturing Conference to discuss the implementation of industrial additive manufacturing through standardization and digitization. More recently, AMT and Leering Hengelo partnered up to launch two new automated de-powdering systems for 3D printed parts. Although it does not cover the entire process chain, the PostProDP range aims to automate the excruciatingly tedious and manual post-processing associated with PBF components.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the consortium meeting of the 15 partners in Krailling. Photo via EOS.